Most of the things that involve computers are solitary endeavors. Writing. Programming. Building electronics projects. It's not unheard of for creative-minded geeks to lock themselves away for days at a time, isolated from the world, and hack away on their projects.

But the problem is, that's not particularly healthy.

People are social animals who crave interaction, and affirmation. They're collaborative beasts. Which is why countless developers, digital artists, makers, and engineers have launched 'makerspaces'.

What Is A Makerspace?

Makerspaces - also known as 'hackerspaces' and 'hack labs' - exist to provide a common space (and often the raw materials) for members of the local maker community to work collaboratively on creative projects. Overwhelmingly, makerspaces are operated by the community, for the benefit of the community, and without any profit motive.

Some even offer 'hotdesking', where freelancers and remote workers can informally hire a desk for a short period of time. This affordability, and lack of commitment, has resulted in thousands of startups being born in Makerspaces.

There's a plethora of reasons why someone might want to open their own makerspace. From laying the groundwork of a maker community, to making new connections and acquaintances.

But it needn't be expensive, either. Kitting out your own makerspace can be done cheaply, without having to make any compromises on equipment. Here's a shopping-list for anyone hoping to make their own makerspace on a budget.

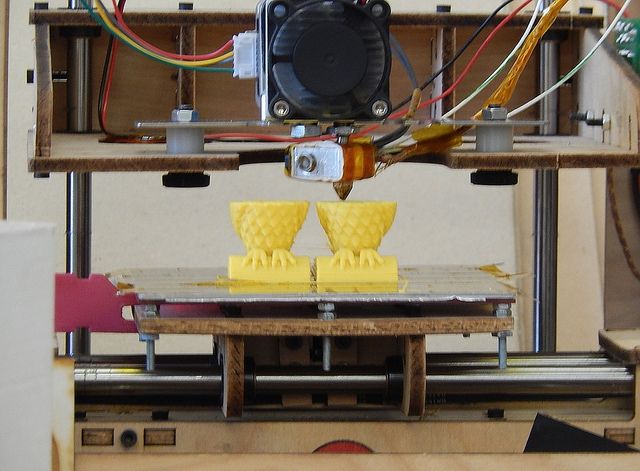

3D Printer

Hardware startups are having somewhat of a renaissance right now, due to the fact it's never been easier to build a physical product. Just create a mockup of your product in your CAD program of choice, and using a 3D printer, wait whilst it's transformed into something tangible.

The engine powering this process is the 3D printer which, once novel and eye-wateringly expensive, has became affordable. They work by taking a pliable string of polymer, and melting it until it's sufficiently viscous. The machine then spurts it out layer by layer until it resembles the shape of your design. That's it.

3D printers are a must for any makerspace. But choosing the right 3D printer for you can be confusing.

There are a plethora of 3D printers to choose from. The cheapest is arguably the Peachy Printer, which costs just $100. For one Benjamin Franklin, you get a quiet, highly customizable printer, based entirely around free-libre open source software. However, some assembly is required, and this is still in a pre-order phase - with new orders currently expected to ship in October 2015.

The next step up in sophistication and quality is the XYZPrinting Da Vinci 1.0 3D Printer, which costs just shy of $500, and offers an expedient and safe printing experience, with the ability to print larger items.

Some 3D printers cost thousands of dollars, like the Makerbot Replicator 2. So, when you spend more money, what do you get in return? In short: higher resolution prints, vastly improved quality – with some 3D printers able to make store-quality products.

Ultimately, it comes to what your budget can bear.

Laser Cutter

But what if you don't want to just work with plastic?

Laser cutters work on a similar principle to 3D printers. You pass them a computer-designed schematic, and it'll then set about making it. But rather than applying layer after layer of hot, molten polymer, it instead uses a high-intensity gas laser to cut through paper, cardboard and wood, or to make engravings.

There are plenty of examples of people using laser cutters to build beautiful physical products. A great example of this is the Arduino-powered WhereDial, which was built at the DoES Liverpool makerspace with laser-cut plywood and perspex.

Laser cutters are versatile, and powerful, but also extremely expensive. Units costing thousands of dollars are the norm, not the exception. Of course, there are some bargain basement laser cutters to be found, if you look hard enough. These involve some pretty big compromises though. The cheaper units often come with smaller cutting surface areas, and boast slightly less powerful lasers.

If you just want to engrave wood and plastic, you can settle for the Arduino-powered SunWin Mini Laser Engraving Machine, which costs a palatable $145.

But if you want something a bit more powerful to actually cut through things, you can expect to pay much, much more. Full Spectrum Laser successfully crowdfunded their H-Series laser cutter, bringing to the market one of the most affordable cutters yet, at $3,499. But that's still out of reach for a lot of people.

A happy compromise can be found on Ebay, which is littered with affordable laser cutters. Some of which are second-hand, but others coming from no-name Chinese manufacturers.

A cursory glance at Ebay US showed a 40W Co2 laser cutter from an Asian OEM for only $400, plus $200 shipping and handling.

Of course, one should always be wary when buying equipment from a manufacturer you're not familiar with.

Vacuum Former

Vacuum formers are a time-honored tool used in manufacturing. They work by taking a single sheet of a meltable, pliable polymer, and pulling it down against a mould, thereby creating a like-for-like facsimile of it.

These are often used in industry to build plastic-based products at a large scale. But there are smaller, and cheaper vacuum formers, which can comfortably fit in a workshop, and would make a fabulous addition to any makerspace.

When it comes to vacuum formers, you've got a lot of choice.

Sitting at the bottom end of the vacuum former market are homemade, DIY vacuum formers, which can be bought easily on Ebay. These work by using your kitchen's oven to heat the plastic, and then affixing it to the mould through light suction, provided by a shop-vac. The cheapest units of these cost around $45 for the smallest model. Larger models cost more.

If you can only foresee yourself making small moulds, an affordable way to get a vacuum former is to purchase a dental moulding machine. These work on the same principles, but are smaller. Cheaper, too, with some generic models costing only $160 on Amazon [Broken URL Removed].

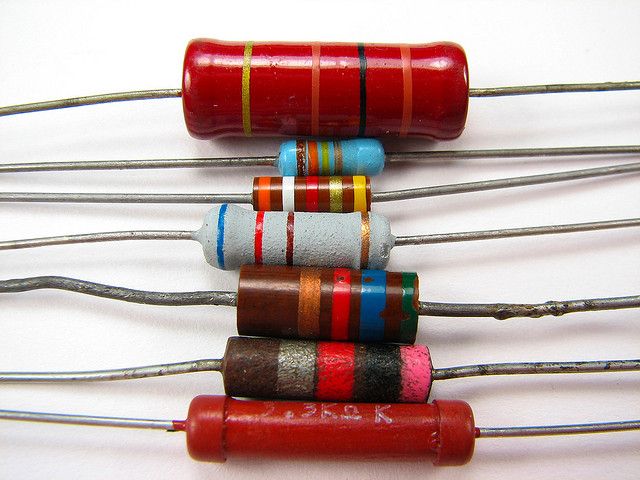

Electronics Gear

Every makerspace worth their salt has a decent arrange of electrical engineering equipment. Because, let's face it, once you've made your beautiful 3D printed product, you're going to want to make it do something.

But unlike the previous tools we've discussed, it's relatively cheap to kit out a makerspace with some usable electrical engineering gear.

First, you'll need some good soldering equipment. This usually means a soldering iron, and somewhere safe to put it when not in use. At $30, the Aoyue 469 Soldering Station offers a solid 60 Watt soldering iron, plus a sponge, and holder for when not in use.

In our article on soldering tips for beginners, Guy McDowell also recommends some decent safety eye-wear, plus a fume extractor.

Soldering is a tricky, difficult business, and one that requires precision, particularly when dealing with components that can be as small as a grain of rice. The SE MZ101B Helping Hand is ideal for those circumstances. For your $6, you get a magnifying glass that can be fixed into a set position, and adjusted as required, making it easy to solder even the tiniest components.

No electronics kit is complete without a multimeter. These allow you to measure current, voltage, and resistance, in one small package. Prices for Multimeters range from $10, to multiple thousands for laboratory grade kit. The INNOVA 3320 costs just shy of $20, and is the top-selling multimeter on Amazon, but if you want more accuracy, you could consider the Fluke 115. Accuracy comes at a price, however – the Fluke costs around $155.

Miscellaneous

Finally, it's good to have some general purpose supplies for creative working.

It's always good to bulk-buy resistors, capacitors, LEDs and other electrical goods, and make them available to your users. You can recoup your costs with an 'honesty box'.

If you decide to turn your makerspace into a co-working space as many have done, you'll need some office furniture. This can be acquired at no cost from Freecycle, or on Craigslist.

Some makerspaces offer refreshments to their users at a reasonable price. Of the ones I visit, the majority bulk-buy snacks and soda from Costco, with users dropping a few coins into an honesty box for what they consume.

Thinking Of Founding A Makerspace?

Perhaps you've already founded one. Either way, I want to hear about it. Drop me a comment below, and we'll chat.

Photo Credit: Makerspace der SLUB by SLUB Dresden, Wheredial (Cory Doctorow), Vacuum Former (Does Liverpool), Liverpool April 2014 (Mitch Altman), Resistors (Windell Oskay), 3D Printer In Action (Michael Coughlan),Ada Lovelace Day Attendees (DoesLiverpool)