The success of a 3D print depends on the integrity of the first layer. But just a bit of plastic oozing out of the nozzle can ruin everything. Not everyone can afford a printer equipped with servo-assisted nozzle wipe routines to get around this problem, but you can still spare a few minutes to manually babysit the first layer.

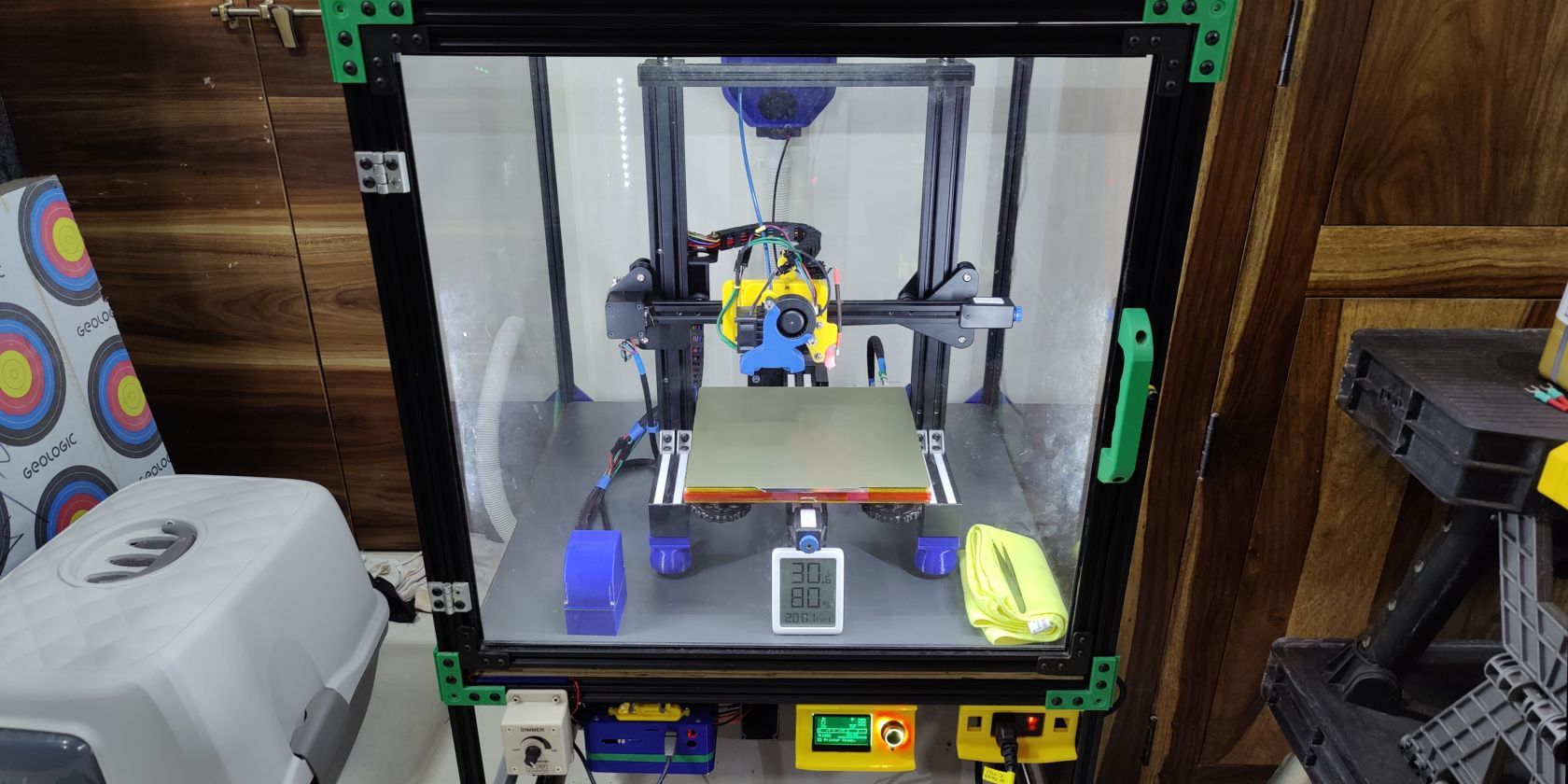

Good lighting, however, is the bare minimum requirement for that purpose. And incorporating it in your existing 3D printer is cheaper and easier than you think. Here’s how you can upgrade your printer with slick LED lighting to improve first-layer visibility.

Tools and Materials Required

In addition to a 3D printer, you will have to make sure you have these tools and materials ready before diving into this project. Since this guide offers options in terms of skills, tools, and materials required, the requirements are split into the mandatory and optional categories.

Most of the items listed are commonly found in a typical household, but you may need to purchase some of these. Although you can buy the mandatory items right away, please read through the guide once to figure out which one of the optional items you already have and make a note of those that you may need to procure.

Nothing is as frustrating as finding out you have a critical tool or component missing in the middle of a build.

Items You Absolutely Need

- 3D printer.

- SMD LED strip.

- Scissors.

- 3D printing filament (PLA, PETG, or ABS).

- Hookup wire (gauge varies according to voltage chosen).

- Wire stripper (recommended) or sharp blade.

- M3 T-slot nut (drop-in type recommended).

- 6mm M3 button head cap screw and compatible screwdriver.

Optional Items

- Phillips head screwdriver (standard sizes: #1 or #2).

- Solderless LED strip-to-wire connectors.

- Soldering kit.

- Heat-shrink tubing (10mm).

- Heat gun or lighter.

- Ring or fork insulated terminals.

- Insulated terminal crimping tool.

Step 1: Figuring Out LED Strip Placement

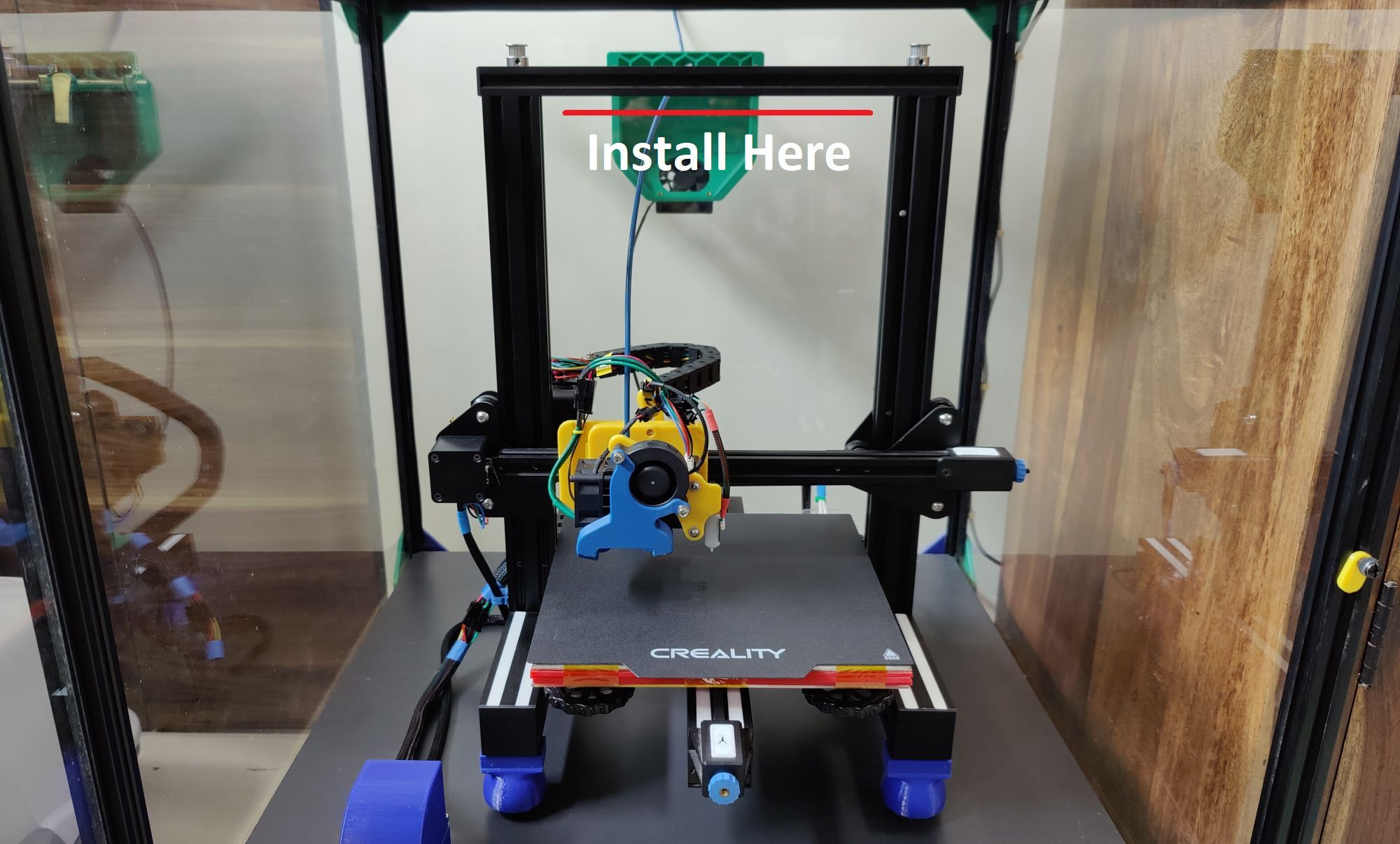

For the majority of 3D printers sporting the Prusa/Mendel bed-flinger design, such as the Prusa i3 or Creality Ender 3, there’s only one optimal location where you can install the LED strips. And that’s on the underside of the aluminum extrusion acting as the cross-member between the pair of Z-axis extrusions.

Installing the LED strip in this location will not interfere with your 3D printer’s motion system, while shining light directly down onto the build surface. The vertical Z-axis extrusions also serve as a convenient means to route any wires safely without fouling with the motion components such as linear rails or V-slot wheels.

Step 2: Download and Print the LED Strip Holder

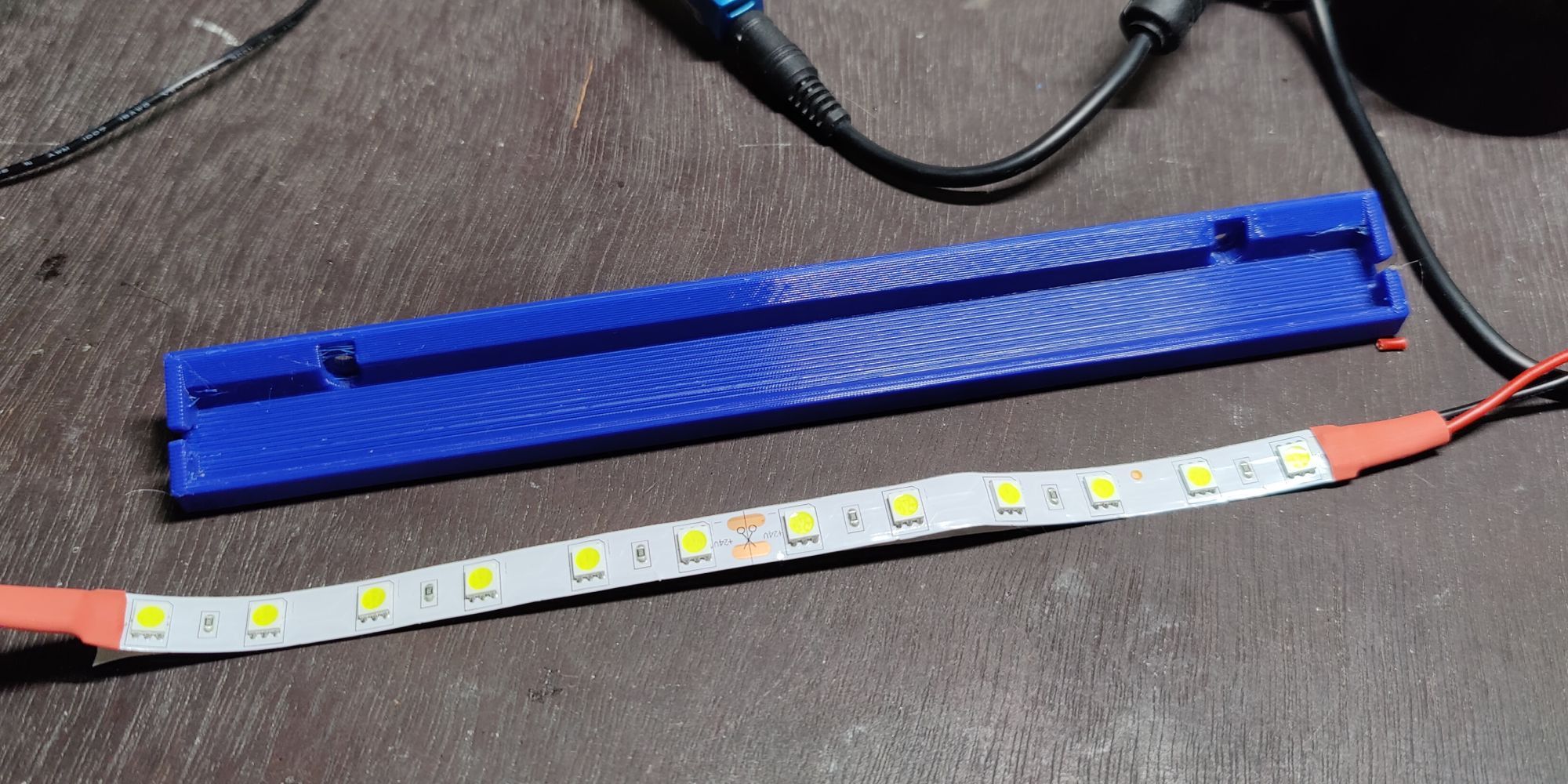

Using the adhesive backing on the LED strip to attach it anywhere on the printer is a risky proposition. Adhesives may fail over time, which can cause the LED strip come loose and fall into the motion components. That’s a recipe for electrical shorts and subsequent fires.

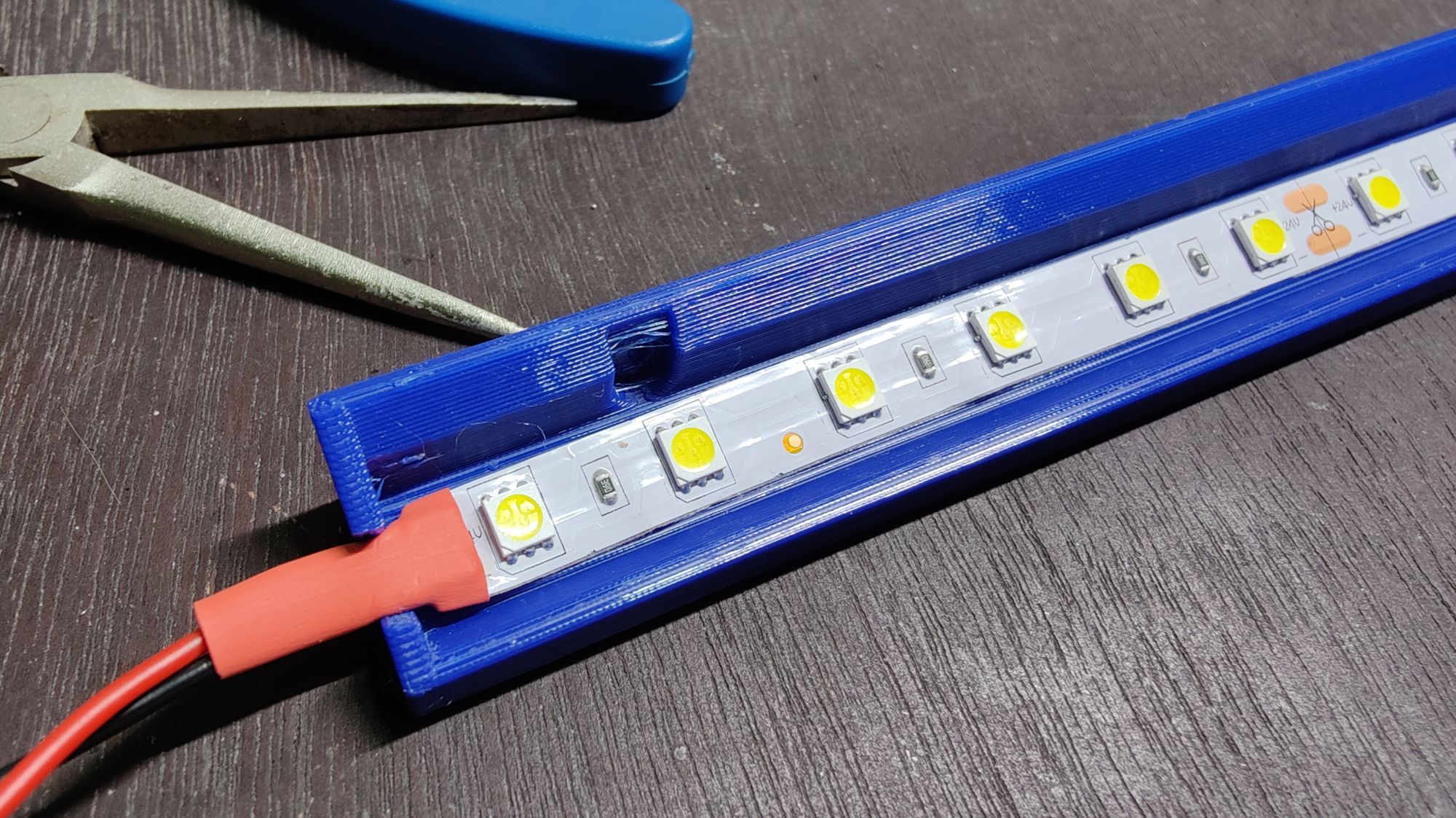

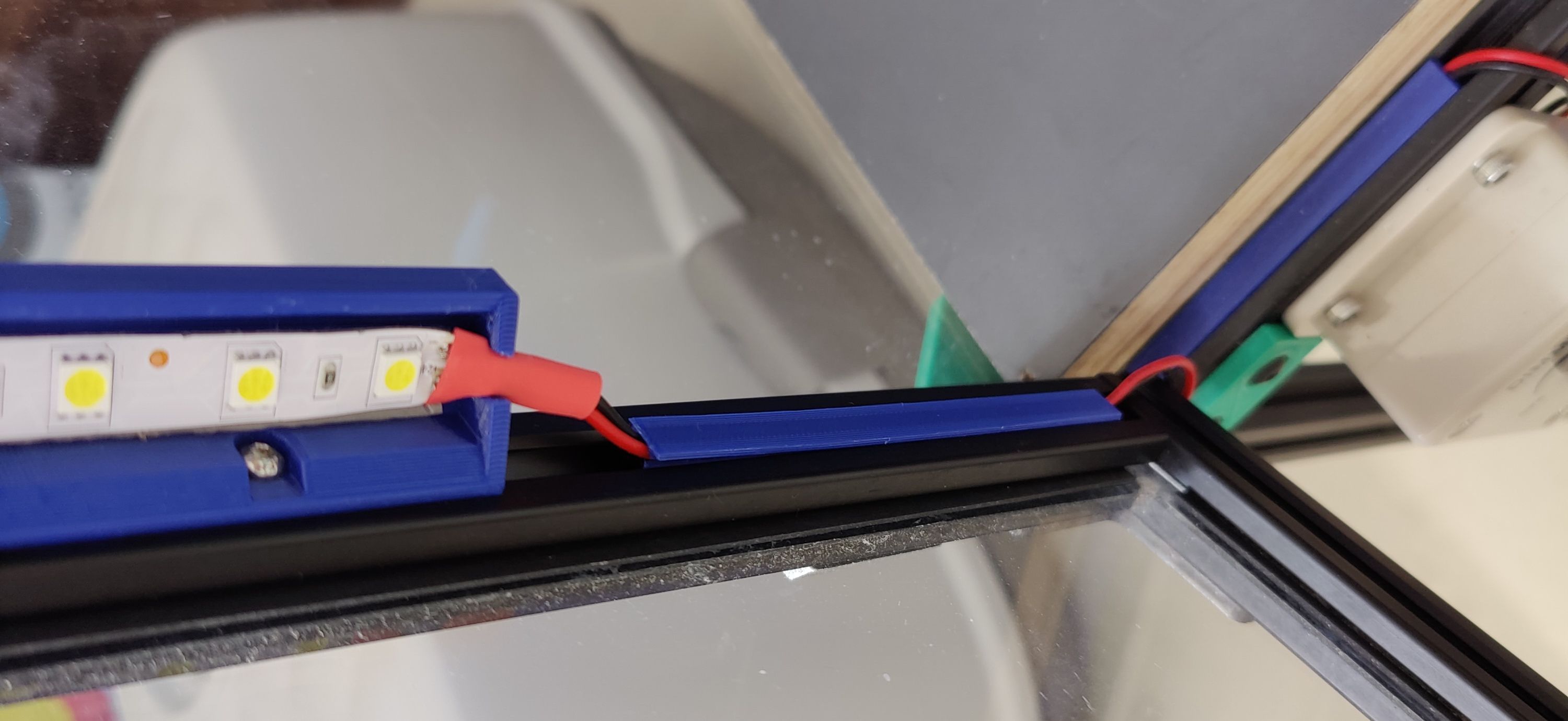

It’s safer to download and print an LED strip holder for Creality Ender 3, Prusa i3, Voron, or any other printers off free 3D model repositories such as Thingiverse or Thangs. You might also want to 3D print cable covers to organize cables out of the way.

It’s possible to increase or decrease the length of these cable covers in the slicer software to fit the exact dimensions of your printer.

Step 3: Choosing the Right LED Strip Type

SMD LED strips are available in a wide array of options, but getting the voltage rating right is of the utmost importance. The LED strips are typically available in 5V, 12V, and 24V options, with the choice depending on the operating DC voltage output supplied by your 3D printer’s power supply unit (PSU).

There are a couple of ways to ascertain the DC voltage supplied by the PSU. You can either get the information off the product page on the printer manufacturer’s website, or you can refer to the manual. In the worst-case scenario, you can physically check the compliance label on the PSU to figure out the DC output voltage.

SMD LED strips are also available in various color configurations. Single-color cold or warm white LEDs (bearing positive and negative terminals) are ideal for the purpose of illumination over RGB LED strips. You can also opt for high-density LED strips packing in more LEDs per meter for brighter illumination at the cost of higher power consumption.

Step 4: Wire Sizing Calculation

The thickness of the wire used to power the LED strips is directly proportional to the maximum current drawn. It is fine to use thicker wires than needed, but thinner wires tend to overheat and cause voltage drops.

Calculating the maximum current drawn by the LEDs is a good way to optimize wire thickness. This is done by dividing the power rating of the LED strip by its operating voltage. For example, if the LED strip is rated at 24 watts per meter and you are using half a meter, the power consumption of your LED strip is 12 watts.

For 24V LED strips, the maximum current drawn would come out at 0.5 amp. At half the voltage, 12V LEDs require twice the current, which works out at 1 amp. Finally, 5V LED strips would require a substantial 2.4 amps. This handy JST DC wire-sizing chart should help you choose optimal wire size for your particular LED strip.

Step 5: Cut the LED Strip to Size

Cut the LED strip to size as per the fitting requirements of the 3D-printed holder of your choosing. Be sure to cut the LED strip only where exposed copper pads/terminals are visible. This is marked with a scissor icon on most LED strips.

Step 6: Prepare the Hookup Wires

The length of the wire should be sufficient to bridge the gap between your 3D printer PSU and the LED strip. It’s safer to keep a margin of error and oversize the wire. You can always cut it down to size later.

Using either dedicated wire strippers or a sharp blade, expose about an eighth of an inch of the red and black hookup wires.

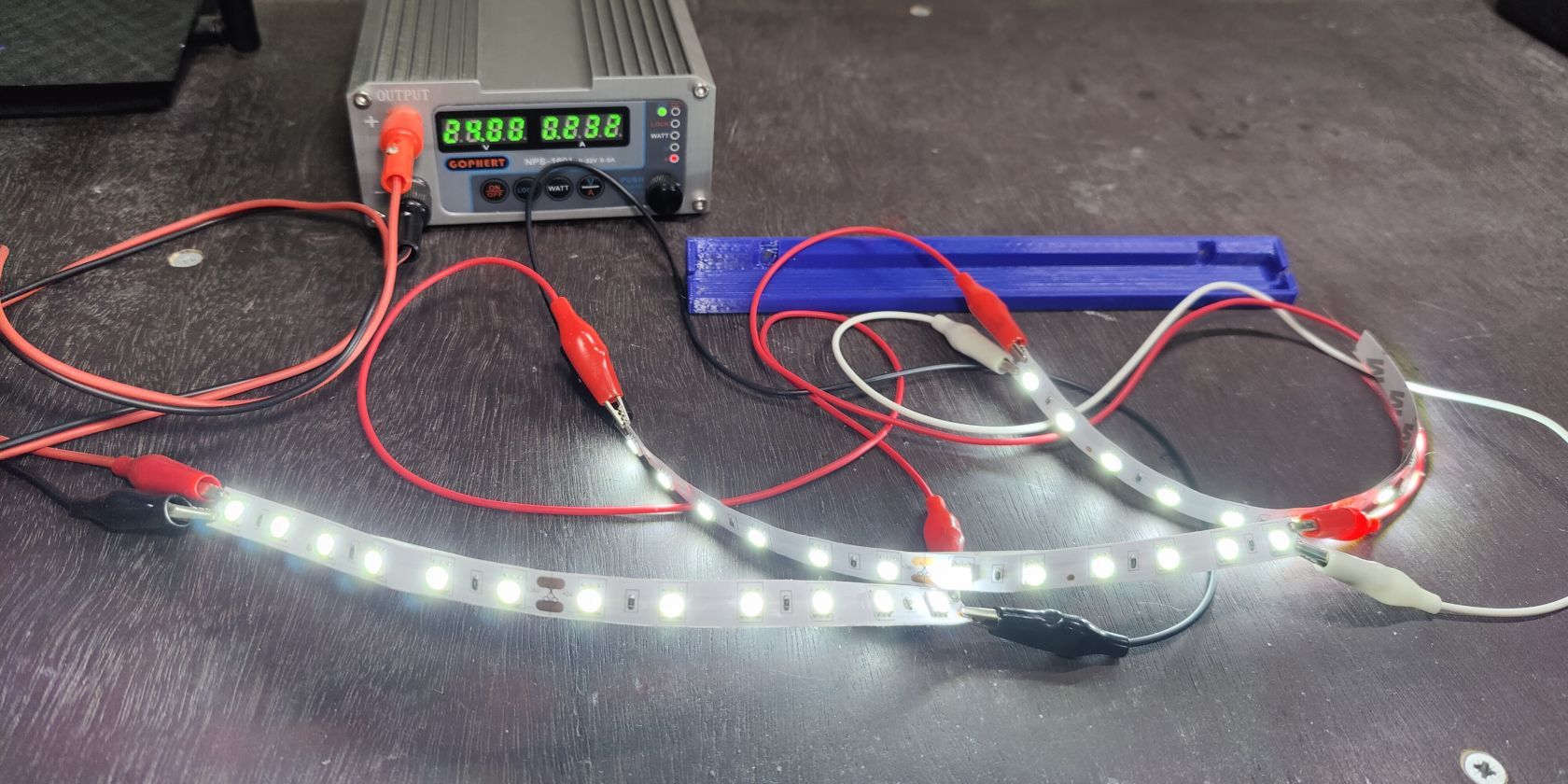

Step 7: Wire Up the LED Strip

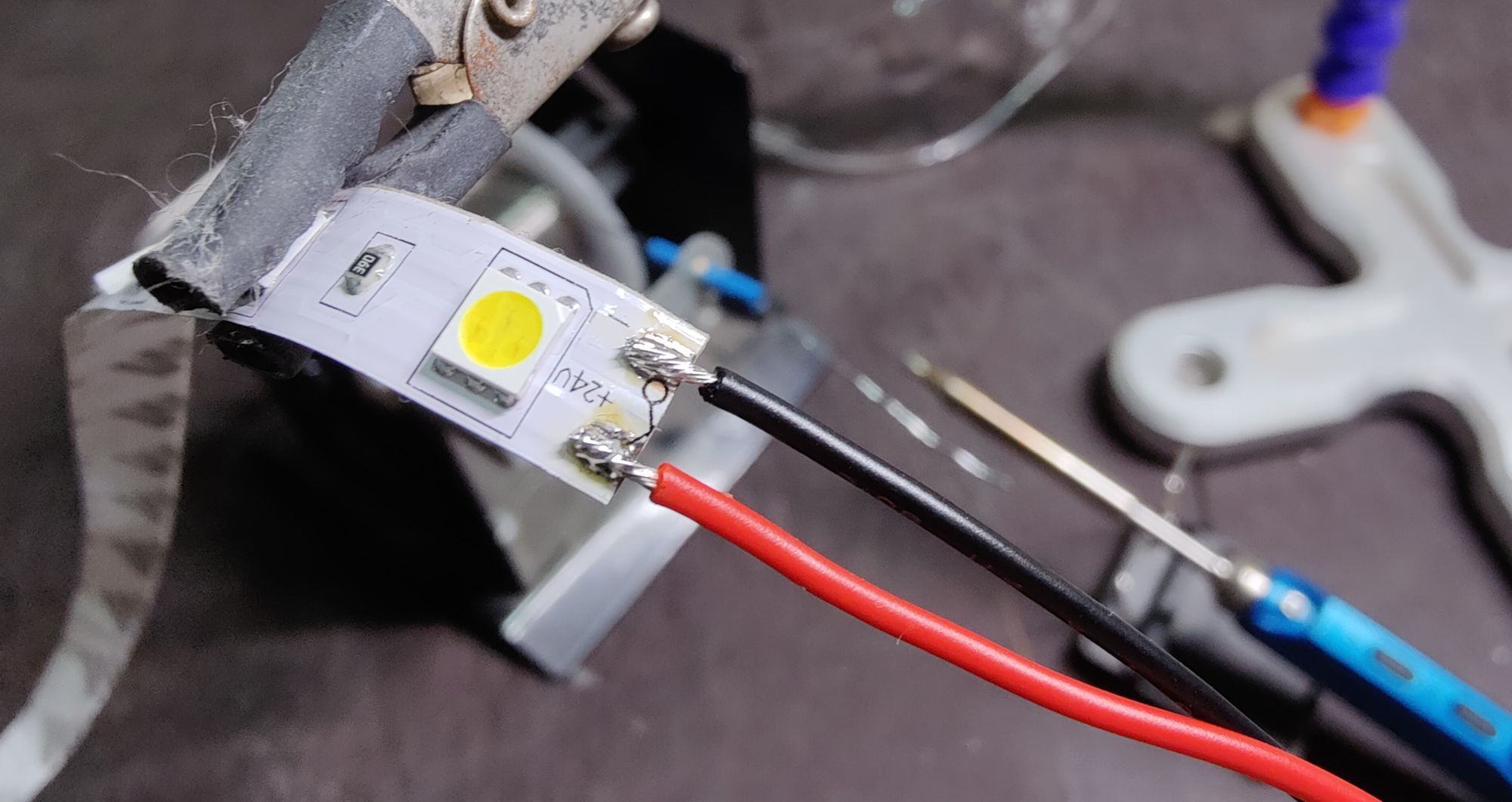

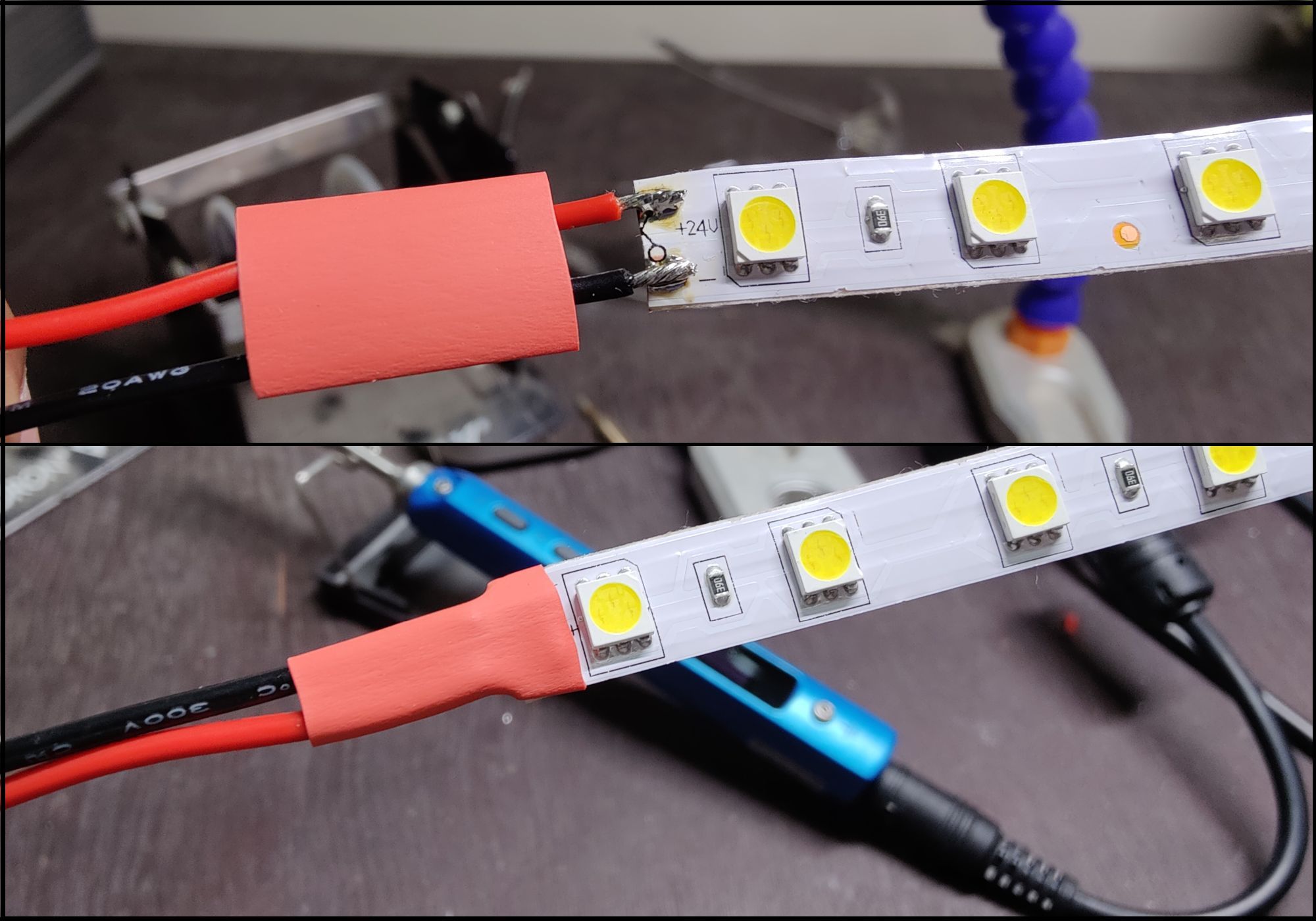

If you know your way around a soldering iron, proceed to solder the red and black wires to the positive and negative terminals, respectively, on the LED strip. Top that off by using either a lighter or heat gun to insulate the exposed solder joints with heat-shrink tubing.

If soldering isn’t your cup of tea, solderless LED strip-to-wire connectors allow you to do the same without requiring any tools. Just be sure to get the polarity of the wiring right. The red wire goes to the positive terminal and black to negative.

Step 8: Install LED Strip in 3D-Printed Housing

LED strips usually come with adhesive backing. Use that to fix the LED strip in the 3D-printed holder.

Now would be a good time to ensure that your 3D printer is powered off and disconnected from the power outlet. Remove the mains cable from the power inlet socket on the printer to be absolutely sure.

Step 9: Mount Housing to 3D Printer

Unless you fancy taking your 3D printer apart, it is recommended to use drop-in M3 T-slot nuts to install the LED strip assembly onto the printer. Depending on the type of T-slot nuts chosen, they can either be dropped straight into the aluminum extrusion, or dropped and then turned clockwise to lock them in place.

Once the T-slot nuts are in place, align the corresponding holes on the LED strip holder and secure them into the T-slot nuts using M3 button-head cap screws.

Step 10: Crimp Remaining Ends of Wires

Use the wire strippers to expose the remaining free ends of the red and black wires. The insulated terminal crimping tool will come in handy to crimp either ring or fork terminals onto the wires.

Although it is tempting to shove the stranded wires into the screw terminals without crimping insulated terminals onto their ends, doing so introduces the risk of loose connections and shorting.

Step 11: Connect LED Strip to PSU

Refer to your 3D printer’s manual to locate the PSU and expose the terminal block. It bears screw terminals for AC input and DC output. The AC input terminals (marked by symbols L, N, and G) should already be populated with the mains input wires. These shouldn’t be tinkered with at any cost.

The DC side of the terminal blocks is marked by + and - symbols signifying the positive and negative terminals. Hook up the red wire to the positive terminal and the black wire to the negative terminal. Reinstall the PSU in its correct place.

Step 12: Cable Management

Route the wires into the aluminum extrusion channels in such a way that they don’t interfere with the V-slot wheels, linear rails, or any other motion system components. Use the 3D-printed cable covers to secure the wiring into place.

Move all printer axes from end to end a few times to ensure that everything moves freely without hitting the LED strip, wires, or the cable covers.

Do a Test Run

With one hand on the power switch, and ready to kill the mains power supply at a moment’s notice, switch on the 3D printer. Your LED strip should light up the build surface if everything went according to plan.

Add LED Lights to Your 3D Printer: Success!

By following the step-by-step instructions, you will have now added an LED strip to your 3D printer to light up the build surface so you can achieve a perfect first layer.