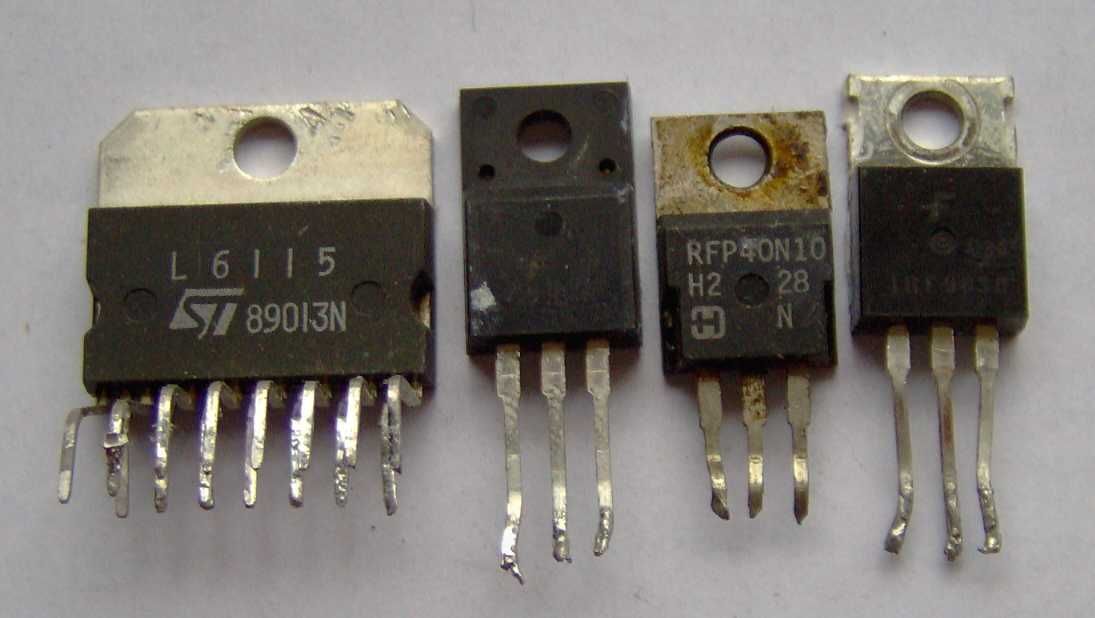

Many of our daily electronic devices rely on transistors one way or another. Transistors are electronic components used to control the flow of current passing through a device. They act as electronically controlled switches turning on and off, providing binary signals that devices can use to process data.

As you can imagine, transistors are present in almost every electronic device you are using daily. Transistors can be made based on several raw materials. However, manufacturers prefer using silicon above any other material. Here are three reasons why.

1. Silicon Is Inexpensive

Silicon is the second most abundant element on the earth's crust after oxygen. Although pure silicon is rare, materials like silica (SiO2) are readily available in plain view at the beach or other sandy environments.

You could usually identify silica on the beach as the shiny grains that sparkle when you handle sand on a sunny day.

The beach, however, is not a good place to source silicon. Beach sand has way too many impurities that the ratio of silica and other materials isn't ideal. Manufacturers would either buy from silicon providers or quarry the materials themselves at places where silica concentrations are dense.

When compared to other metalloid materials, silicon has a much easier and straightforward way of purification. Since silica is only silicon and oxygen combined, all you need to do is remove the oxygen particles, and you're left with pure silicon.

The process is to introduce carbon with the silica on a furnace heated up to 3,632 degrees Fahrenheit (2,000 degrees Celsius). The energy from the heat would break the silicon and oxygen apart. Based on atomic structures, oxygen is more likely to bond with carbon, leaving highly concentrated silicon in the process.

2. Silicon Is Used to Make MOSFETs Used in Processing Chips

MOSFETs (metal-oxide-silicon field-effect-transistor) are the ideal type of transistor to make processors and memory such as CPUs, RAMs, SSDs, and flash drives. As the name implies, MOSFETs are made from silicon. There are several qualities of MOSFETS that make them the ideal components to make processing chips. These would include:

- Power Efficiency. As opposed to other transistors, MOSFETS are controlled by voltage and not current. With voltage controlling the gate and only minimal amounts of current passing through the transistor, less energy is consumed.

- High-Frequency Switching. Using only minimal current to switch the MOSFET ON and OFF makes these types of transistors ideal for high-frequency applications such as on processors.

- Low Electromagnetic Interference. Low currents prevent MOSFETS from producing electromagnetic interferences that may affect other components beside it. Without worrying about electromagnetic interference, engineers were able to package them in such dense formats.

- Natural Insulation. Silicon has properties that make naturally occurring insulation. Another reason MOSFETS can be packaged densely is through its naturally occurring insulation.

- Great Thermals. High currents make conductors hot. Since MOSFETs don't use much current, they don't heat up as much–unless you overclock them, of course.

- Overclockable. Running with low heat also means that MOSFETS used as switches can be throttled much more when compared to other types of transistors.

With its many advantages and applications, MOSFETS are the transistor of choice when making electronic chip components, but why use silicon to make field-effect transistors in the first place? Why not other elements?

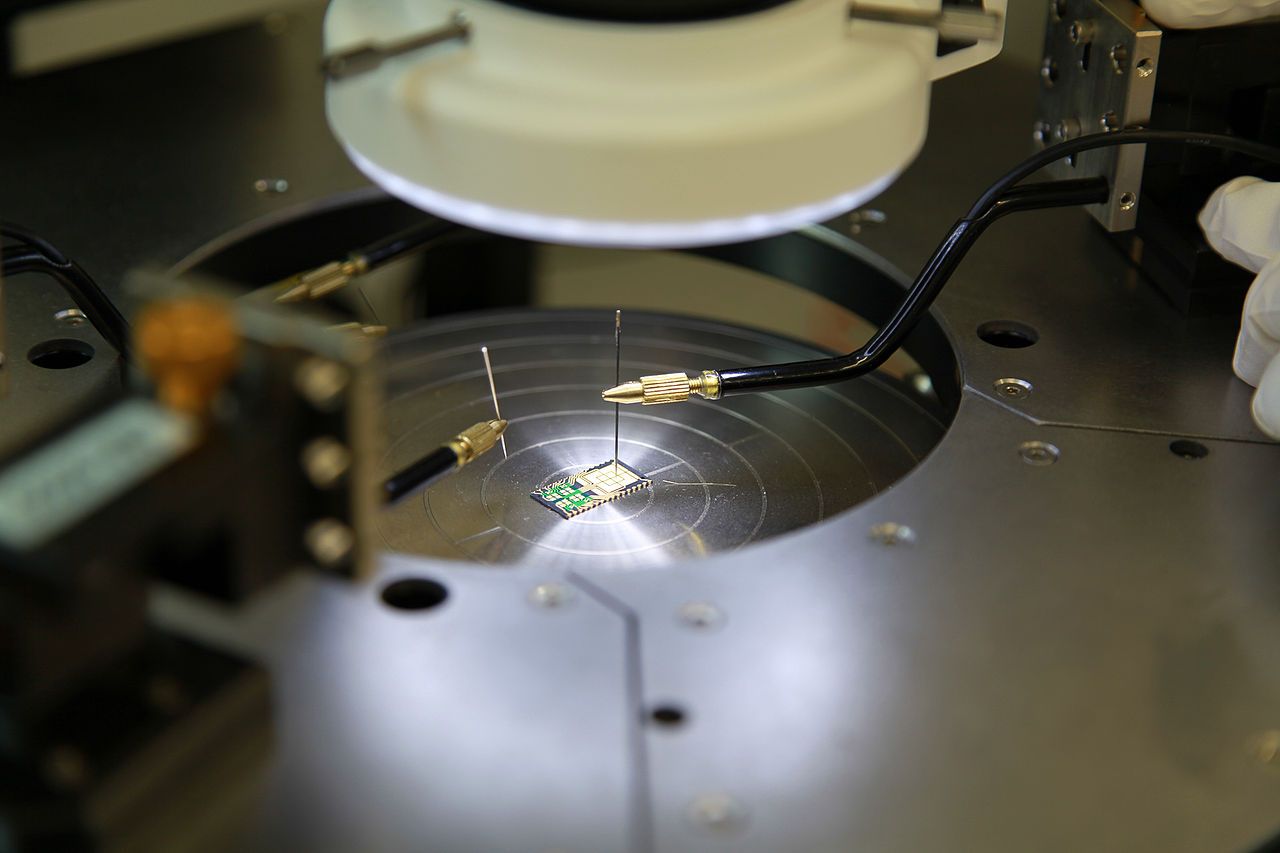

When making transistors, manufacturers need to use an element with semi-conductive properties such as silicon. Semiconductors are metalloids that are neither a conductor nor an insulator. They still allow current to flow through them, just in a very inefficient way.

Pure silicon is naturally a bad conductor. However, by adding impurities like boron and phosphorus, engineers were able to alter the conductive properties of semiconductors, allowing transistors to switch from conductor to insulator when voltage is introduced, much like a switch.

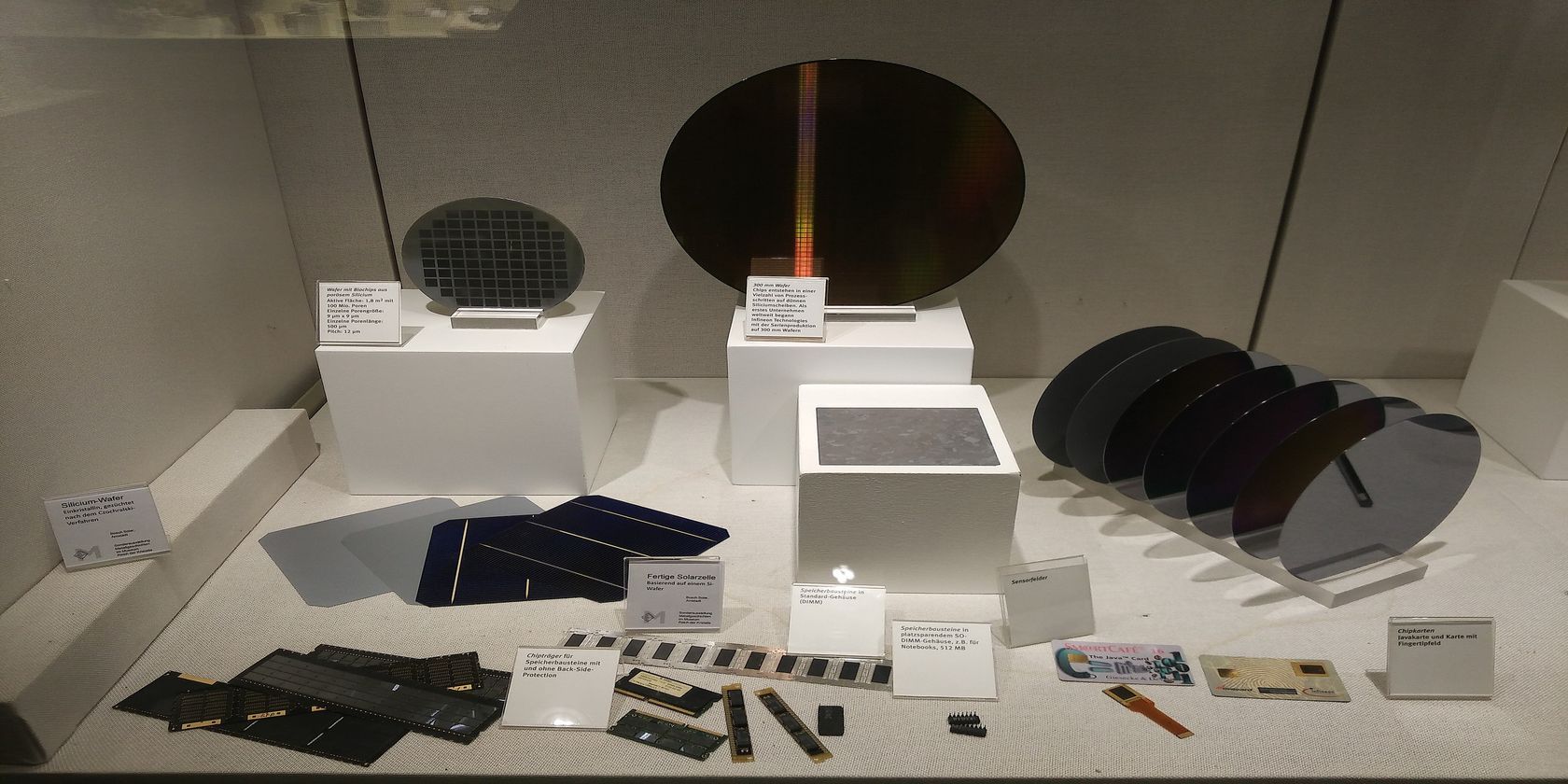

3. Easy Fabrication Process

Although other semiconductors have properties that can make better field-effect transistors, silicon is still the preferred material due to its ease of fabrication. This means less complexity which translates to less money spent on specialty tooling and extra processing.

One of the main reasons silicon is easier to work with is due to its high melting point. The melting point of silicon is 2,570 degrees Fahrenheit (1,410 degrees Celsius). A material with a high melting point is essential to microchip manufacturing, especially if they implement gate-last manufacturing, which introduces a dummy gate used as a placeholder to make a mold where the actual active gate is to be installed.

Another property that makes silicon is easier to fabricate is its naturally occurring insulating property. When oxygen is introduced to the top silicon layers, they form a layer of metal-oxide-silicon (Glass). Glass is an excellent insulator even in thin layers, allowing manufacturers to have free insulation, saving them a ton of cost and manufacturing time.

Aside from being cheap, silicon production is also much more significant than any other semiconductor production in the market. With silicon readily available, manufacturers don't have to worry about running out of raw materials to work with, again saving time and making more microchips, which translates to more profit.

Silicon Is Everywhere

Silicon is the ultimate semiconductor that allowed our world to become prosperous and be the technological behemoth that it is today. It is responsible for making certain technology possible and is also the reason why the majority of the world is able to enjoy technology.

Although silicon has many manufacturing advantages that make the tech industry more profitable, you, the consumer, also benefit from silicon manufacturing. Electronics devices such as smartphones, computers, gaming consoles, televisions, CMOS cameras, and all other smart devices are made affordable due to the low cost of raw materials and easier manufacturing.

Silicon is such a big part of our life that, ironically, silica (impure silicon) has to be quarried from sandy environments, while pure silicon can be found scattered all over our household.