Print-in-place 3D printable models are objects with moveable parts that can be printed as a single piece. Print-in-place parts make it possible to create complex mechanisms all in one go, as you don’t have to put multiple 3D prints together to have moving parts.

There are loads of examples of excellent print-in-place 3D printables around the web. You can find a collection of free print-in-place files below, all of which provide a good starting point for those getting into this type of printing. But before we dive in, let's make sure your printer is configured properly.

The Right Settings for Print-in-Place 3D Prints

Print-in-place parts make it easy to create mechanisms with moving parts, but you have to tune your 3D printer settings for the best results. Tolerances are crucial when 3D printing print-in-place parts. Your machine needs to be accurate enough to leave fine spaces between moving parts, and the wrong settings can easily leave your print welded solid. Keep this in mind no matter the type of printer you use. You can learn more in our article on FDM printer settings.

Now let's dive into some specific settings.

3D Printer Nozzle/Resolution

The print resolution of an FDM printer is limited by the size of the nozzle being used. A wider nozzle will struggle to produce the fine detail required for moving joints and other moving parts. Thankfully, you can usually reduce the size of your nozzle by adding a new one to your printer.

SLA and other resin-based 3D printers don’t use nozzles, instead relying on different types of light to create prints. The vast majority of modern resin 3D printers have a dot size/resolution fine enough to produce good results with any print-in-place project.

Object Scale

If the spaces between moving parts are smaller than the resolution of your printer, it will be impossible for the parts to move when the print is finished. It’s always best to 3D print print-in-place parts at the scale they are designed for.

3D Printer Temperature

Different 3D printer materials react in different ways to heat. Some filaments will suffer under or over extrusion at the wrong temperatures, causing moving parts to fail. You may have to test the best temperature for the filaments you buy, and print-in-place parts can be a great way to do this. Smooth moving parts will show that your temperature is just right.

Support Materials

Some slicer software places supports better than others. You should always check the positioning of your supports to ensure that they won’t cause moving parts to lock in place. Using water-soluble support materials will solve this issue, but you will need a multi-material printer for this to work.

Now with that out of the way, let's get printing.

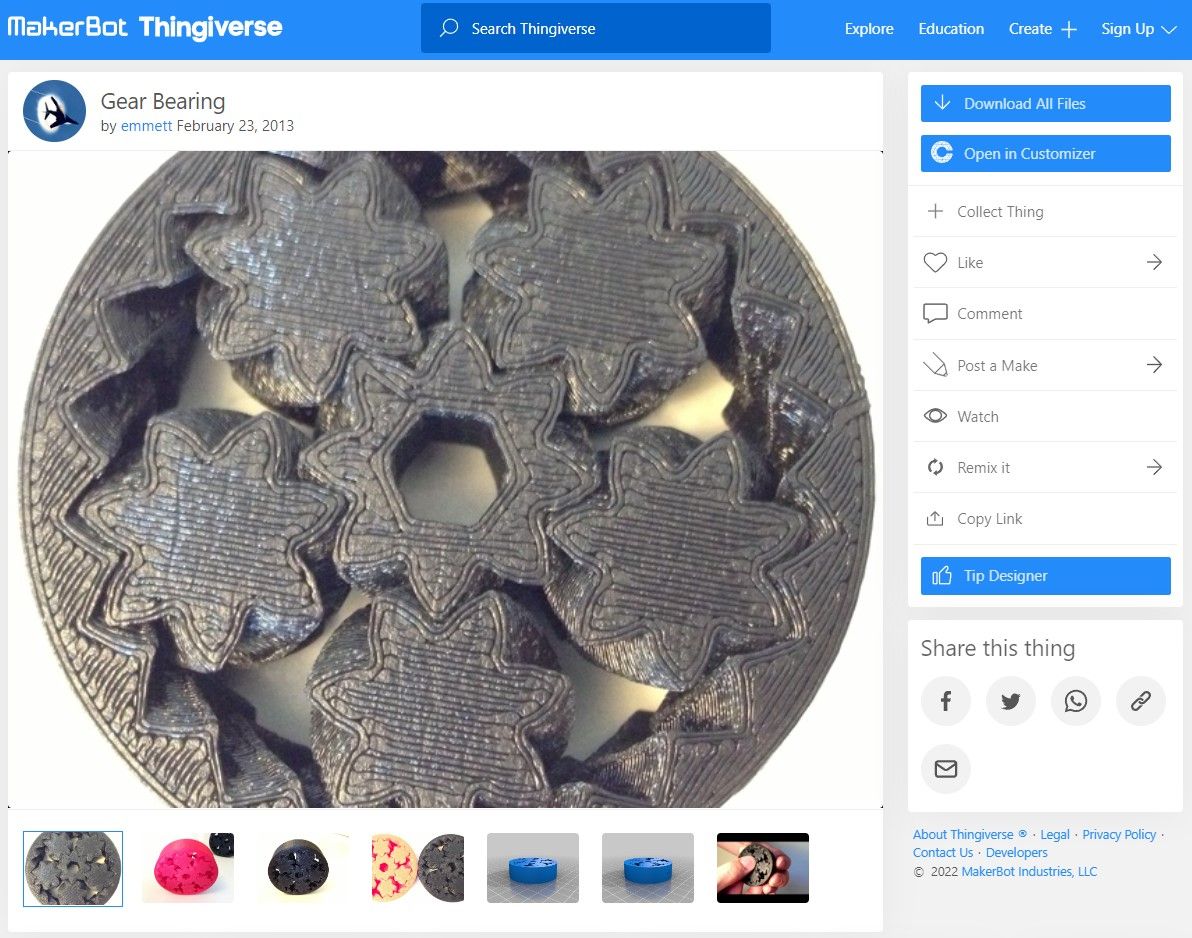

1. 3D Printable Print-in-Place Gear Bearing

3D printing a standard ball bearing tends to come with bad results. FDM 3D printers aren’t great at printing spheres, and adding metal balls adds to the construction time. This 3D printable gear bearing solves this problem, replacing balls with gears that lock together. What’s best, though, is that this part is a print-in-place part.

As with many print-in-place parts, this gear bearing will be fairly stiff at first and will take some time to loosen up. Unless using high-strength filament materials this bearing is best as a fidget toy and won’t perform well under load.

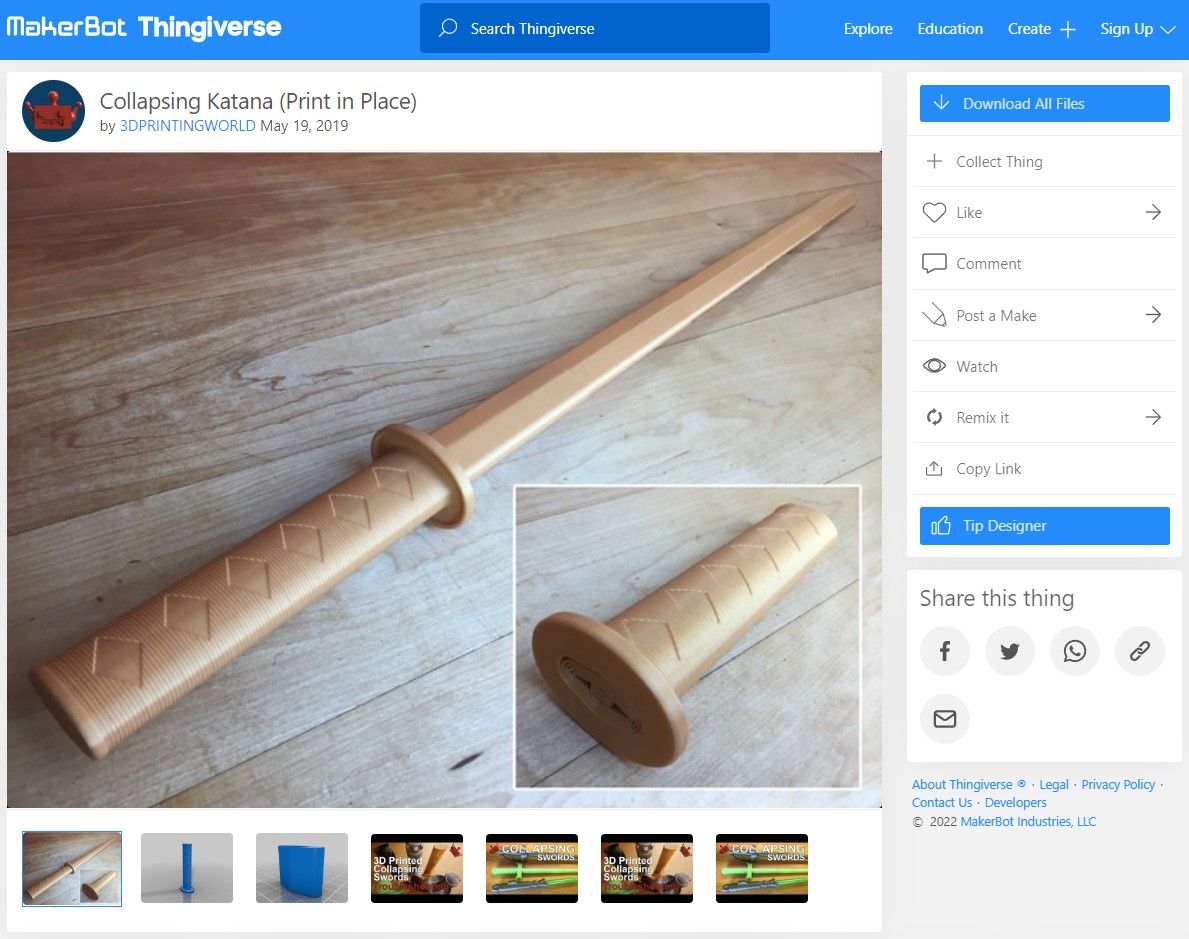

2. Print-in-Place 3D Printable Collapsing Katana

Picture the light saber toys you saw as a child. The ones with telescoping blades that extend with a flick of your wrist. This print-in-place collapsing katana follows the same concept, only you can print it for yourself at home.

The blade is made from 5 segments that nestle comfortably inside the katana’s handle. The sword can be printed collapsed, making it suitable for the smallest of printers. The maker of this part has also made a range of other collapsing 3D printable swords for you to try.

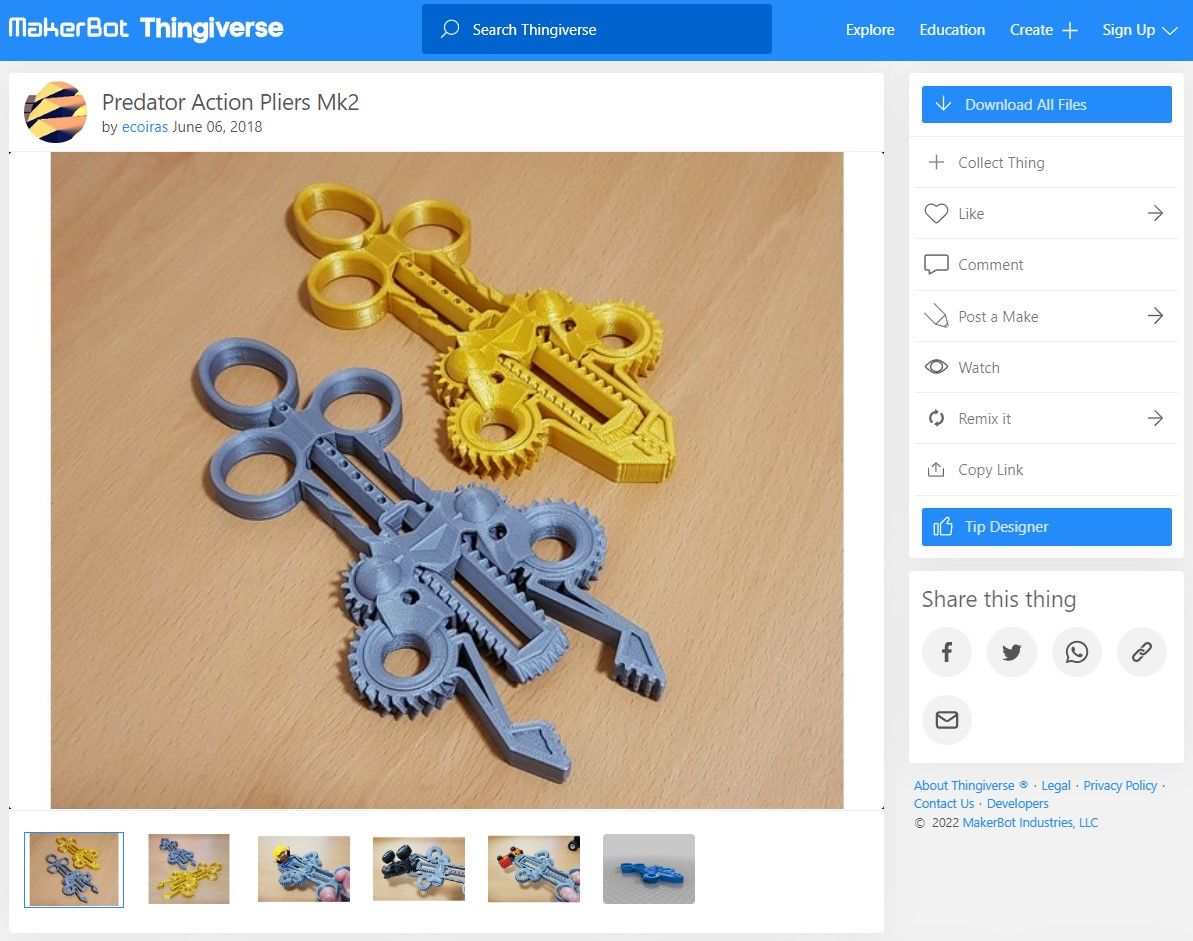

3. Print-in-Place Action Pliers

This next print-in-place project melds functionality with fun. Grab toys have long been popular amongst adults and children alike, creating the basis for loads of different games. These print-in-place action pliers are made to be 3D printed without supports or other additions and are ready to be used as soon as the print is over.

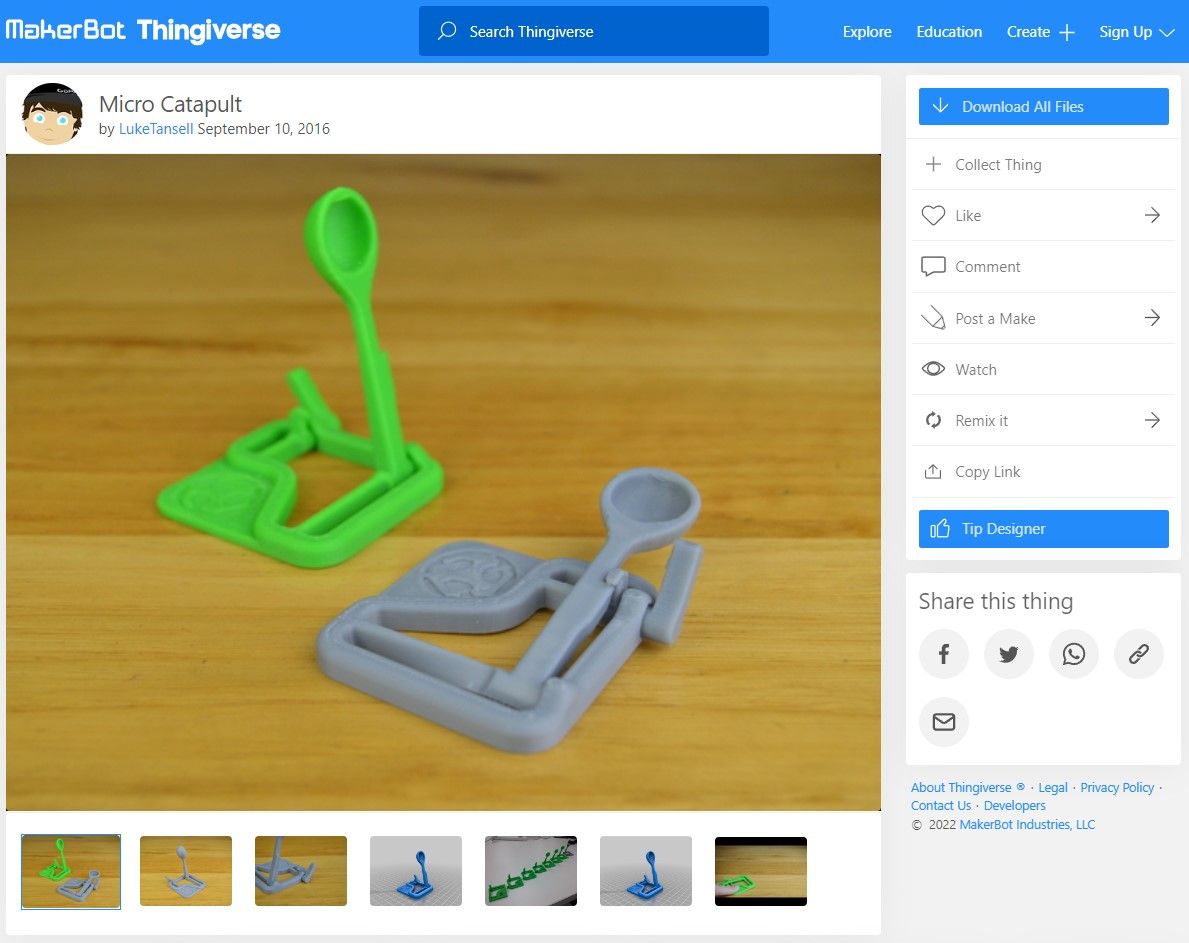

4.Tiny Print-in-Place Desk Catapults

As the perfect toy for any office space, this print-in-place catapult design has become extremely popular over the last few years. At its default scale, this tiny artillery piece can fire pieces of paper, plastic, and other debris more than two meters.

You can raise the scale of this print-in-place project to produce a catapult with more oomph. Using stiff materials like ABS is a good idea, as this will ensure that the spring material doesn’t deform over time. Adding toys to your desk can improve productivity, along with being loads of fun.

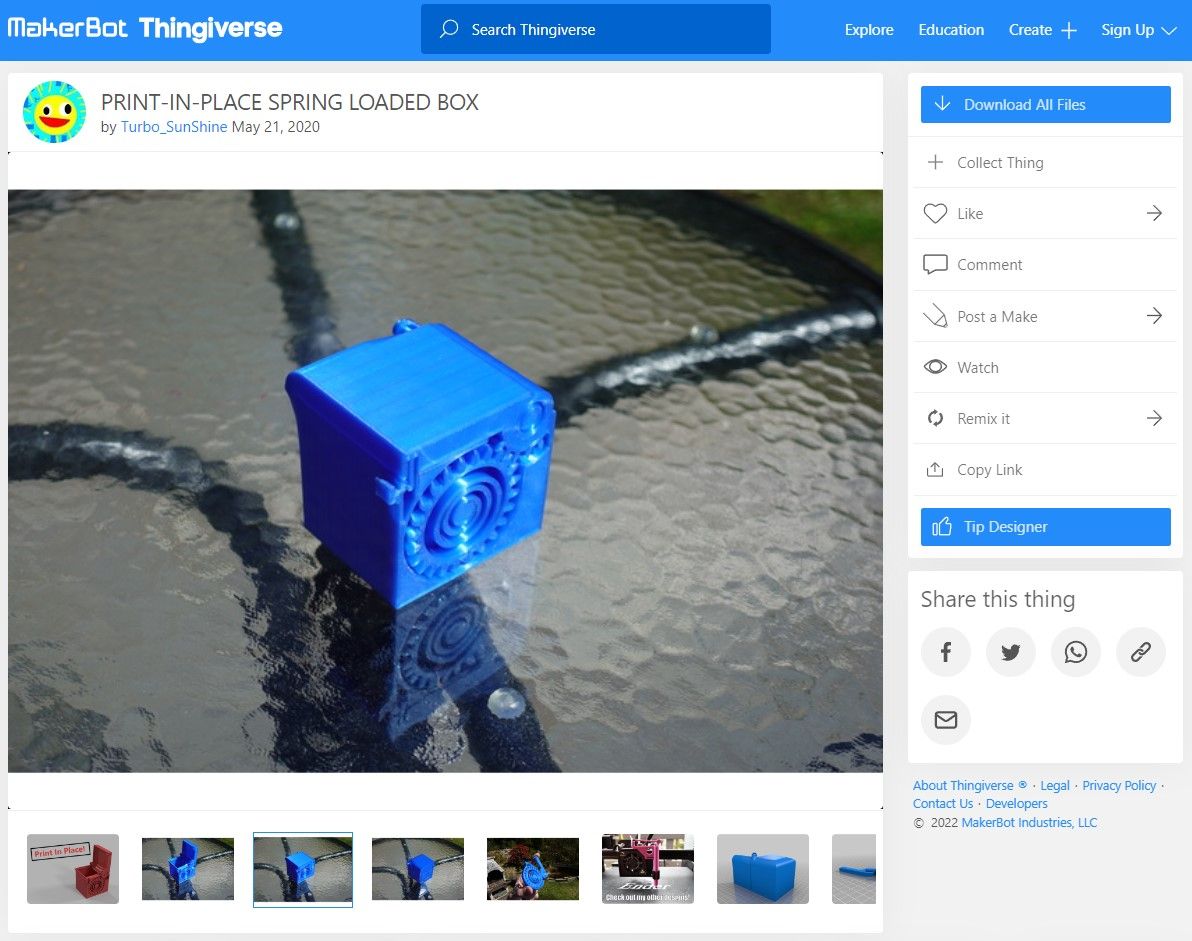

5. Spring-Loaded Print-in-Place Boxes

This next design is as smart as it is useful. The small box has a latching lid that keeps it firmly closed, along with a spring gear that holds the lid open when the latch is pressed. The spring gear is situated on the outside of the box, giving it a unique look that is sure to catch your friend’s eyes. This is another piece that can be scaled up to give you different results.

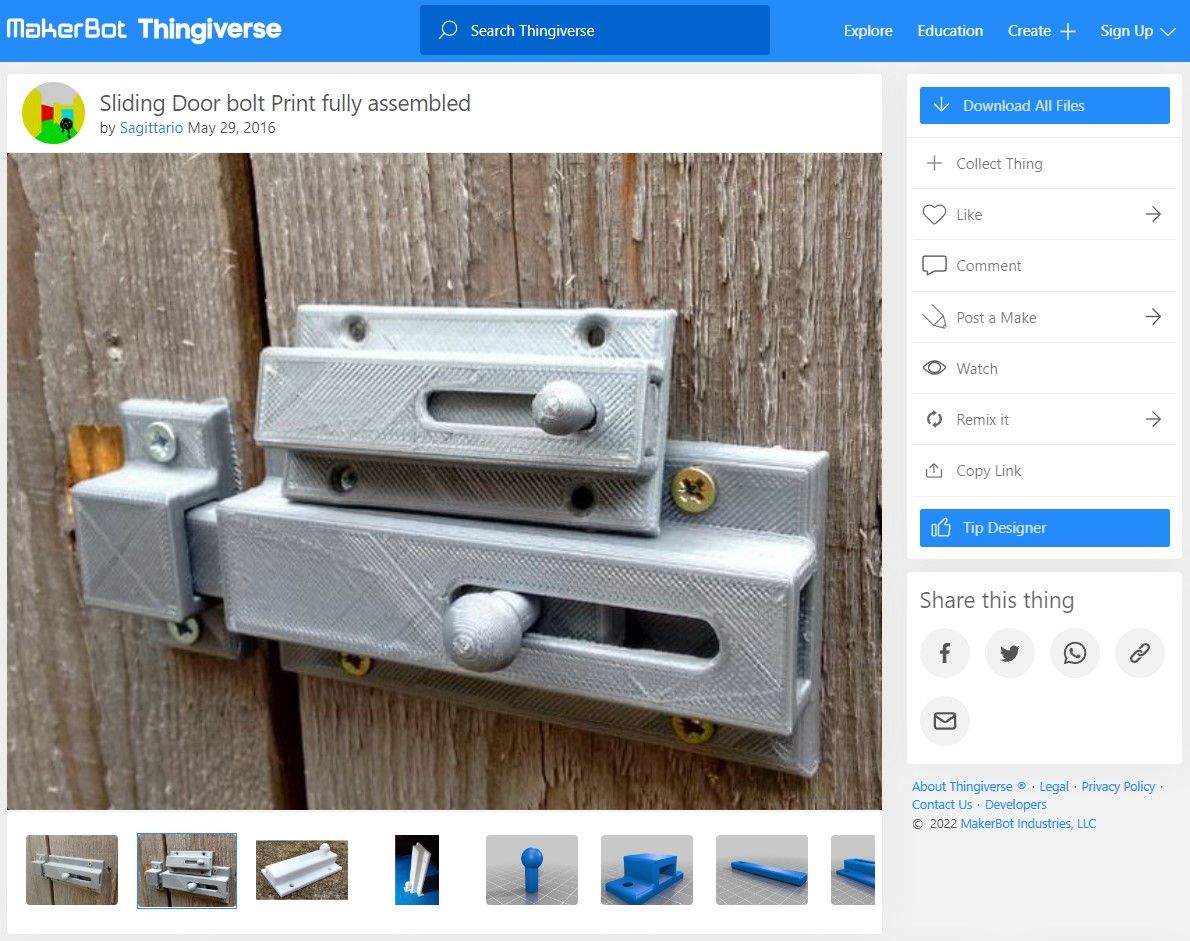

6. Print-in-Place Sliding Bolt Locks

This sliding bolt lock project is designed to allow users to scale the part up without changing its qualities. The whole piece can be printed all at once, but you can also print individual parts if you want to have spares available. Of course, though, like other print-in-place parts, you should avoid scaling this one down.

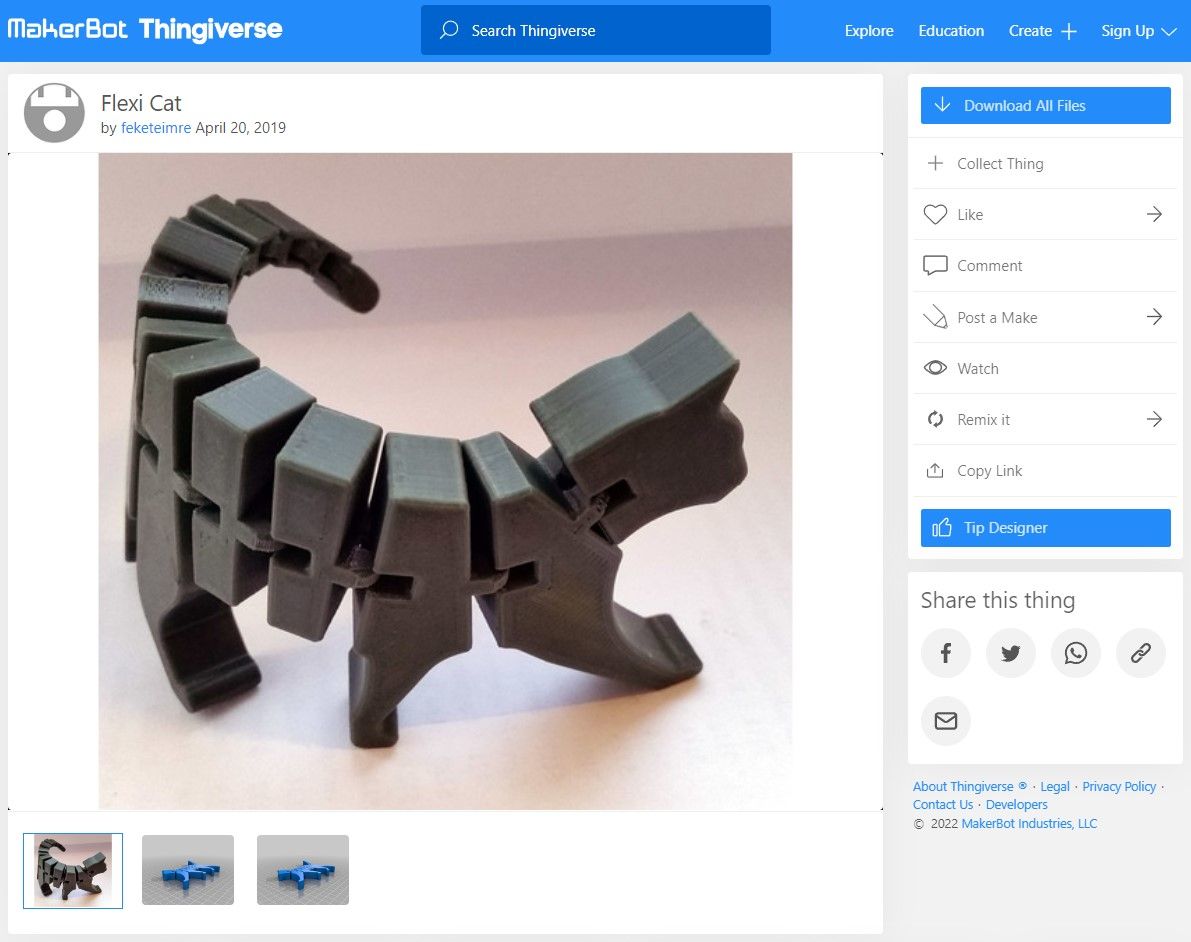

7. Print-in-Place Flexible Animals

Print-in-place dragons became a viral sensation in 2021. The files for 3D prints like this often come with a premium, though plenty of free flexible models of other animals exist. This 3D printable Flexi Cat is a great example of this, giving you a fast and easy print with moving parts that doesn't have to be put together. Alternatively, this Flexi Rex is a cute addition to any dino lover's collection, and you can download it for free.

The Benefits of Print-in-Place 3D Printer Parts

Alongside the files you can find online, designing your own print-in-place parts will provide a valuable learning experience. You will be surprised to find just how many mechanisms can work when they are printed as a single file.

3D printing is an ever-growing field with endless potential. Print-in-place parts are a great example of this, providing novice and experienced users with the chance to make complete parts without having to do any assembly work. Of course, though, they also present a design challenge that will broaden your skills.