Prusa Research’s printers bridge the gap between expensive pro-sumer 3D printers and their cheap Chinese counterparts. And they do this while delivering the thorough reliability and support of the former, thanks to the Czech 3D printing company’s open-source roots.

The long-awaited Prusa XL 3D printer has now been formally unveiled and it’s fundamentally different from anything Prusa has made so far. Read on to find out more about the printer in our post-reveal analysis.

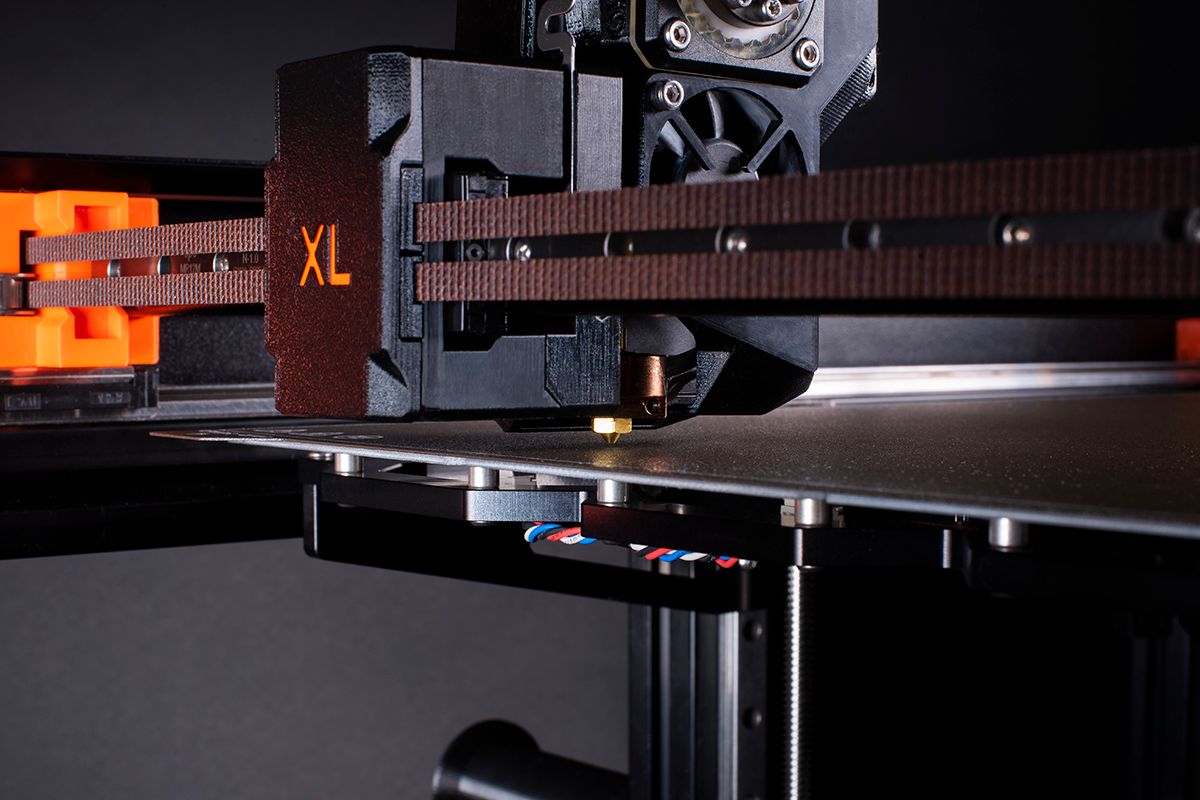

Cycloidal Gear Extruder for Better Extrusion

Extruder design is the single largest contributing factor to 3D printer performance and print quality. Printing fast calls for high filament flow rates, which requires extruders to force filament into the nozzle at extremely high pressures. The E3D Hemera direct drive extruder, for example, can generate 22lb (10kg) of thrust.

That amount of force creates problems because you’re pushing relatively soft and brittle plastic filament through metal drive gears. That’s a recipe for stripped filament and skipped gears. Good extruder designs therefore use large-diameter drive gears to distribute the pushing force along a longer segment of the filament.

Prusa XL’s bespoke new extruder follows these design fundamentals and pushes them to their very limits.

The drive gear showcased in the Prusa XL, for example, is the largest we have ever seen in any extruder. Unlike traditional designs, it pushes the filament against two bearings, which forces it to follow an effectively longer path around the drive gear.

The new extruder gear design should give the Prusa XL unparalleled filament grip.

Prusa XL Embraces CoreXY Kinematics

The Prusa XL fundamentally diverges from the i3 printer design by incorporating a relatively new CoreXY motion system. Developed by the MIT Media Lab in 2012, the CoreXY design has served as the foundation for open-source DIY 3D printers such as the Rat Rig, HevORT, HyperCube, and Voron—all of which embarrass significantly more expensive printers in every conceivable performance metric.

The Prusa XL seems to have incorporated the CoreXY motion system without making any significant changes. Our comprehensive Voron guide covers the virtues of the CoreXY design in detail, but its belt-driven motion system makes the moving print head extremely light. While existing Prusa i3 printers must haul heavy stepper motors along the cardinal axes, the same in CoreXY printers are not just stationary but they also enhance rigidity by doubling up as stressed members of the frame.

This allows the stepper motors to deliver added structural rigidity in CoreXY designs, instead of otherwise slowing down moving gantries by the virtue of their weight in traditional 3D printers. Not surprisingly, CoreXY printers dominate the world records for fast printing.

The Prusa XL’s CoreXY underpinnings virtually guarantee it groundbreaking improvements across every performance parameter over the outgoing models. The inclusion of high-quality linear rails—which form a substantial portion of the XL’s bill-of-materials according to Josef Prusa—should also translate into high precision and long service life for the printer’s motion system.

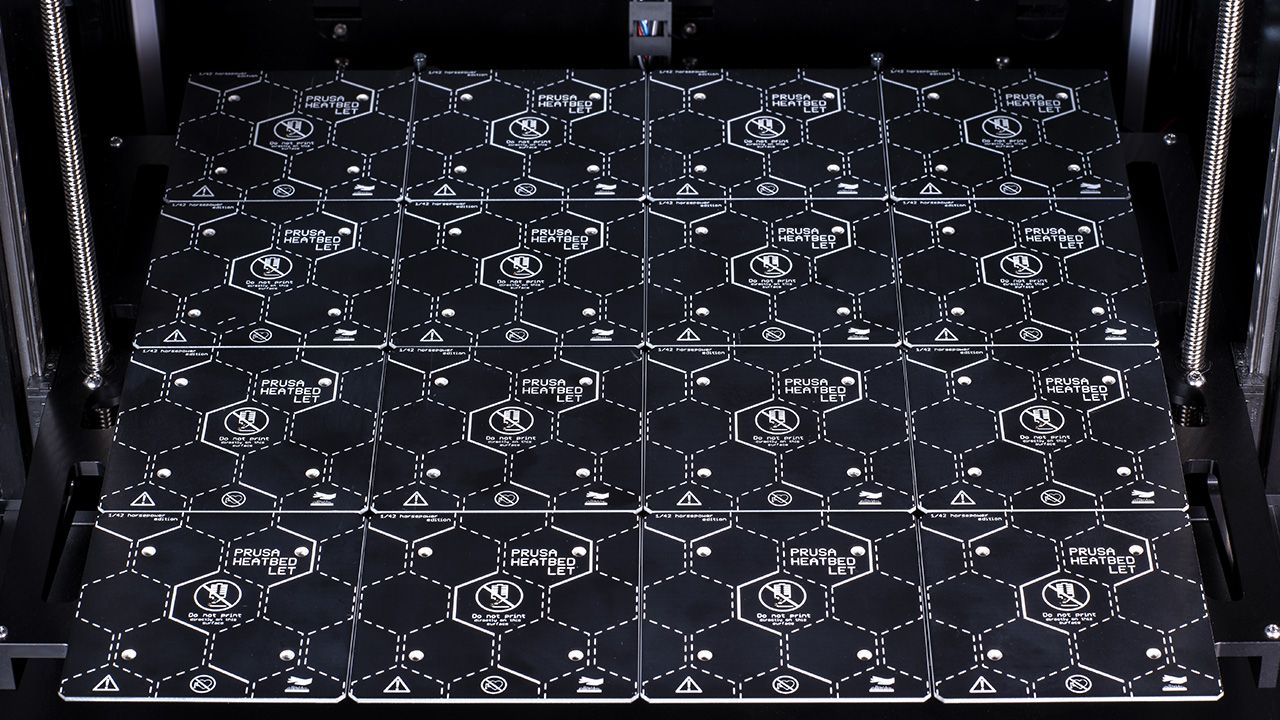

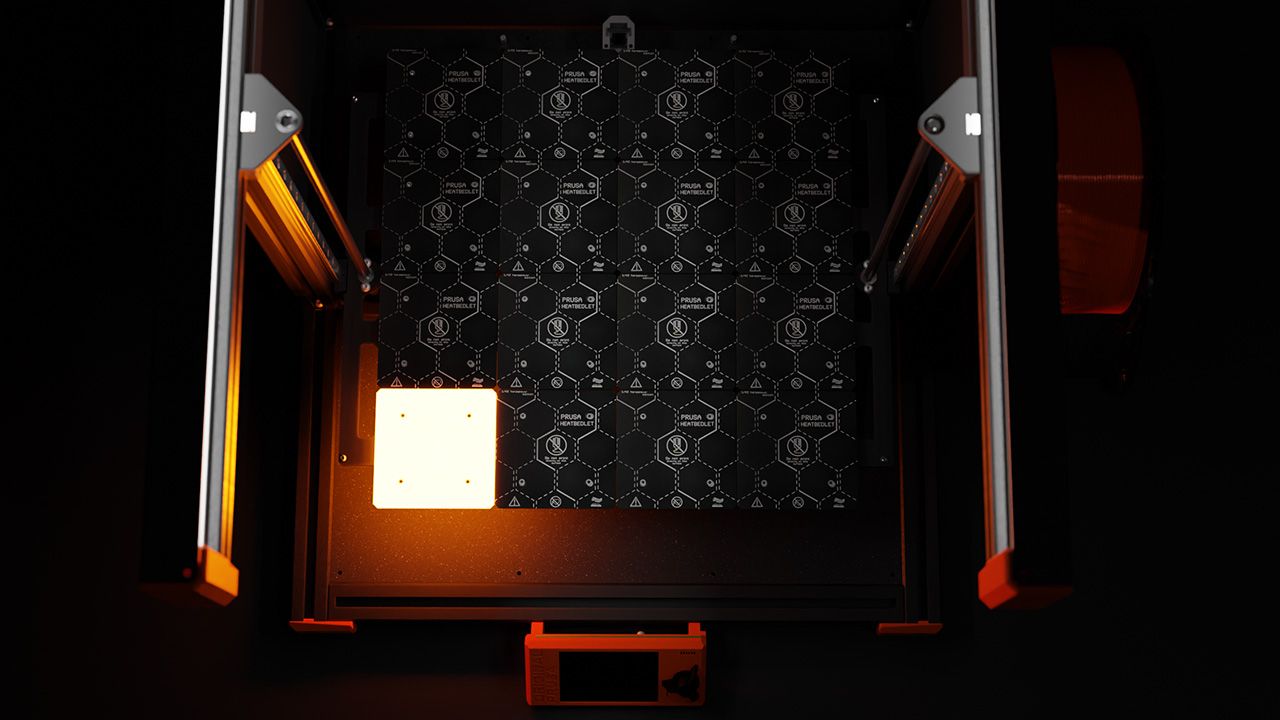

Modular Bed: Tighter Control with Power Efficiency

The Prusa XL’s 36 cubic centimeter build volume is more than four times that of the Prusa i3 MK3S. However, that also entails larger beds. This, in turn, poses two major challenges—warping and high-power consumption.

The printed circuit board-based (PCB) heated beds employed in Prusa and other mainstream 3D printers are cheap, lightweight, and power efficient. Unfortunately, their lack of rigidity makes them prone to warping on account of thermal expansion. Cast aluminum beds are immune to warping, but they are prohibitively heavy and expensive at such large build volumes.

Prusa, however, engineered its way around this problem by dividing the bed into 16 individually-heated bed segments, replete with expansion gaps to alleviate warping. Because each bed segment can be discretely controlled with its own heater circuit, you no longer have to heat up the entire bed for smaller prints.

This also allows massive reduction of power supply load, since power can be pulsed into alternate bed segments in a checkerboard fashion at several times a second. The PSU effectively has to deal with only half the total heater load thanks to the wonders of pulse-width modulation.

The modular bed also promises unprecedented thermal uniformity thanks to discrete temperature sensors assigned to each bed segment. This works by running the bed corners hotter since they experience higher radiative heat losses.

Should You Pre-Order the Prusa XL?

Instead of launching the XL printer outright, Prusa has chosen to take the Kickstarter-esque route by introducing a refundable $200 pre-order deposit before its unspecified launch sometime in 2022 after manufacturing commences in Q3 next year.

A company of Prusa’s stature shouldn’t ideally need to raise funds in this manner, but should you nevertheless bother with the pre-order for a printer that starts at $2000?

The Prusa XL incorporates compelling features such as completely automated bed tramming with the help of load cell sensor-equipped nozzles. The nozzle design itself has been co-developed along with E3D to integrate the same killer features of the E3D Revo nozzle system we have covered in detail.

For anywhere between an extra $500 and $1500, it can also transform into a promising tool-changer system akin to the E3D ToolChanger. And it makes the process seamless and manual calibration-free with tool touch-off systems borrowed from CNC machines.

There are other good reasons to consider the XL, including a large array of sensors to detect heat creep and filament jams, in addition to a nifty approach to modular electronics that makes adding extra tool-heads a potentially flexible and cost-effective affair.

Our Recommendation: Wait for Launch

The Prusa XL seems to be a formidable 3D printer based on the specifications revealed so far. However, we still recommend waiting until the first independent reviews to avoid potential teething troubles.