Your CPU and GPU come with cooling fans, but they won't cool anything if the ambient temperature in your PC case is alarmingly high.

That's why you need case fans.

Custom PCs are typically built in modern cases that ship with only one lousy fan. This isn't the manufacturer pinching pennies but instead leaving the job of choosing the case fan configuration up to the user.

And getting that right is critical to ensure both optimal performance and long-term reliability of your custom PC. So, here's how you choose the best case fans for your PC.

Why a Single Case Fan Isn't Enough

The short answer is that a single case fan isn't nearly enough to prevent your computer from overheating.

PC case cooling, however, is a bit more complicated than that. The case manufacturer leaves this task to you because custom PCs not only exhibit wildly different component configurations, but the physical orientation of the cooling fans also varies from one build to another.

Computing performance is directly proportional to the number of watts you can push through the CPU and GPU. A vast majority of this power is dissipated as heat. Overall PC performance is severely limited if you can't take this heat away from the components efficiently.

That's a problem because a PC with a single case fan is functionally indistinguishable from an oven.

Therefore, choosing the right case fan configuration for your shiny gaming or video editing rig has a significant impact on the thermal headroom available. A PC that runs cool allows the CPU and GPU to attain higher turbo clock speeds while also sustaining them for longer.

That's a free performance upgrade without venturing into the world of overclocking.

How Does a Case Fan Work?

Knowing the basic construction of a typical PC case fan makes it easy to understand specifications and determine which ones are ideal for your use case. Computer fans use either an axial or centrifugal design. Axial fans intake and exhaust air along the blades' rotational axis, whereas centrifugal fans exhaust air perpendicular to the axis of rotation.

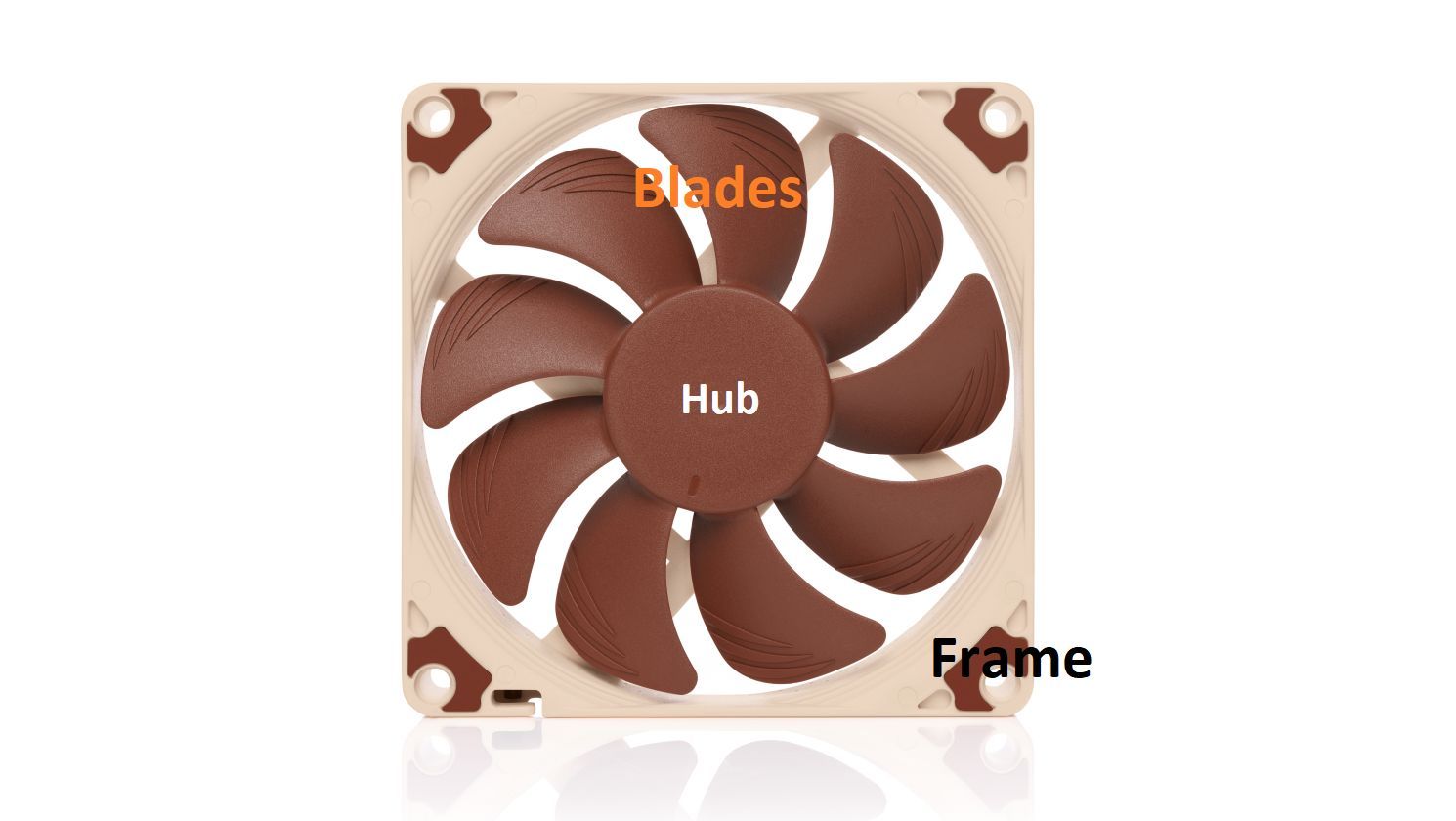

Because desktop computers exclusively employ axial fans, we won't bother with the other kind. A typical axial fan is comprised of three main parts—the hub, blades, and frame. The blade and frame are simple plastic parts, but the hub houses the most expensive and important components, such as the motor, bearings, and electronics.

An axial fan generates airflow by driving the motor to spin the blades at high speeds. The volume of airflow generated depends on motor speed/torque, the blades' aerodynamic efficiency, and multiple other factors.

If you're in the market for a case fan, you ought to know how these components dictate their cost and quality.

The 5 Most Important Case Fan Specifications

Let's take a look at the various specifications governing fan performance.

1. Airflow and Static Pressure Optimization

Fan performance is determined by two mutually exclusive metrics of airflow and static pressure. The former measures the amount of air moved by a fan in a given time, usually expressed in cubic feet per minute (CFM). Higher the airflow of a fan, the greater the volume of air it can move, which positively impacts cooling performance.

A higher airflow fan is ideal when you're exhausting hot air out of the case. The path taken by the air when exiting the case is entirely free of obstructions in this configuration. Now imagine the same fan employed to push cold air through a liquid-cooled radiator. The thick radiator with its dense fin structure presents a significant amount of resistance to airflow.

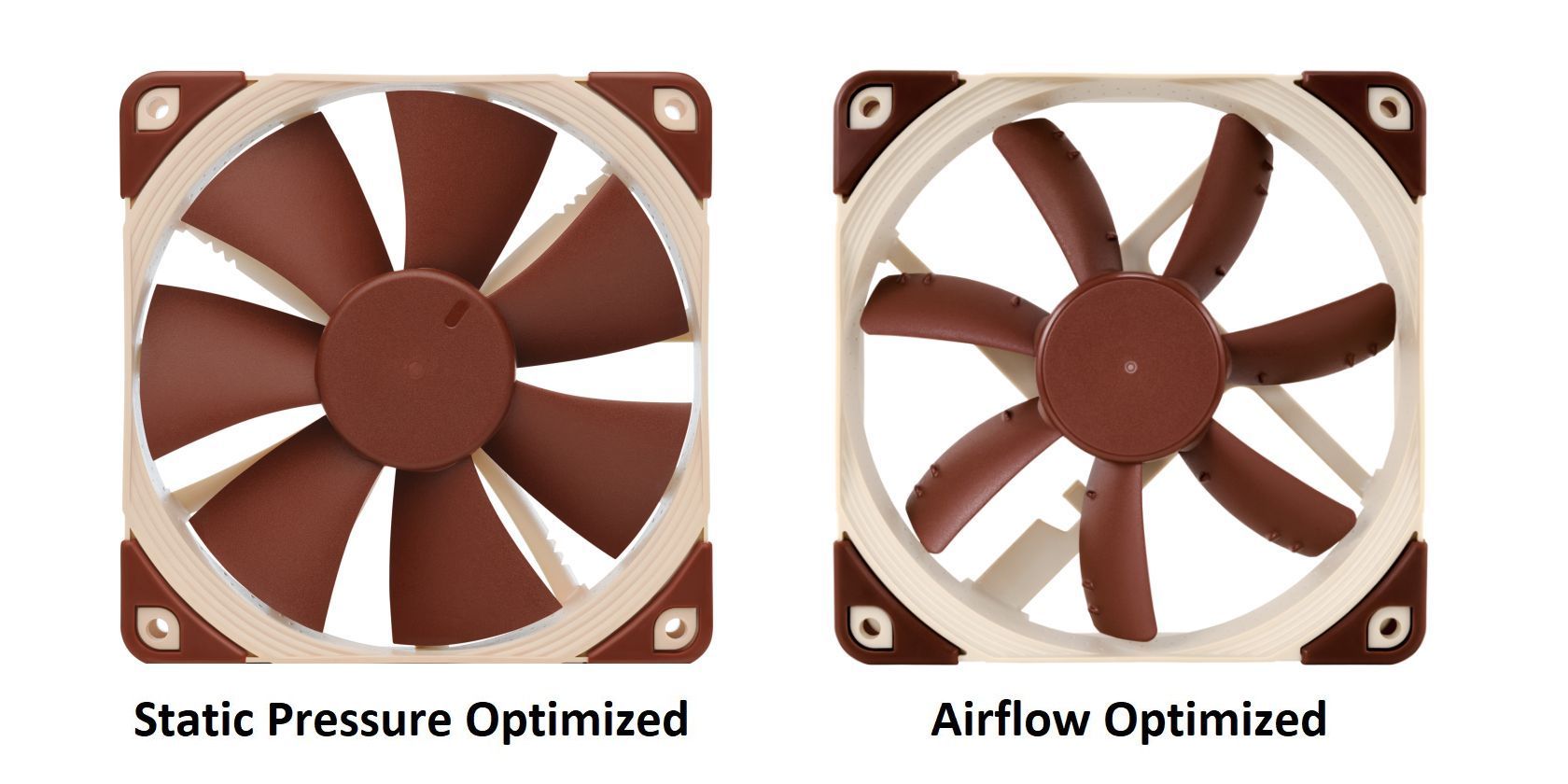

The same high-airflow fan severely underperforms in this role because the restrictive radiator mesh requires a fan generating higher static pressure to push air through it. Such fans have specialized blade geometries designed to sacrifice airflow to improve static pressure, measured in Pascals (pa) or millimeters of water (mm H2O).

By their nature, static pressure optimized fans are better served as intake fans in restrictive cases with higher internal component density typically seen in small form factor builds such as mini-ITX PCs. These fans are ideal for pushing air through thick radiators and CPU air coolers with dense fin stacks.

2. Fan Size

The size of an axial fan is expressed in millimeters and is roughly equal to the length of the frame or the diameter of the fan blades. It affects the amount of air pushed by a fan, which in turn depends on two primary factors—the surface area of the blades and the rate at which they spin.

Larger fans should technically generate more airflow due to the greater surface area of the blades, but the additional weight and aerodynamic drag also increase current draw and power consumption. That's why larger fans are designed to spin slower to deliver roughly the same amount of airflow as a smaller fan at similar levels of power consumption.

Because most PC case fans are designed to maximize the power draw from a standard motherboard fan header, irrespective of their physical size, the total wattage remains more or less constant across the fan size spectrum. Not surprisingly, a typical 200mm fan spins at a maximum of 800 RPM to deliver nearly the same amount of airflow as a 120mm fan operating at its 2000 RPM limit.

As a rule of thumb, larger fans tend to be quieter than their smaller cousins, thanks to lower rotational speeds. You can find specialty fans operating at higher speeds, but these draw more power and require dedicated fan controllers with beefier power delivery.

3. Fan Thickness

Also expressed in millimeters, fan thickness is the second set of numbers expressed alongside the fan size. In the desktop PC space, fan thickness typically ranges from 10mm to 40mm. A thicker fan will deliver increased airflow compared to its thinner counterpart of the same size for several reasons.

Thicker fans make it possible to design blades with a steeper angle of attack, which allows them to scoop up a larger amount of air per rotation. The greater depth not only increases the surface area of the blade, but the thickened frame also improves the fan's inherent suction effect, which manifests as higher static pressure.

4. Bearing Types

The type of bearing used in a case fan determines its cost, lifespan, and operating noise.

The cheapest fans use sleeve bearings, which involve a steel shaft rotating inside a softer brass sleeve. These bearings are quieter when you first use them but become noisier with time. They also tend to fail sooner and more abruptly. Sleeve bearing fans can only be used in the vertical orientation. Mounting them horizontally in the top or bottom orientation leads to premature failure.

Double ball bearing fans use traditional ball bearings along the front and rear ends of the shaft. This design reduces friction significantly to prolong life and allows the fan to be used in any orientation. The only downside here is the slightly increased noise level compared to sleeve bearings. Their single bearing variants use a sleeve bearing for the other end of the shaft and aren't as reliable as the double ball bearing variety.

Fluid dynamic bearing combines the reliability of ball bearing design with the low noise of sleeve bearing technology. It's essentially a modified sleeve bearing with grooves cut in a herringbone pattern to force lubricant efficiently across the rotating surfaces. The design combines the fan's inherent rotational forces and the hydrostatic effect of the lubricant to create a pressure field that stabilizes the moving parts and eliminates friction. Such fans last the longest while supporting all orientations. The only downside is their high price.

However, fluid dynamic bearings aren't the only hybrid designs based on sleeve bearings. Sunon's Maglev and Noctua's SSO bearings also improve the design by incorporating magnets to stabilize and reduce friction. Both bearings are renowned for their long life and low noise levels.

5. PWM and Voltage-based Fan Speed Control

Intelligent microprocessor-based speed control is a major benefit of hooking fans up to powerful PC motherboards. Unlike regular DC fans that use only two wires—one for VCC (power) and another for ground—the simplest PC case fans have an additional wire for the tachometer signal, which relays the fan's rotational speed using an onboard Hall-effect sensor.

These three-pin case fans allow the computer to sense the fan speed and modulate it to strike a healthy balance between cooling and quiet operation. The fan speed is modulated by varying the voltage in such designs. While this works fine at higher speeds, reducing voltage significantly to attain lower fan speeds affects performance negatively.

More expensive fans work around this problem by adding an additional wire for PWM (Pulse Width Modulation) signal. Such fans maintain a constant voltage, but the speed is varied by rapidly switching the fan on and off several times a second using high-frequency switching circuitry. The added complexity and components obviously come at a higher cost.

Optimal Fan Orientation

Now that we have figured out how to pick the right fans, here are some pointers on correct fan placement within the case. The most basic rule to remember is to make sure you direct airflow across the case from one point to another.

The direction doesn't matter. You can intake air from the rear of the case and exhaust it at the front, and it will work as long as you don't mind a face full of hot air while gaming. The only exception exists when air is being channeled vertically. Hot air rises naturally, so there's no point fighting the natural process of convection.

However, what doesn't work is forcing fans on the opposite sides of the case to work against each other. This isn't as bad for exhaust fans, but if you put two intake fans at the opposite ends of the case, the opposing air currents will clash. The ensuing turbulent flow generated will cause the hot air to be trapped and recirculated within the case.

As explained earlier, use static-pressure optimized fans to push or pull air through a radiator. If your case isn't well ventilated (glass or solid front) or is otherwise small and/or crowded inside, you are better off using static-pressure optimized fans for the air intake points. Easy breathing cases with mesh front shrouds can get away with airflow-optimized fans for intake, but that's rarely optimal unless you have enough exhaust fans.

Air Pressure Optimization

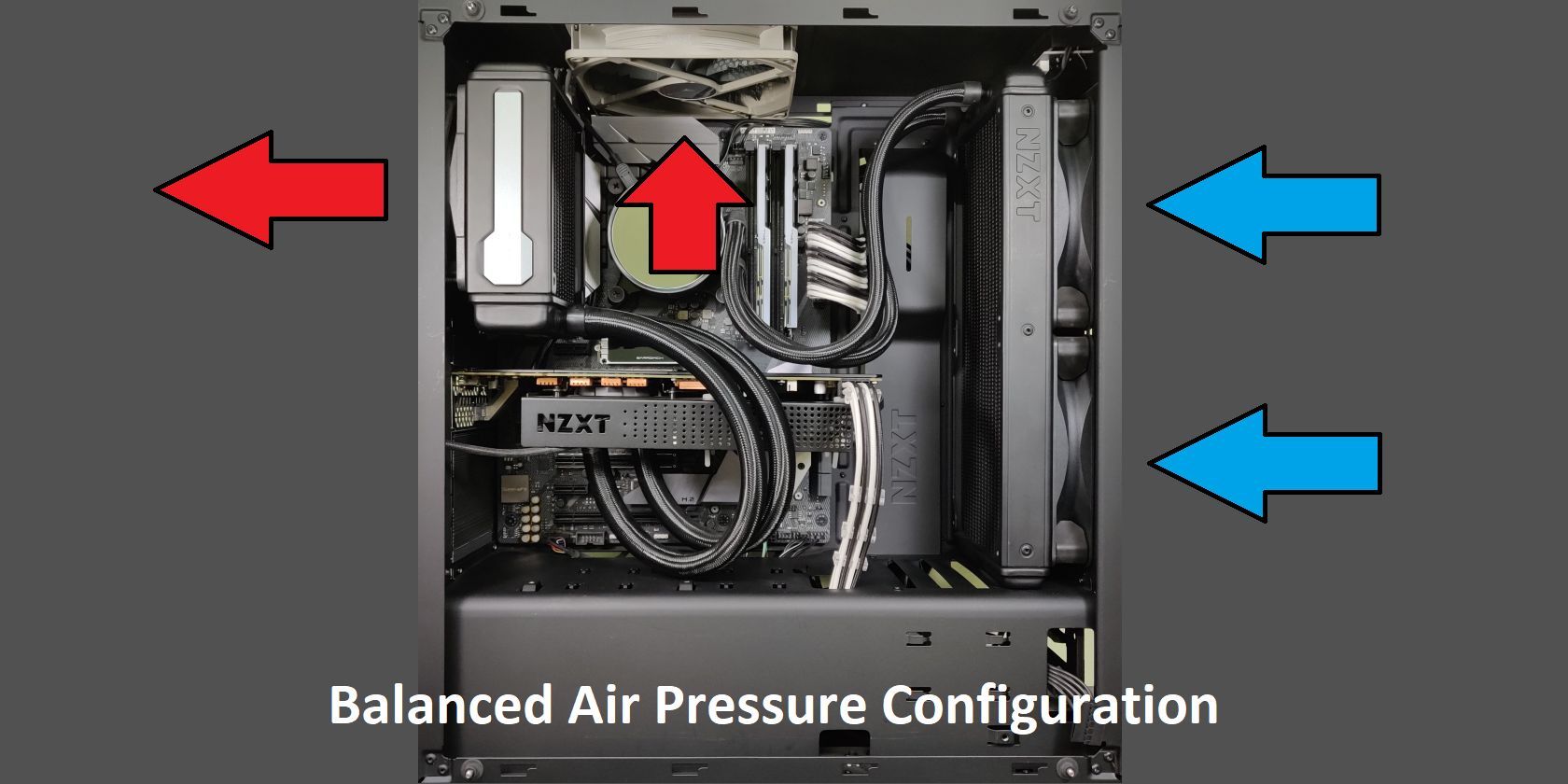

We recommend using at least three case fans, with more required for high-stress applications. How many of those you use for exhaust and intake determines whether your case has a positive or negative air pressure configuration.

A case using more intake fans than exhaust fans will experience positive internal air pressure simply because more air is being pushed in than it is being taken out. The excess air pressure results in air being pushed out of every nook and cranny, which creates a natural barrier against dust. This is highly a desirable trait.

However, achieving a positive pressure setup isn't always feasible. You are better off focusing on drawing heat out of cases with poor ventilation. This necessitates more exhaust fans, which results in a negative pressure setup. Although this will attract more dust, it sure beats overheated components.

Just don't go overboard with negative or positive pressure optimization. You ideally want to balance the number of intake fans with a slight bias towards intake to maintain positive pressure. At the end of the day, it is more important to establish streamlined airflow within the case.

How to Choose the Best Case Fans For Your Custom PC

Choosing PC case fans can feel overwhelming. There's a lot of information to consider, no doubt about it. Just remember that keeping the cool air flowing in one direction is the most important thing, and you won't get much else wrong.