Despite all the plastic involved, what steps can you take to make 3D printing more eco-friendly? To begin with, the two areas you want to focus on are filament source and 3D printing power consumption.

To help you build an eco-friendlier future in 3D printing, we’ve compiled some of the most useful tips below.

Finding Your Filament

Choosing the right filament is the best place to start when making better decisions for the environment, but there is a lot of choice out there.

Here are some ways to narrow the choice down to the most eco-friendly option.

PLA Is the Way

Both PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) filament are common choices in 3D printing, but they have very different properties to consider.

On the one hand, ABS is made from petroleum. It's an oil-based plastic that cannot be recycled and will take years, if not longer, to degrade. On the other hand, PLA is produced from corn products and is both biodegradable and recyclable.

Luckily, PLA is leading the way in 3D printing and is a good choice for first-time printers because it doesn’t warp to the same degree as ABS does.

It does have its downsides, however. PLA material tends to be more brittle, leading to 3D prints that might break instead of bend. In contrast, ABS filament is a lot stronger and can be used to produce objects that need strength and durability.

Out of the two filaments, it’s clear that PLA is the way to go if we hope to reduce plastic pollution on earth.

Buy Recycled Filament

There are so many options when it comes to buying filament, including color, type, size, and weight, but did you know you also have the option of buying filament made from recycled material?

Recycled filament is made from scraps of plastic, plastic bottles, and even 3D printed waste from projects that went wrong. This scrap plastic is ground into a powder or made into pellets and put through a special machine that turns it back into usable filament.

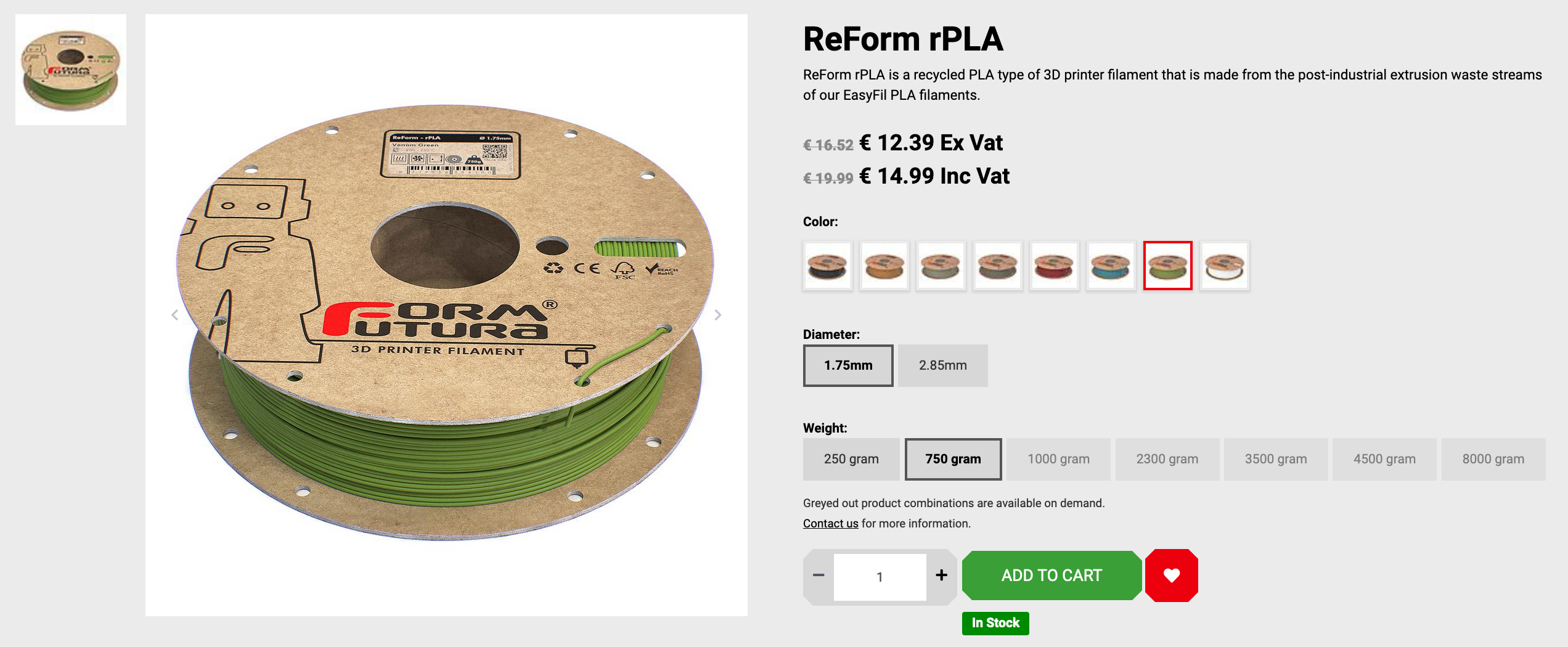

FormFutura is one company that has released a line of filament made from recycled materials, called ReForm, and it’s a great step towards an eco-friendlier future.

When searching for filament, the listing should note whether the filament is recycled, sometimes indicating the exact percentage of recycled material used in the product.

Some companies which are dedicated to reducing the impact of 3D printing materials on the planet also ship their filament on a cardboard spool or use recyclable shipping materials.

Make Your Own Filament

Aside from buying recycled filament, how about taking matters into your own hands and recycling it yourself?

This may not be the best option for a beginner hobbyist, but if you see 3D printing becoming a life-long passion then you might want to try making your own filament.

The way it works is fairly simple and the two most important machines required are a shredder and extruder.

The shredder machine will break down plastic waste, failed prints, or old plastic bottles into small enough pieces to be used in an extruder. The extruder, similar to the one on your 3D printer, will melt the plastic waste and extrude the material into the spaghetti-like form that we know as 3D printer filament.

Filabot is one company at the forefront of this technology. Besides just how cool the machines look, the firm specializes solely in recycling plastic for 3D printing. The downside is their products are expensive, with the Filabot EX3 Filament Extruder alone costing $2,812.

It’s worth mentioning, however, as innovations like these will put the power of recycling 3D printing plastic waste directly into the hands of small businesses and passionate individuals, leading to a greener 3D printing industry.

Power Consumption

The second biggest consideration when 3D printing is how much power it takes to produce an object, especially when 3D printing can take anywhere from one hour to several days.

While 3D printers don’t consume more than a desktop computer does per hour, reducing power usage will be better on the environment and save you money too.

Avoid Power-Hungry Printers

Using a less-energy intensive printer will be a better option for the environment and there are several ways to determine the energy rating of your 3D printer.

You can work out the power rating by multiplying the voltage (V for volts) by the current (A for amps) to calculate the number of watts (W) your machine will output.

Often the power rating will also be included in the specifications of the 3D printer you are interested in and while not every print will use the same amount of power, it will give you an indication of what the maximum power consumption looks like.

In general, a larger printer or one that can print at higher temperatures will consume more power. But to really monitor your power output you can use a power measurement device to see directly what your 3D printer is consuming.

This is especially useful if you want to try different methods of conserving power, which we’ll look at next.

In general, knowing the power output of a 3D printer can help you compare devices before buying so that you can select a 3D printer that meets your needs but doesn’t consume unnecessary amounts of energy.

Power Output Comparison

The maximum power output of some of the best 3D printers we recommend:

|

3D Printer |

Power Output |

|---|---|

|

Ultimaker S5 |

350W |

|

Creality Ender 3 Pro |

270W |

|

Anycubic Photon Mono |

45W |

|

Dreamel DigiLab 3D45 |

552W |

|

Flashforge Adventurer 4 |

320W |

As you can see, the power differences between some of our recommended 3D printers can be quite large. In this list it ranges from 45W to 552W, making the power rating of a 3D printer a notable consideration when comparing models to buy.

How to Conserve Power

The first thing you can do to reduce your 3D printer’s power consumption is to use PLA filament.

Other filaments such as ABS and Nylon require a higher printing temperature, which leads to more power being consumed.

In addition to heating the nozzle to extrude the filament, your printer also needs to heat up the printing bed. While some people think that you don’t necessarily need a heated bed when using PLA filament, it is definitely necessary for ABS filament.

Contributing to the power consumption of heated beds will be its size and, again, the temperature of your print, which is another point in favor of PLA.

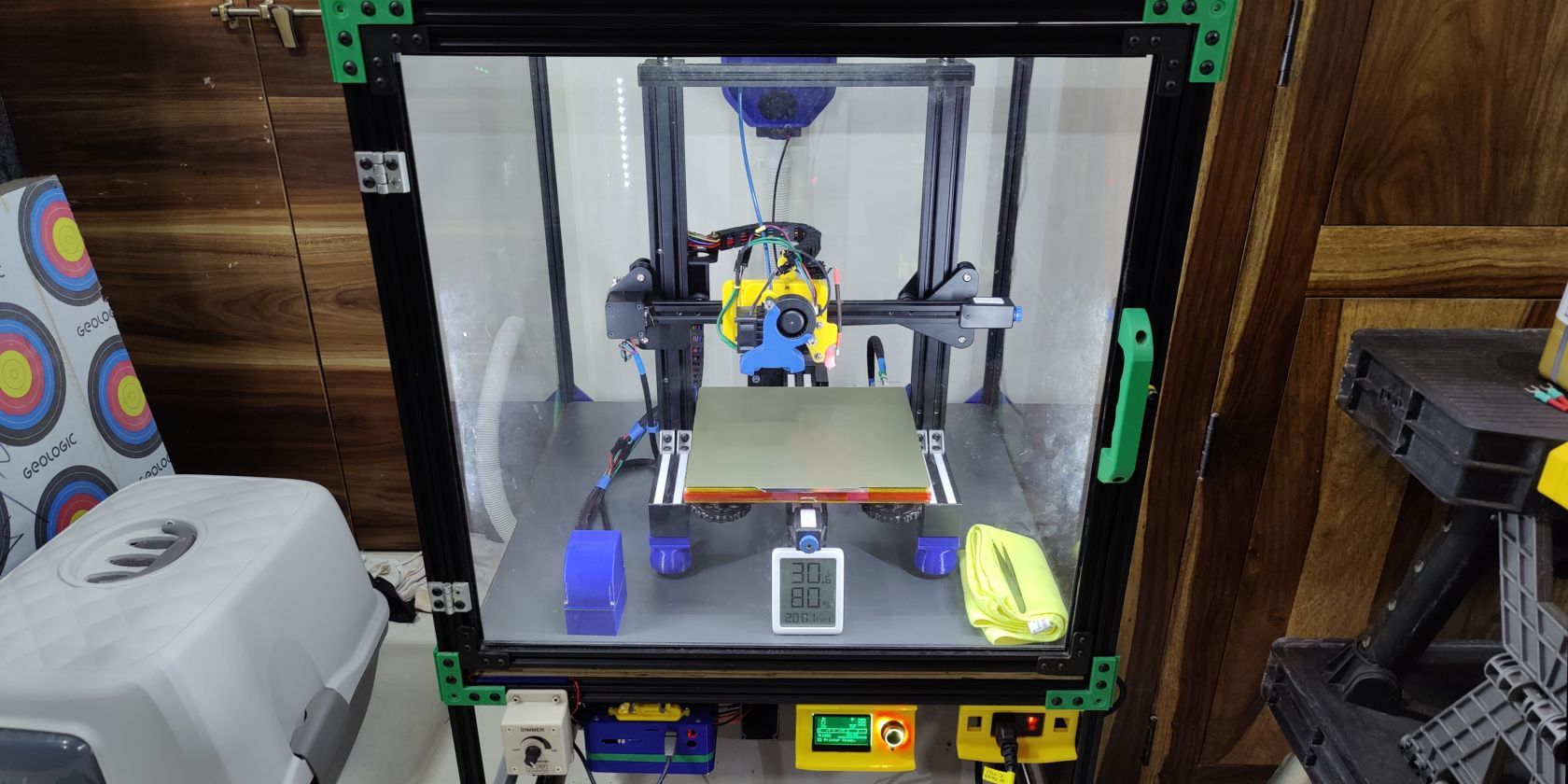

One way to prevent heat loss from your printer as it works to reach the set temperature is to have an enclosure around the printer to keep the heat from escaping. You can buy an enclosure separately; however, some 3D printers do come with their own.

Think Before You Print

As a final note, the best thing you can do to reduce the carbon footprint of your 3D printer is to not print without thinking it through first.

If your 3D printed object ends up in landfill, then none of the points above will really have mattered.

Think carefully about the life of your object: can you recycle it when you no longer want it? Could you give the object away? Will it biodegrade if it does end up in the rubbish?

With so many incredibly cool things to print from the comfort of your home, the most important thing to remember is to be responsible about what you do choose to print.

When you decide on an object worth printing, make sure to research thoroughly what the best print settings are. Some things to consider are best print temperature, recommended filament type, print thickness, and print supports.

Getting these settings right and calibrating your 3D printer’s extruder will help you print the object correctly the first time round, avoiding failed prints that will likely end up in the bin.

3D Printing for the Future

Choosing the biodegradable and recyclable option of PLA filament is a good choice to begin with. Even better, source your PLA from companies which are producing recycled filament on cardboard spools.

Power wise, read the power output of your 3D printer (watts) to compare the power consumption between models, conserve power by using PLA for lower print temperatures, and use a printer with an enclosure to prevent heat loss.

There is no question that 3D printing is a fantastic and empowering technology, but to make it a viable option for the future we have to make it more eco-friendly. Luckily, we can start doing that now.