Anycubic Photon Ultra

With the release of the Photon Ultra, Anycubic has introduced an enticing alternative to monochrome LCD screen printers. As a DLP resin printer, users can expect a long-lasting, money-saving exploration into resin printing with even more precise detailing for their prints. While the Photon Ultra does have some rough edges, its long-term savings and quality prints go a long way to make resin printing even more inviting.

- DLP projector light uniformity of up to 90%

- Printing speed of 1.5s per layer / Max of 60mm per hour

- Projector-based DLP technology

- Brand : Anycubic

- XY Resolution: 0.08 mm / 720p (1280 x 720 px)

- Build area: 102.4 (L) x 57.6 (W) x 165 (H) mm

- Light Source: UV-LED (wavelength 405nm)

- Layer Thickness: 0.01-0.15mm

- Printer Size: 222 (L) x 227 (W) x 383 (H) mm

- 20,000+ hour operation life (no screen replacing)

- DLP precision

- Laser engraved build plate for better adhesion and print removal

- Quiet operation (no fan)

- Energy saving (12W)

- Relatively small build plate

- USB port issues

- DLP resin may require support adjustments

Anycubic Photon Ultra

With the release of the Photon Ultra, Anycubic has introduced an enticing alternative to monochrome LCD screens. As a DLP resin printer, users can expect a long-lasting, money-saving exploration into resin printing with even more precise detailing for their prints. While the Photon Ultra does have some rough edges, its long-term savings and quality prints go a long way to make resin printing even more inviting.

- DLP projector light uniformity of up to 90%

- Printing speed of 1.5s per layer / Max of 60mm per hour

- Screenless DLP technology

- Brand : Anycubic

- XY Resolution: 0.08 mm / 720p (1280 x 720 px)

- Build area: 102.4 (L) x 57.6 (W) x 165 (H) mm

- Light Source: UV-LED (wavelength 405nm)

- Layer Thickness: 0.01-0.15mm

- Printer Size: 222 (L) x 227 (W) x 383 (H) mm

- 20,000+ hour operation life (no screen replacing)

- DLP precision

- Laser engraved build plate for better adhesion and print removal

- Quiet operation (no fan)

- Energy saving (12W)

- Unreliable and problematic USB slot

- Relatively small build plate

- DLP resin can require self-supporting and/or support density increases

The Anycubic Photon Ultra aims to prove that you don't have to forgo quality for savings. With a long-lasting projector and DLP high resolution, those disenchanted with LCD screens finally have an alternative. Still with a 720p resolution, can the Photon Ultra's print quality challenge 4K and above resolution monochrome screens?

A Kickstarter DLP 3D Printer

As Anycubic is a major name in 3D printing, it might come as a surprise that the Photon Ultra was launched via Kickstarter. Furthermore, the Photon Ultra's pedigree includes Texas Instruments (TI) who co-engineered the Photon Ultra to deliver digital light processing (DLP) technology to a consumer-priced desktop resin 3D printer.

So those looking to purchase the Photon Ultra won't be able to immediately. For the purposes of this review, Anycubic has provided an early release model.

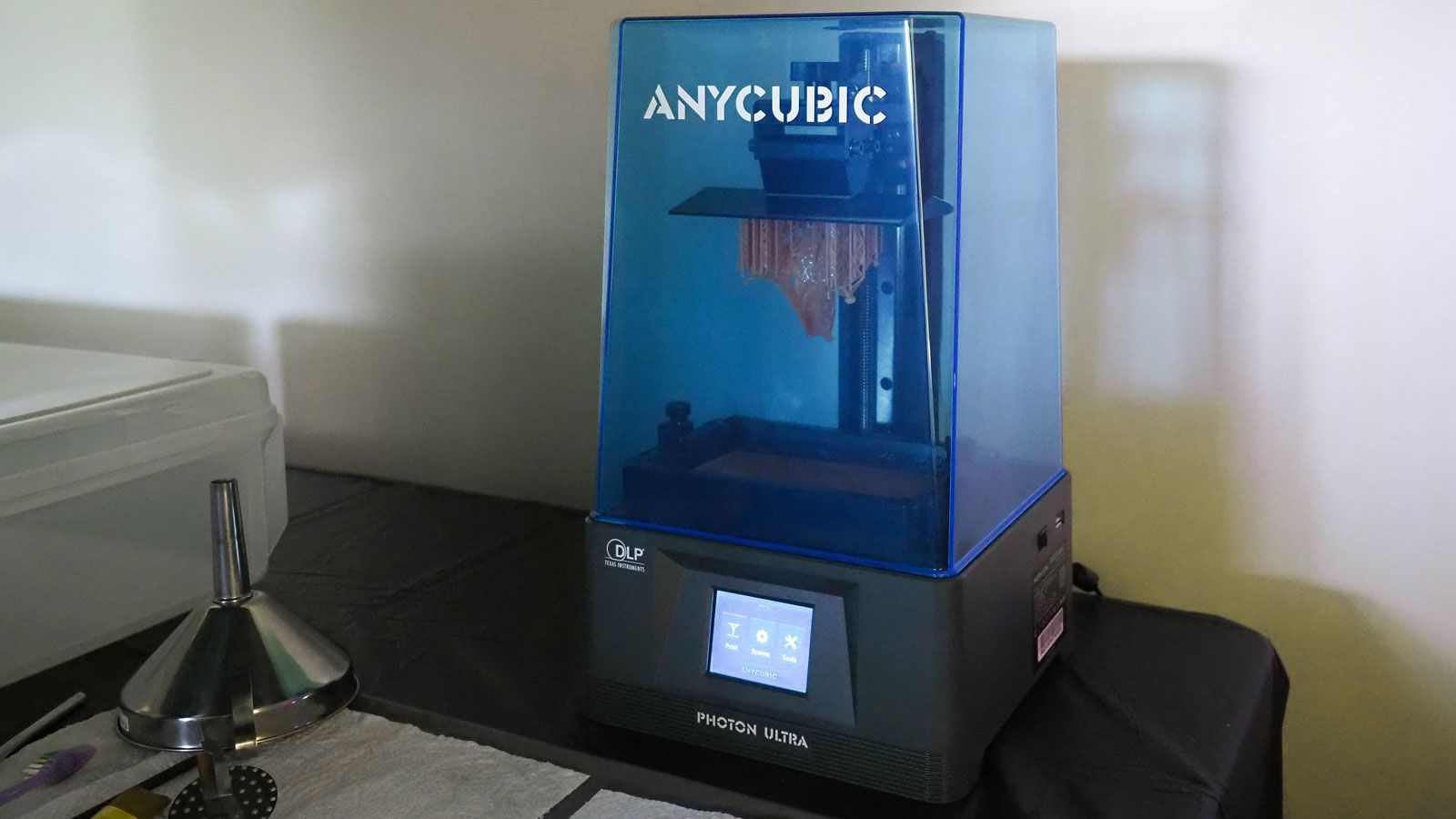

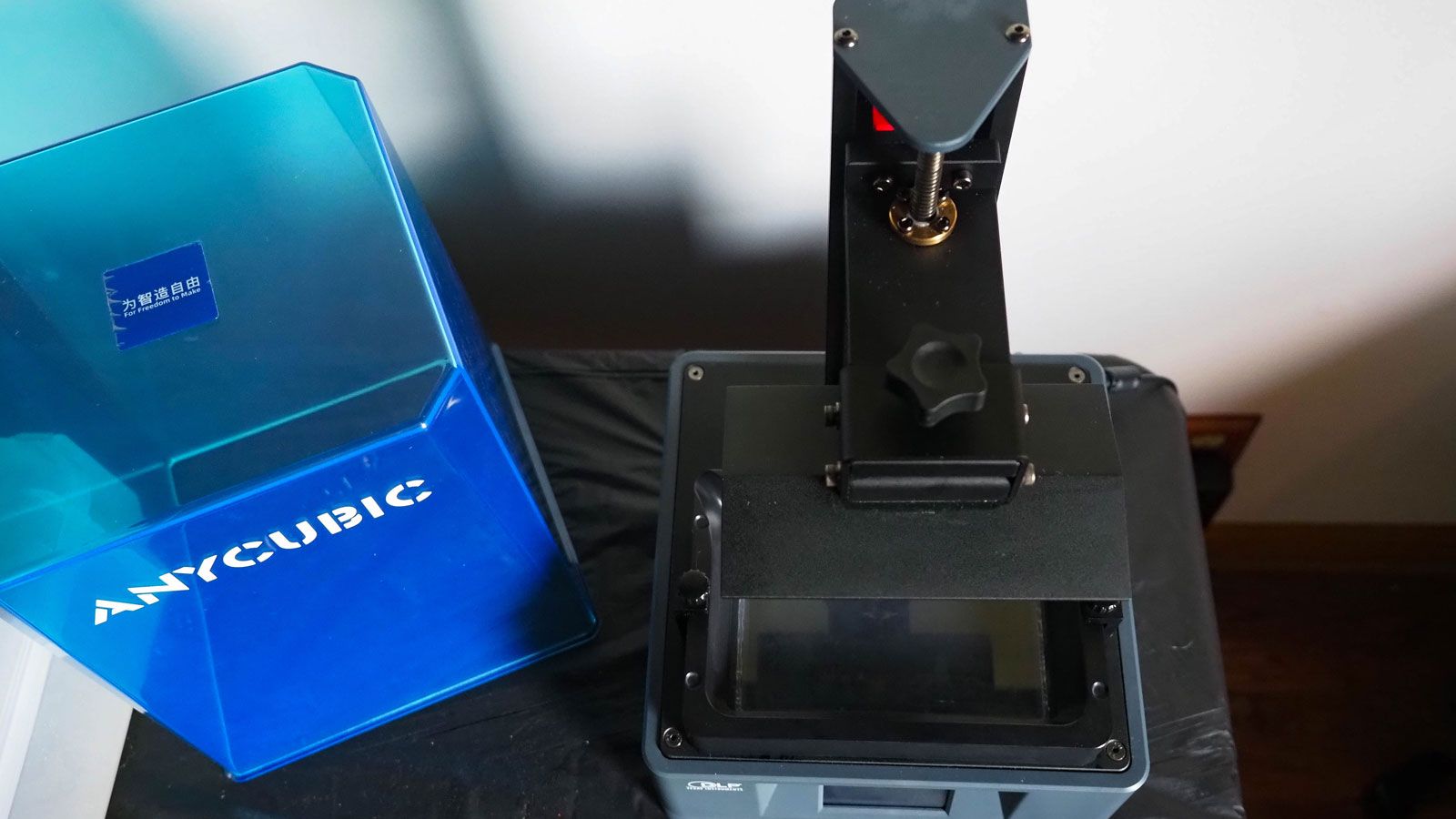

Anycubic Photon Ultra Design

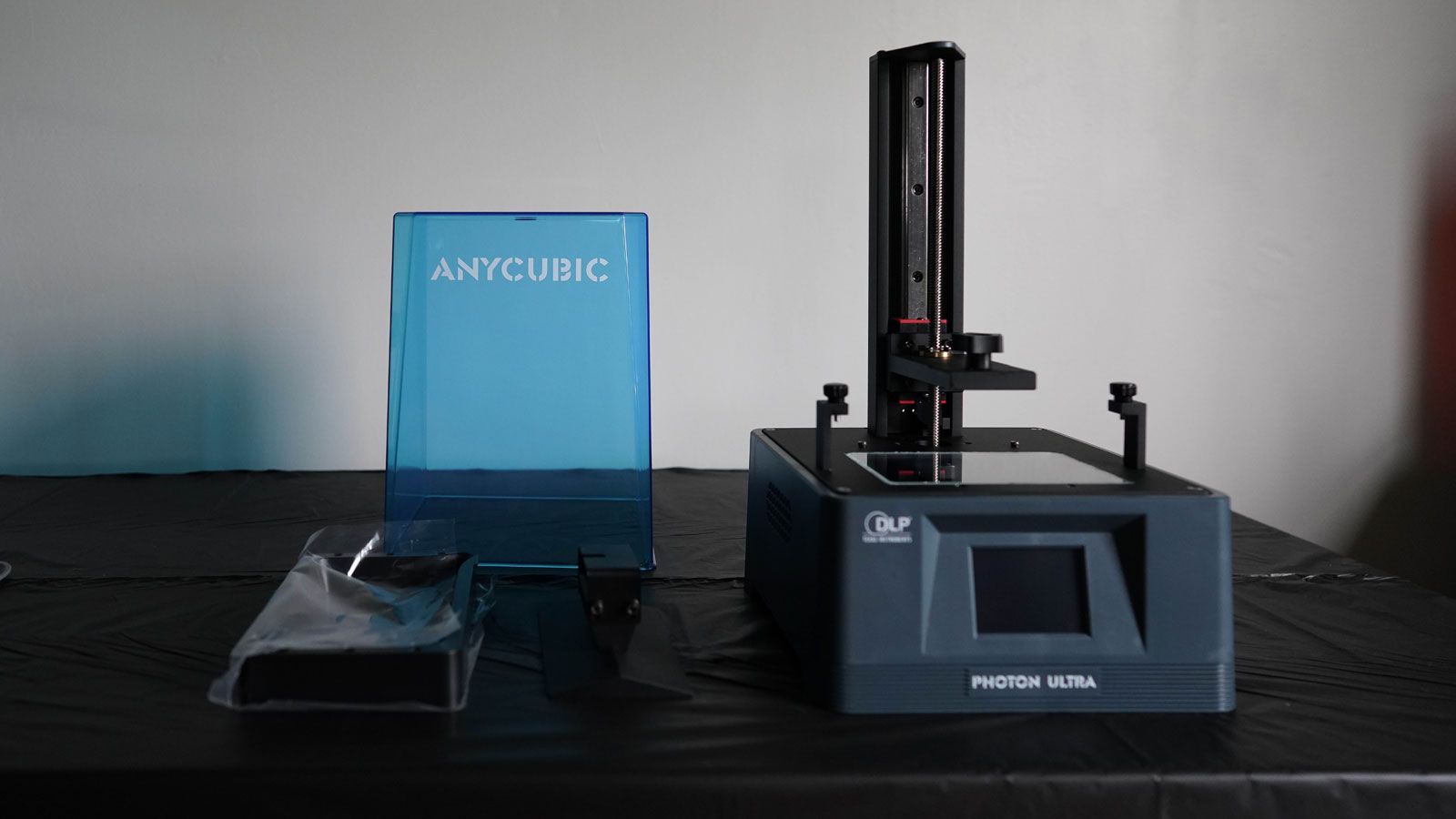

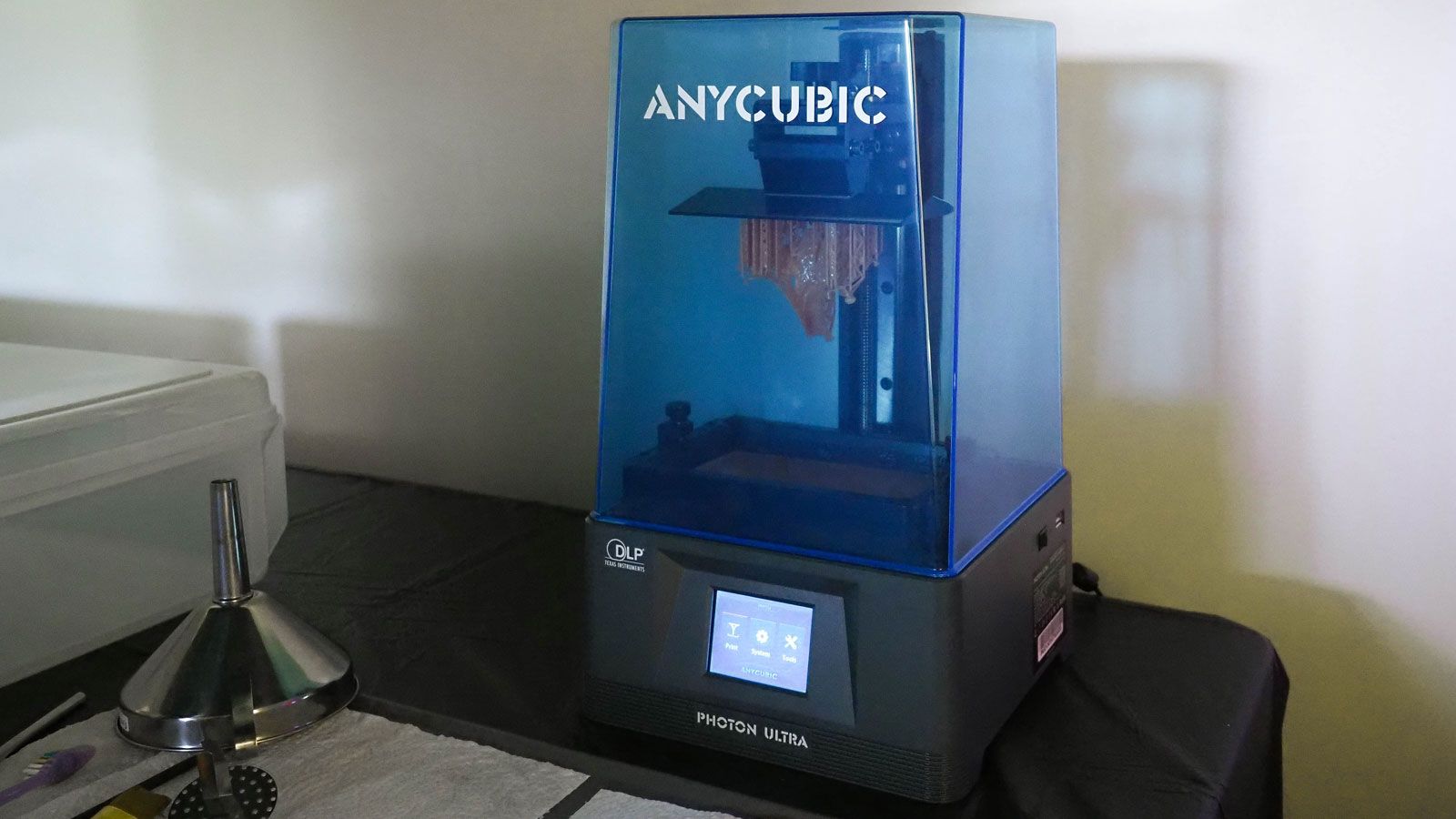

Once you unbox the Photon Ultra, you'll notice it's a relatively small machine that won't take up much space. It measures out at 8.74 x 8.94 x 15.08 inches (222 x 227 x 383 mm) and weighs just 8.8.lbs (4kg). At the top of the unit, you'll notice a metal build; this changes as you go down the unit.

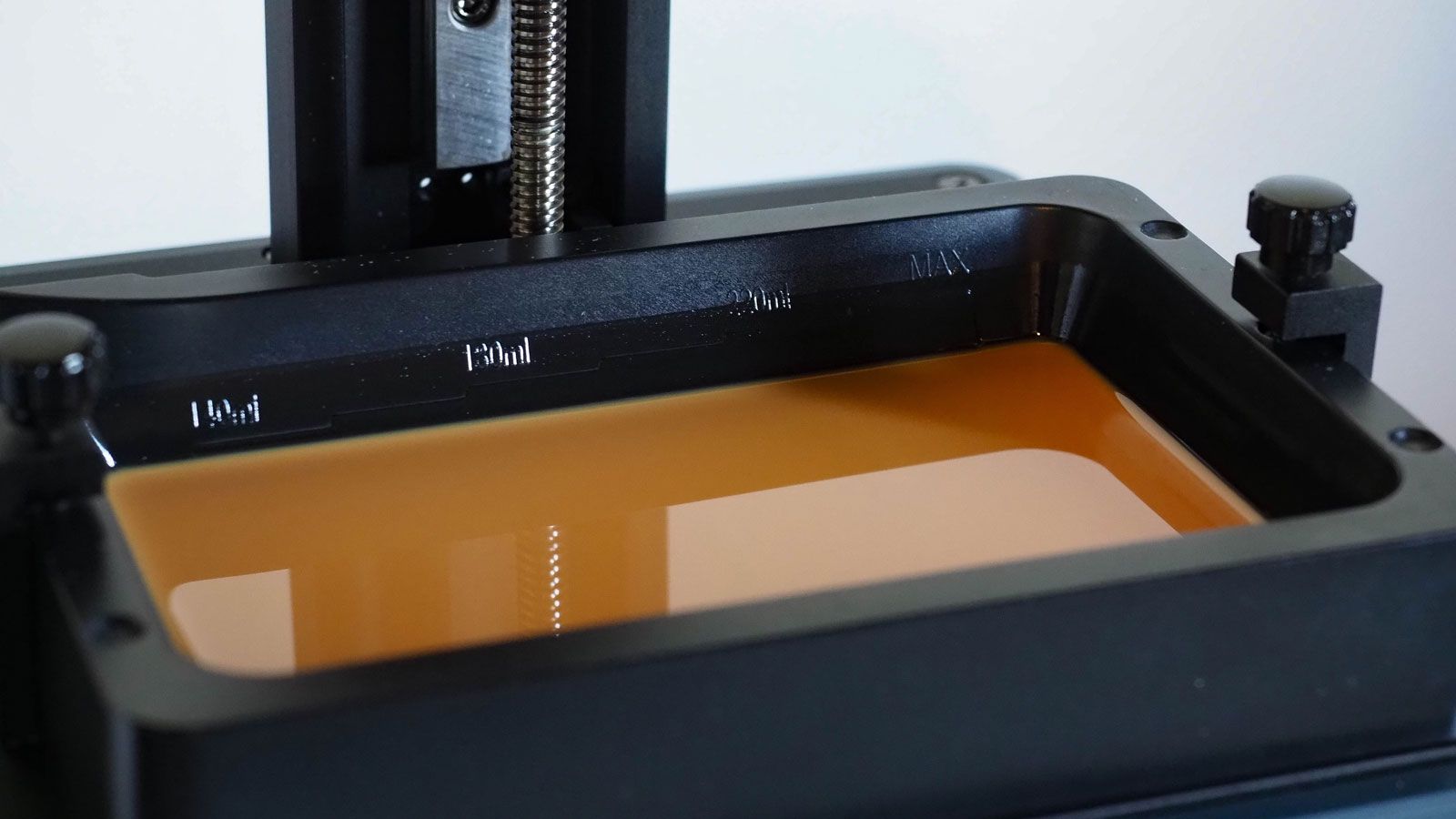

At the base of the Photon Ultra, you’ll notice there's a lot of plastic. Similarly, Anycubic has opted to go with a plastic resin vat for the Photon Ultra. While seemingly a cost-cutting measure in both cases, both were amply durable for everyday printing.

To help move the Photon Ultra safely, it features a raised bottom lip on both sides of the machine. In practice, these simple handholds help with the initial lift. However, the plastic nature of the body also makes the experience a bit rougher to the touch.

At the right side of the unit are the Photon Ultra's power switch and a USB-A port. As standard with many 3D printers, the Photon Ultra prints exclusively from this USB port. So those looking for network compatibility will have to look elsewhere.

Beyond the make-up of the Photon Ultra, there's a focus on quiet operation. To keep the Photon Ultra cooled, it dissipates heat via a radiator. There's no cooling fan on the unit, so this reduces extra noise during the entire printing process.

Anycubic Photon Ultra Touchscreen

For its touch screen, the Photon Ultra has a 2.8-inch color LCD touchscreen. As standard, there’s a simplistic menu that breaks it up into three broad categories with options under each. However, there are some unique offerings as well.

With the Anycubic Photon Ultra you can adjust the UV power on the machine directly. You can adjust the percentage either via a sliding bar or enter your select input manually. For those looking to explore different resin options, this provides some impressive versatility.

There’s also the option to adjust printer settings from the machine itself. So rather than having to go back to your computer and slicer, you can adjust print settings during the process itself. If you forgot to change a setting before slicing, this can help you make changes in a pinch and also allows you to double-check your values.

With that said, the 2.8-inch touchscreen also does have some minor issues. This largely presents in the small size of the touch screen and touch detection. With icons so close to each other, the Photon Ultra would sometimes select the wrong option.

For instance, when touching the selection to start the printing process, I would run into issues where the Photon Ultra would think I selected the delete option for my file. So I'd have to cancel the delete prompt and repeat the process again. Similarly, when manually raising the Z-axis height in increments of 10 mm, I would run into issues where tapping the up arrow would instead result in me selecting 0.1 mm instead.

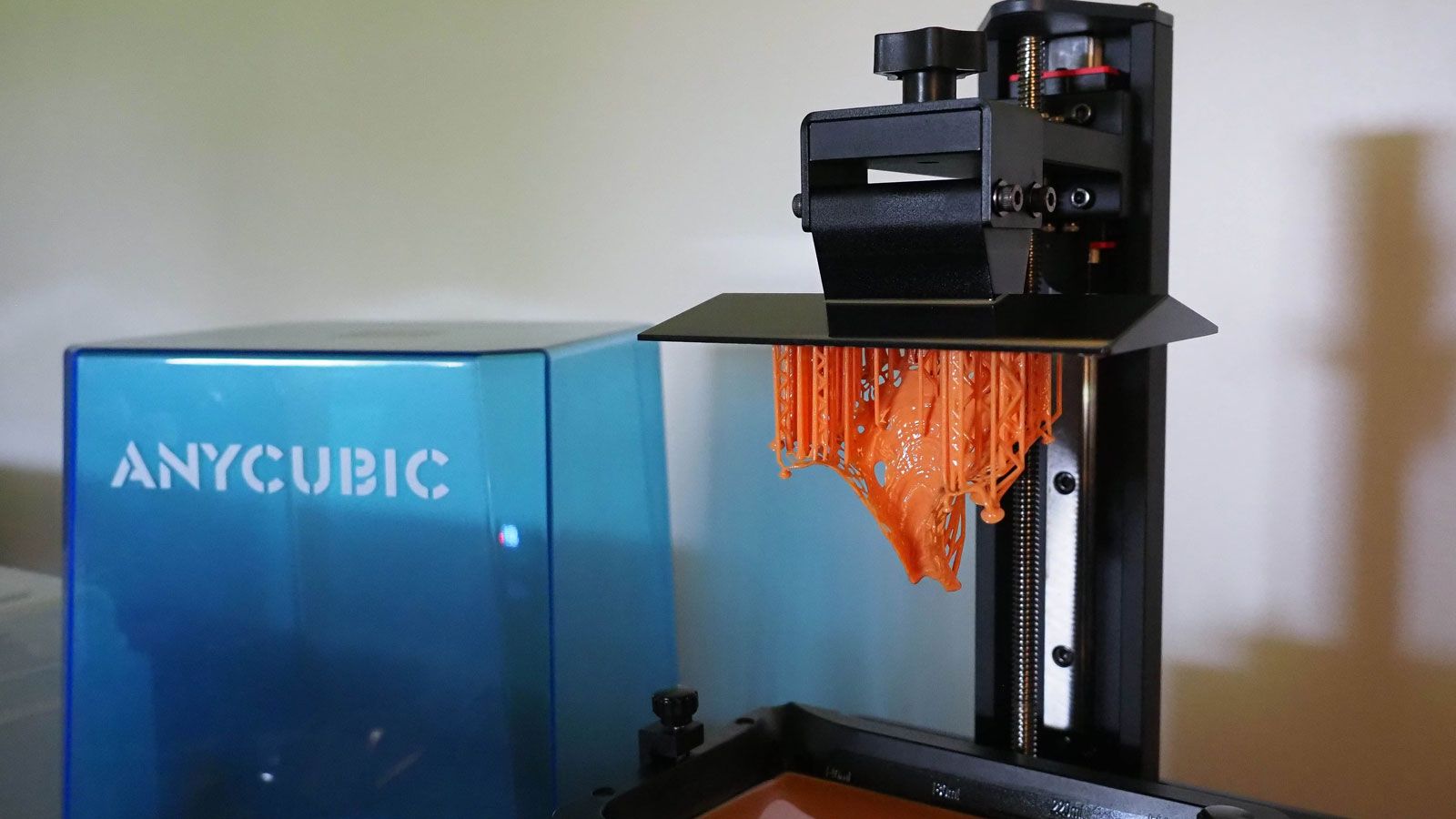

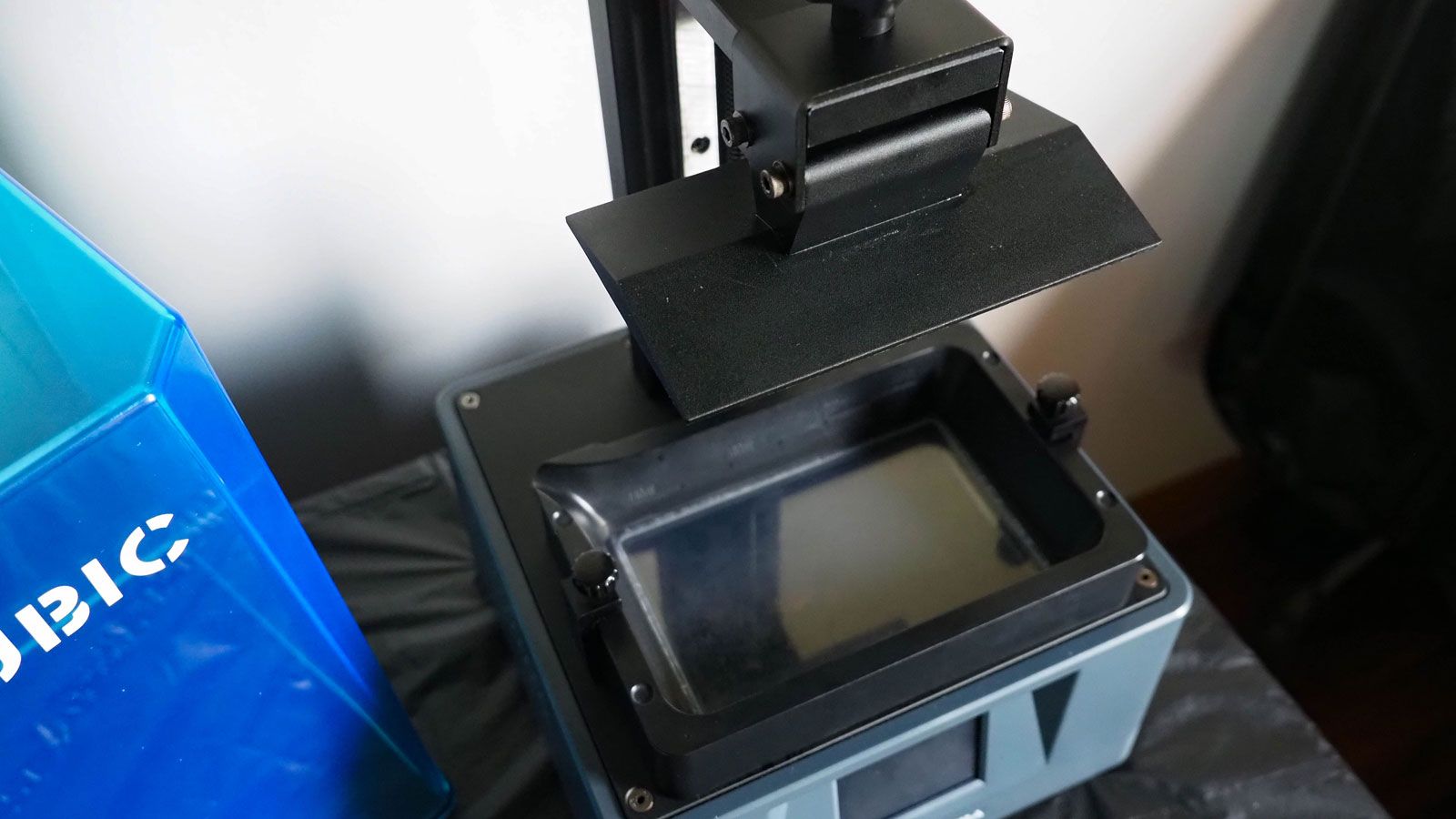

Leveling and the Photon Ultra's Build Plate

Setting up a resin printer can sometimes prove a trying process, and this often hinges around the build plate.

Problems can range from uneven build plates to improper holding of the build plate while tightening the four platform screws during leveling. With the Photon Ultra and its small build volume of 4.02 x 2.27 x 6.5 inches (102.4 x 57.6 x 165 mm), it's easier to keep it held tight, so the latter isn't an issue. Overall, the entire leveling process was very smooth with the included leveling paper removing the need to even cut copy paper to size.

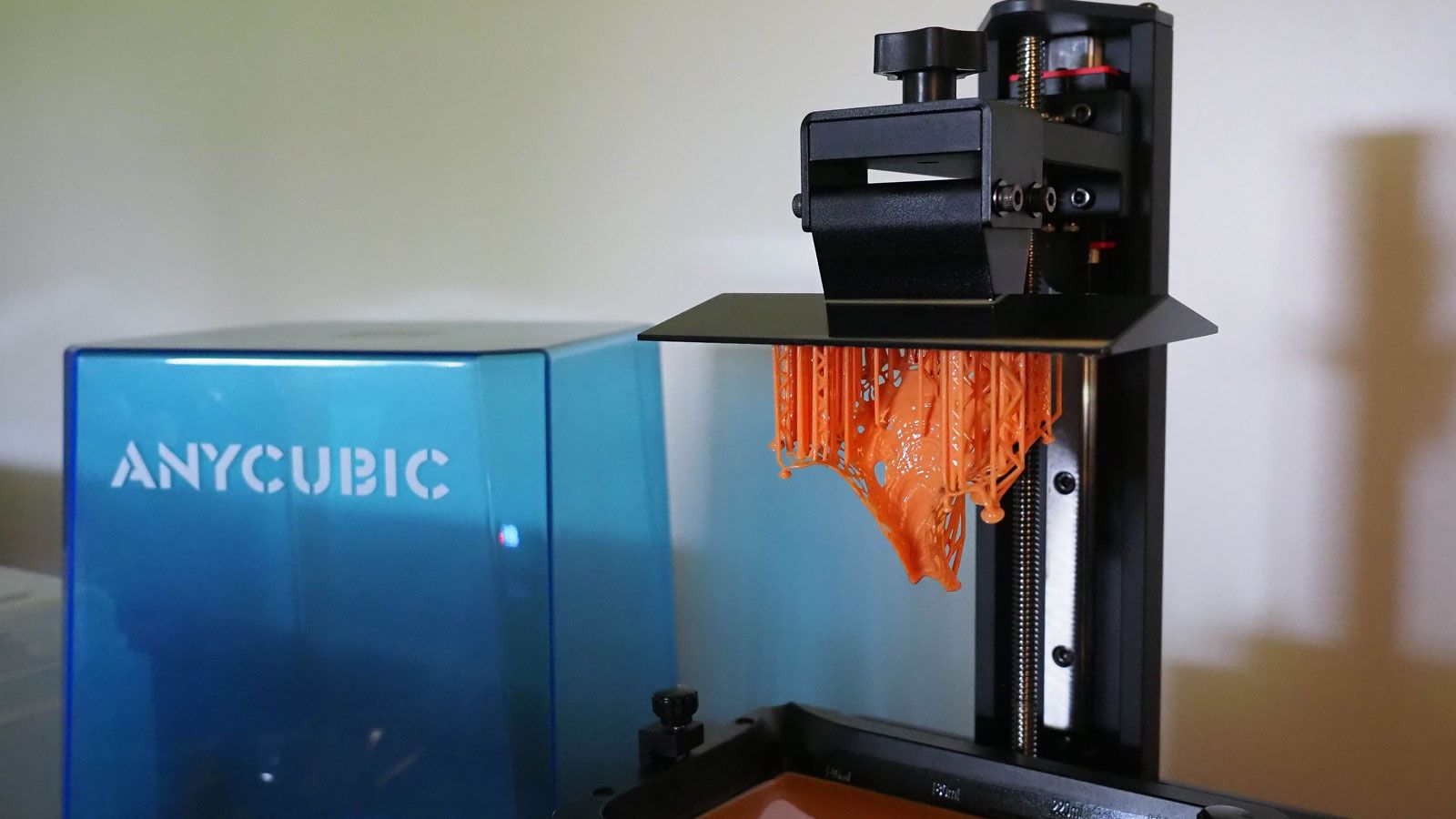

As for the Photon Ultra's build plate, Anycubic has gone with a laser engraved checkered pattern at the bottom of it. This is meant to improve adhesion and also make it easier to improve prints. While I did find the adhesion to be still mostly tied to my exposure time, actual removal from the build plate felt much smoother and faster; I found my metal scraper sliding under my models much more easily.

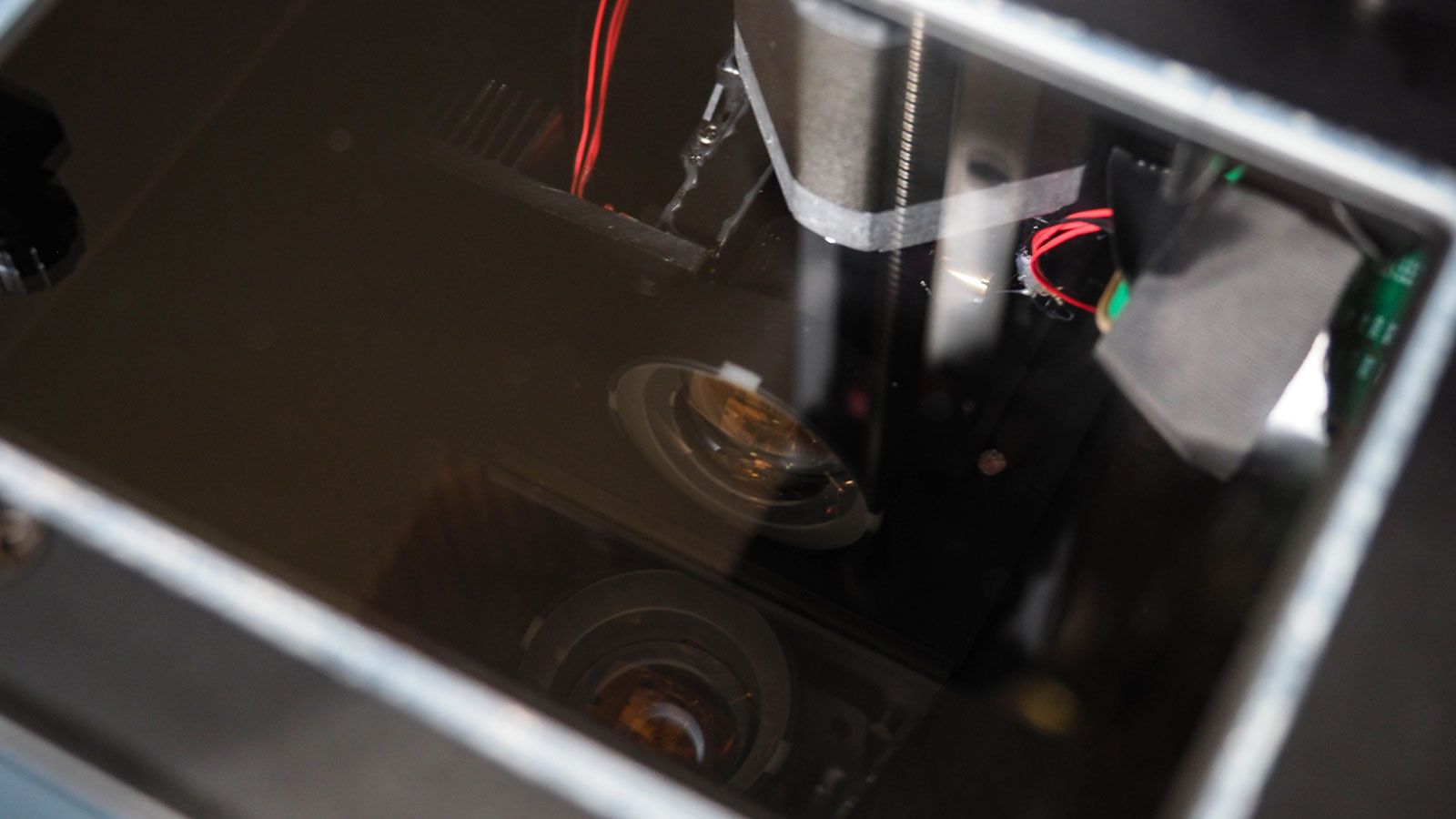

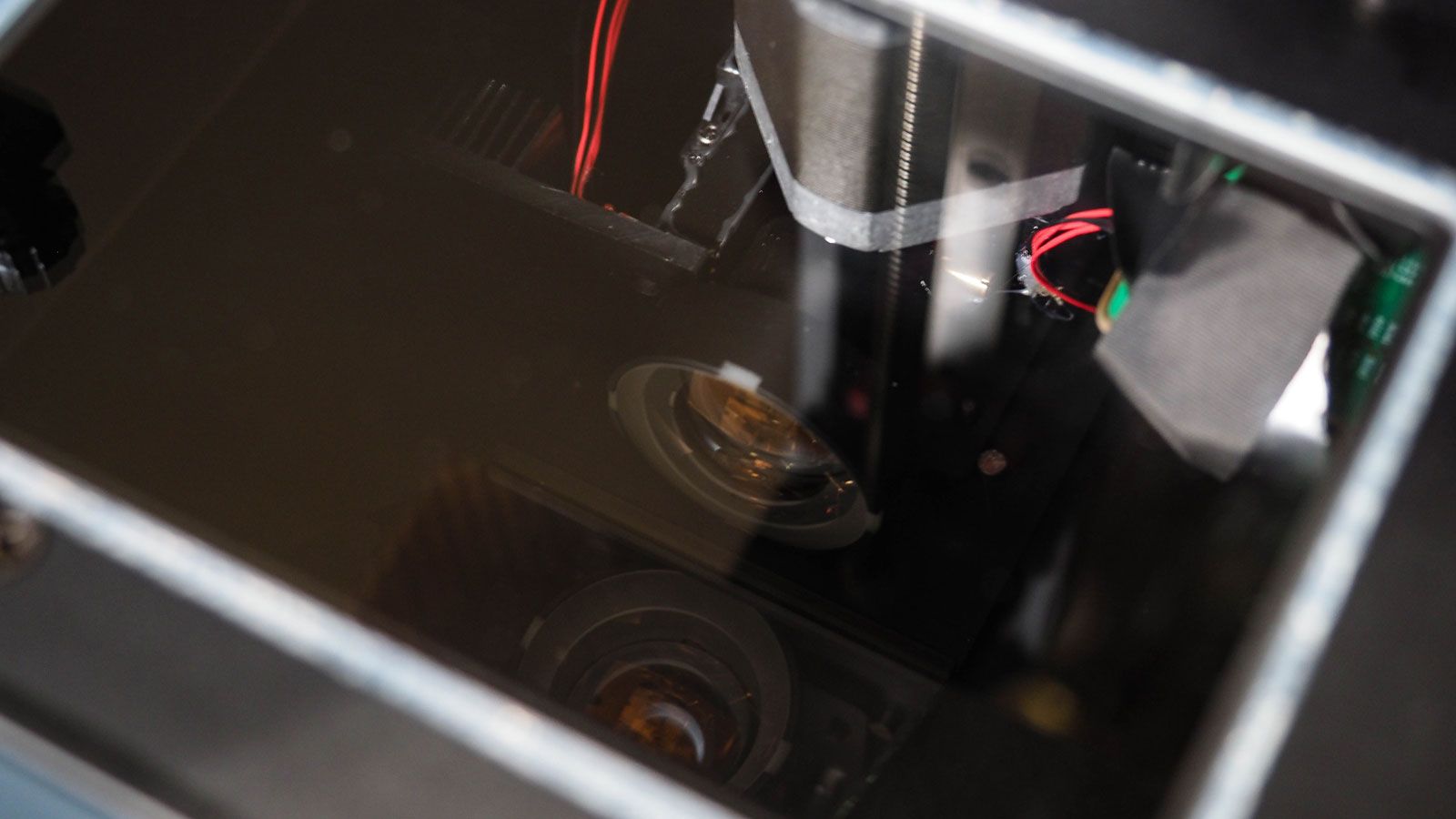

Why DLP Technology?

The Photon Ultra has a lower resolution of 720p, but that doesn’t mean you can dismiss it immediately for 2K and 4K LCD printers. Instead, you need to look at how the technology works.

With DLP printing, there’s a projector and a micromirror that directs light precisely where the resin needs to cure. So you don’t have to worry about light leaks. Whereas with an LCD monochrome screen, you’re dealing with that one big UV light shining through a masking screen.

Because the light is always on, this can result in bleeding over of light into areas that shouldn’t be lit. Comparatively, the precision of DLP's concentrated beam of light allows for cleaner edges and overall crisper prints.

Slicing With Photon Workshop

The Anycubic Photon Ultra currently requires that you slice your print files into DLP format via its Photon Workshop software. As far as slicing software goes, Photon Workshop keeps things more basic; you can always modify files in LycheeSlicer or ChiTuBox before importing them over. In most cases, I would advise this if you aren't preparing for your build plate.

However, this will ultimately boil down to personal preference. I have experienced a few rare crashes and bugs with the version of Photon Workshop that was required for the Photon Ultra. However, it was an overall stable and easy-to-use slicer.

The Photon Ultra Printing Process

To test the print quality of the Photon Ultra, Anycubic provided me with the apricot color variant of its Craftsman resin. When first printing the Photon Ultra's sample DLP file, a bust of Wolverine, I didn't run into any issues. However, I started having multiple failed prints when I moved onto presupported models using its own DLP resin.

After adjusting a variety of printer settings, I still continued to get failures near the start of the process where the initial layers failed and stuck to the FEP. To make sure it wasn't the model, I ended up printing with some leftover Phrozen 4K resin and getting my first successful print since the sample file.

When I reached out to Anycubic, they told me that DLP resin's texture is finer than ordinary resin. Therefore, the printing difficulty also increases when printing delicate models, and thus, the supports need to be thicker.

Now the core of my problem here is that I was using presupported models, but they weren't strong enough for the DLP resin. They're designed for traditional resin printing, in a way that users don't have to deal with the removal of leftover supports.

Now this isn't too much of an issue if you know how to manually support your models or have a slicer editable file to work with. However, it does introduce a learning curve for newer users looking to work with Anycubic's suggested DLP resins. Once I got a handle on figuring out the required support thickness and density, I got my first look at the high resolution of these DLP prints.

Beyond the resin, however, there was an issue with the USB slot that appeared on-and-off with the Photon Ultra. Firstly, there’s a more minor annoyance where when the USB is inserted into the slot, the Photon Ultra won’t register anything has been inserted. This can sometimes repeat a few times even if you power the machine on and off or reinsert the USB drive.

The more major issue is the U-disk error. This is where the Photon Ultra believes the USB was removed during the printing process and will stop printing. So if you’re in a few hours on a print, only for it to cancel midway (say if you’re printing overnight), a lot of time can end up wasted.

I also couldn’t really predict when this would happen.

If the USB was having issues being detected, it would sometimes follow that. But oftentimes it’d be a completely normal print procedure only for it to happen midway. I have even had the error occur as the build plate just begins its initial descent towards the resin vat.

DLP Print Results Versus 4K Monochrome LCD Screens

When it comes to print results, the question is does the quality of the Photon Ultra stack up? Towards this end, I printed a variety of miniatures from Cobramode of different sizes. And I was able to get some really impressively detailed prints.

Given the precision of the DLP light source, I wanted to challenge the printer's capabilities. So I looked for models that were detailed with plenty of curvature and indentation as well. Now if you've worked with LCD printers for a while, you'll run into some blurred edges on your models.

With the Photon Ultra, I consistently got very clean, detailed prints. While I'm used to working on bigger-sized prints where I might not notice a degree of detail blurring or otherwise work around it with paint, I was able to take all of my small print results and really take in the degree of small detail transference from the 3D model to the print itself.

In terms of model durability, I also was impressed with the resin once it was cleaned and cured. Small, delicate pieces were still vulnerable to potential breakage; I wouldn't expect differently from ordinary resin in those cases. However, the main body pieces sustained fine against tests such as a minor topple.

Maintenance Costs and Upkeep

One of the big selling points of the Photon Ultra is that as a DLP printer, there's no LCD screen to replace. Instead, the projector is guaranteed for 20,000 working hours. Given the average working time of an LCD screen is 2,000 hours, this equates to a working time of ten screens---more than enough for most users.

You’ll still need to replace the FEP around every fifty prints or as signs of degradation appear. Replacements can be acquired via Anycubic's online store, or you can cut FEP sheets to size.

But if you keep the resin vat clean and the FEP in good standing, maintenance should be minimal. LCD screens can add up for frequent printers, so DLP printing offers large savings over the lifetime of the printer. Additionally, the Photon Ultra offers additional power savings by operating with an energy consumption of just 12W.

Should You Buy the Anycubic Photon Ultra

When it comes to the question of whether you should buy the Anycubic Photon Ultra, the answer is a yes for most with some caveats.

The Photon Ultra can produce very detailed and crisp prints, but you’re going to be size-limited to an extent. If you’re not looking to fill a build plate or print very large models, this isn’t much of an issue. But for use with miniatures, jewelry, and other small custom work it’s a great resin printer.

My only true concern with the Photon Ultra really hinges around its USB port; it alone doesn't give me true pause. Overall, as you consider the quality of its prints and the lifetime savings of using the Photon Ultra, it's not hard to see the appeal of a budget-friendly DLP printer.