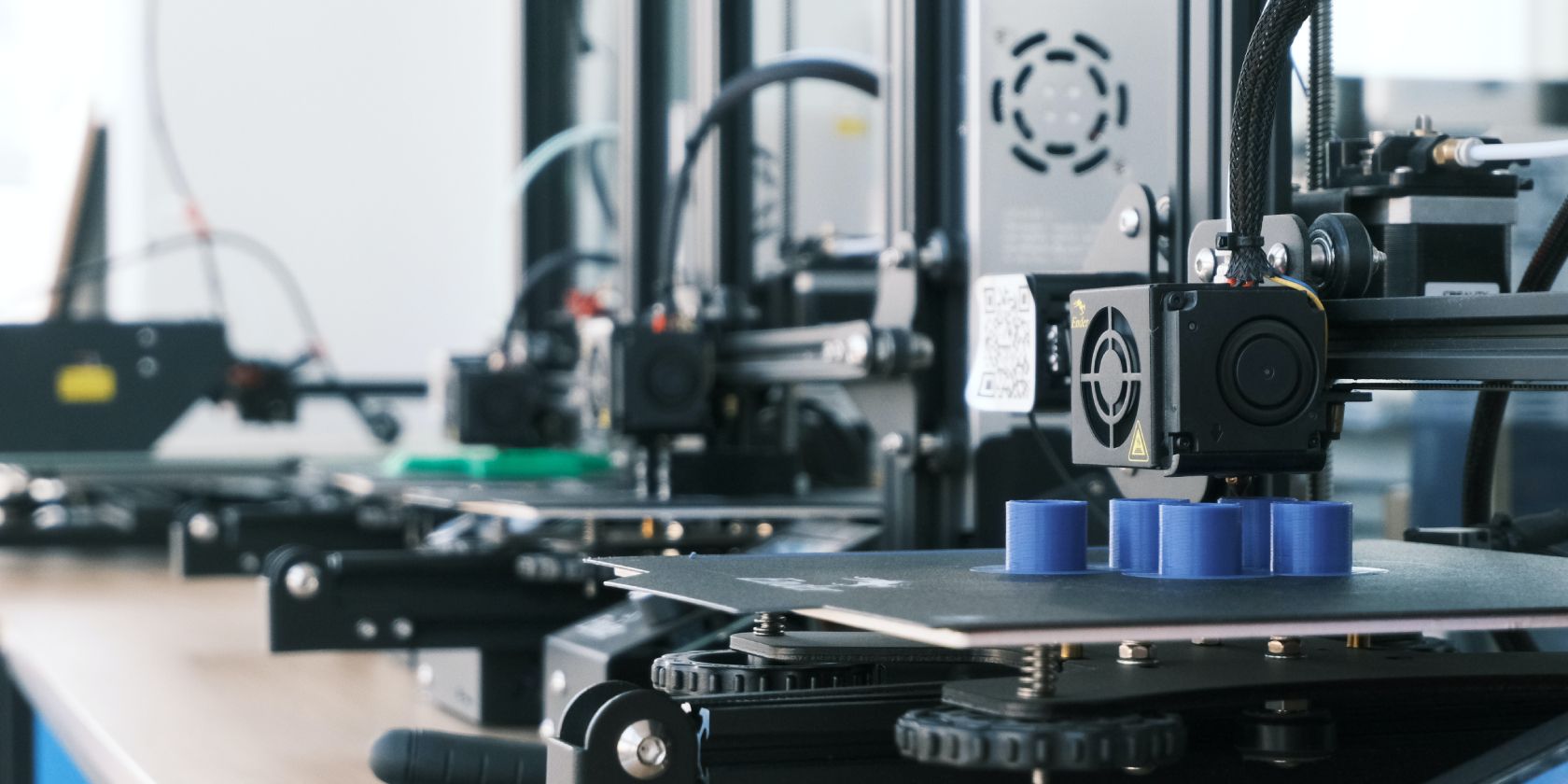

It might not be obvious given the sheer volume of technological advances taking place these days, particularly as the topic of AI crowds out other headlines, but the area of 3D printing in healthcare is rapidly evolving. Every week, companies release details on new innovations they're working on to 3D print human body parts, such as kidneys and other organs. And it doesn't stop there.

3D printing goes beyond printing uniquely-shaped trinkets, with far-reaching implications for medical technology. Here are some of the fascinating ways it is being utilized in healthcare.

1. 3D-Printed Prosthetics

With 3D printing, the market for custom limbs is growing, and many organizations are capitalizing on the demand. Examples include Open Bionics (whose slogan is "Turning Disabilities Into Superpowers"), e-NABLE (a global community of volunteers making free and low-cost prosthetics for children), and UNYQ (a company that makes prosthetics that could also be considered works of art).

If you are family with 3D printing in the healthcare space, you've no doubt come across a multitude of inspiring anecdotes describing how people have used 3D-printed prosthetics to not only regain the use of limbs but also achieve awe-inspiring feats such as sprinting across finish lines with the aid of tailor-made 3D-printed blades.

At the heart of these stories lie advanced materials and technologies. 3D-printed prosthetics are crafted from lightweight and durable plastics which are often combined with silicone, TPE, rubber, and more to merge comfortably with the human body.

As technology becomes more accessible and creators find new ways to build prosthetics, there's no doubt that we'll continue to see some cool advancements in the coming years.

2. 3D-Printed Implants

There are many technologies shaping the future of healthcare and many ways implantable technology could change health and wellness. At the same time, 3D-printed implants are starting to play more and more of a role in medical scenarios. Think titanium implants for bone injuries, cranial plates, and even spinal fusion cages. It may sound like something out of a Marvel comic, but these innovations are happening right now.

Companies operating in this space include Materialise, Stryker, and 4WEB Medical, to name a few. These companies are pushing boundaries in mechano-biology by offering personalized and precise solutions to once-daunting medical challenges. For example, 3D-printed implants can be used to help reconstruct facial bones or repair spinal damage.

3D-printed implants typically use materials like titanium or cobalt-chromium, known for their strength and biocompatibility. When combined with 3D printing techniques like Selective Laser Melting (SLM) or Electron Beam Melting (EBM), companies can manufacture custom-made implants that can seamlessly integrate with a patient's unique anatomy.

The beauty of these 3D-printed implants lies in their potential to drastically improve patient outcomes. There are beautiful stories posted across the internet of people who've suffered severe injuries and have had the bones in their faces reconstructed with custom-made 3D-printed implants. There are also examples of people who've undergone complex spinal fusion surgeries made possible by 3D-printed implants.

If you're wondering what the future holds, bioprinting is one example. This cutting-edge technology involves using a patient's cells to create living, functional tissue for implantation. While still in its infancy, the possibilities are huge (think custom-made organs).

3. 3D Printing in Drug Delivery

3D printing in healthcare yields another remarkable application: drug delivery. Gone may be the days of one-size-fits-all medication. The future is all about personalization, and 3D printing is helping to lead the charge.

Companies like Aprecia Pharmaceuticals and FabRx are shaking up the industry with their novel approaches to drug manufacturing. By leveraging 3D printing technologies like fused deposition modeling (FDM), these companies can create customized pills tailored to each patient's specific needs.

More specifically, with 3D printing, it's possible to create complex pill structures that control the release of active ingredients. Porous pills manufactured this way dissolve rapidly, while multi-layered pills can release different drugs at different times.

In terms of future applications, think about elderly patients with multiple prescriptions who might be able to take a single, custom-made pill that combines all their required medications.

4. 3D-Printed Tissues and Organs

3D printing is used to manufacture a wide range of products; you can even 3D print car parts. However, 3D bioprinting is truly next level. Scientists are working toward printing things like human skin for burn victims and hope to one day be able to print mini-organs for drug testing. Companies like Organovo and Prellis Biologics are two companies making advancements in 3D-printed human tissue.

At the core of 3D bioprinting lies a complex process that involves layering cells, also known as bio-ink, in precise patterns to create living structures. Picture a 3D printer equipped with multiple syringes, each filled with a different type of cell. The printer deposits these cells, one layer at a time, until a fully-formed tissue or organ takes shape.

One of the big news stories in 2022 featured the work of 3DBio Therapeutics, a company that successfully 3D-printed a human ear. While this may seem like a relatively simple part of human anatomy—and it is—scientists are working to refine bioprinting techniques, to create fully functional, transplantable organs. We're not quite there, but every day we get closer to a world where organ waiting lists become a thing of the past.

5. 3D-Printed Medical Devices

Another example of how 3D printing is being used in healthcare is in the development of customized surgical instruments.

In the past, surgeons were often limited by the availability of standardized tools, making it difficult to perform complex procedures with the desired level of precision. With 3D printing, surgeons can now access tailor-made instruments designed specifically for a particular procedure or patient's anatomy. These bespoke tools can lead to increased accuracy, reduced operating time, and ultimately, improved patient outcomes.

For example, retractors are essential in surgeries to hold back organs or tissues, providing surgeons with a clear field of view. With 3D printing, retractors can be customized to fit a patient's unique anatomy, ensuring optimal exposure while minimizing trauma to the surrounding tissues.

Embracing the Future of 3D-Printed Technology

It's amazing to see how technology is positively impacting the lives of patients. From customized prosthetics and implants to drug delivery, tissue engineering, and innovative medical devices, 3D printing is truly pushing healthcare into new areas.

Moving forward, this kind of transformative technology will undoubtedly lead to once unimaginable breakthroughs, making a positive impact on the lives of even more individuals around the world.