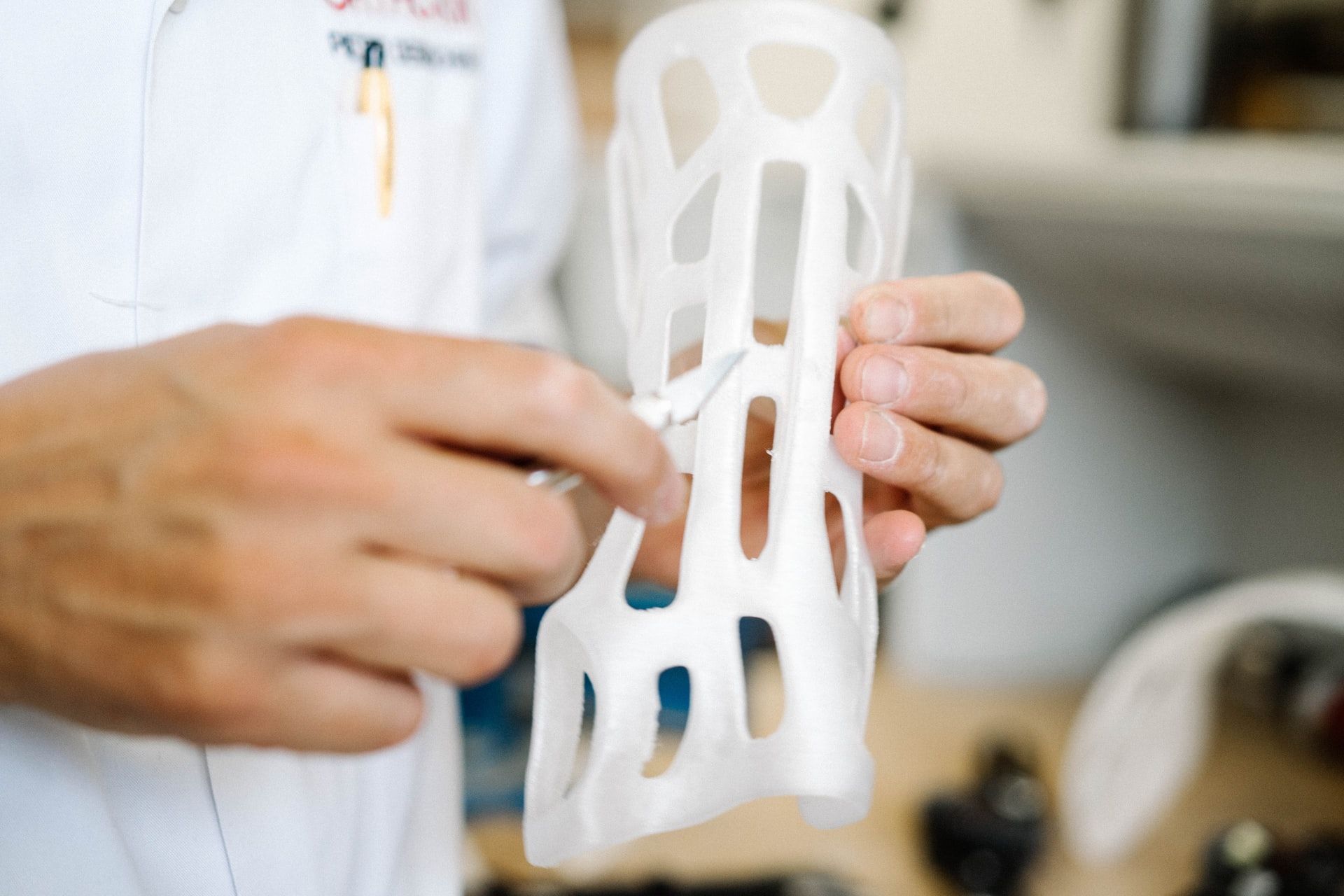

The massive amounts of applications for 3D printing are mind-boggling. These devices have revolutionized designing and manufacturing everything from replica body parts to firearms, robotics, food, and more. Better still, you can be part of this second industrial revolution.

But, just as there are multiple types of 3D printers, did you also know there are a variety of printing materials you can use, all with advantages and disadvantages?

So, here's how you choose the right filament for your 3D printer.

What Makes a Filament Safe?

Some 3D printing filaments feature excellent biocompatibility and are great for medical and food applications. Other materials can withstand the elements, with rain, chemicals, and rapid temperature changes doing little to harm them. There are three main areas we will explore with each of the filaments we look at.

- Biocompatibility: Biocompatibility is how something works with the human body without any adverse effects.

- Safety during printing: Some filaments release chemicals during printing, causing a negative impact on your health.

- Chemical resistance: Filaments have different levels of resistance to chemicals, making some better than others at keeping their strength and durability.

Different 3D Printing Filaments and Their Safety

By taking a look at each of these factors, you can determine which filaments are best for which applications while also ensuring that you are always looking after your health while 3D printing.

PLA

PLA stands for Polylactic acid and is possibly the most common filament used for domestic 3D printing. It comes in two flavors of rigidity, with one being significantly more shatterproof and flexible than the other. In addition, the production of PLA is fascinating, as it is produced from a corn by-product rather than through oil processing.

- Biocompatibility: PLA offers excellent biocompatibility and is often used in the medical field for this very reason.

- Safety during printing: PLA is very safe during printing, as it releases very few chemicals that can harm your body.

- Chemical resistance: Unfortunately, PLA isn't very resistant to certain chemicals, with water damaging this material over time.

PLA offers relatively high strength for a filament that is so easy to print with. This makes it one of the first filaments many people work with, while also making it a great choice for most home 3D printing projects.

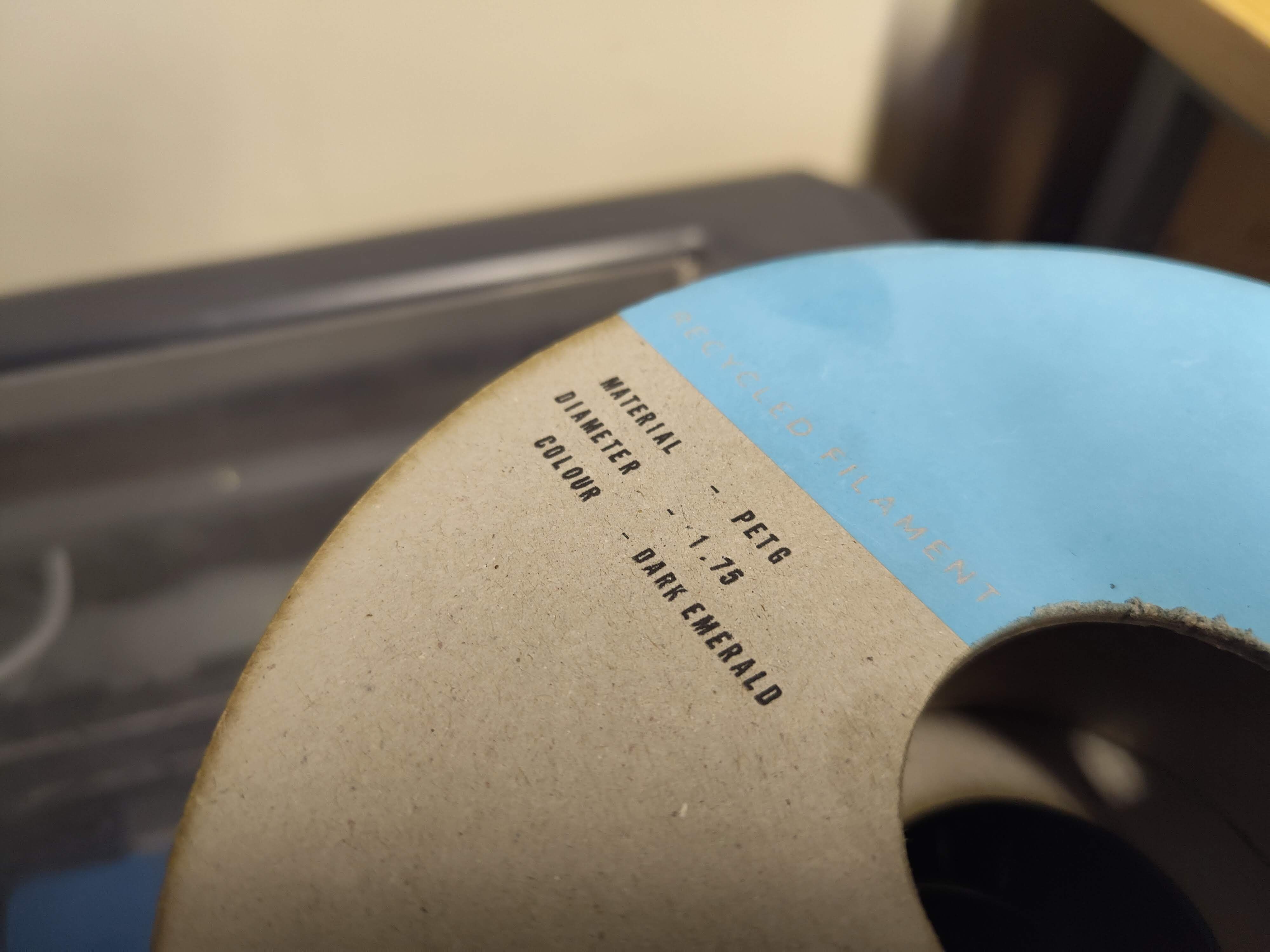

PETG

PETG is an adaption of Polyethylene terephthalate (PET) with glycol added to the mix. PETG offers greater strength than PLA, while also being slightly flexible. PETG is naturally transparent and most of the filaments you find on the market reflect this.

- Biocompatibility: PETG offers similar biocompatibility to PLA, and it is also used in medical and food applications. Most drink bottles are made from PET.

- Safety during printing: Much like PLA, PETG is very safe during printing, requiring minimal ventilation for good results.

- Chemical resistance: PETG is ideal for outdoor use, with incredible chemical resistance that can beat substances like acetone.

While harder to print with than PLA, PETG is relatively easy to get started with. Of course, printing with an enclosure will make it easier, and you will likely need to change your 3D printing settings quite drastically to get good results.

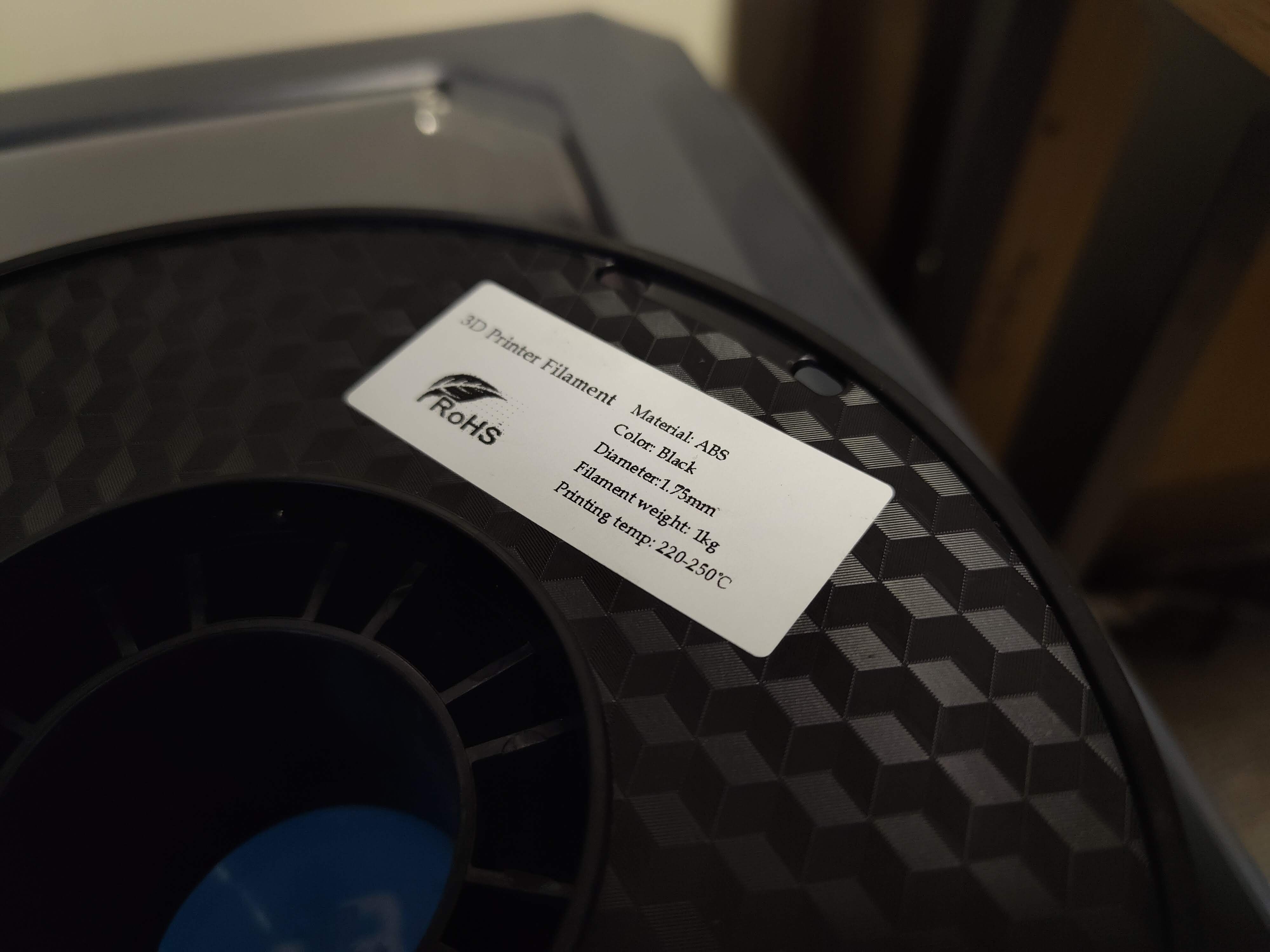

ABS

ABS stands for acrylonitrile butadiene styrene. It is one of the most popular plastics on the market for 3D printing and manufacturing. ABS is known for being strong and impact-resistant, providing an excellent material for parts that have to deal with stress.

- Biocompatibility: ABS is considered biocompatible, though it isn't as popular for food or medical products as PLA, Nylon, or PETG.

- Safety during printing: ABS releases styrene gas while being printed. This gas is carcinogenic, making it crucial that ventilation is in place.

- Chemical resistance: Much like PLA and PETG, ABS is resistant to a lot of chemicals, though it will completely dissolve in acetone.

ABS is a notoriously challenging material to 3D print with thanks to poor bed adhesion and a tendency to warp. A heated bed and enclosure are required to print ABS, but you also need to ensure that your room is ventilated.

Nylon

Did you know that Nylon is a portmanteau of New York and London? It's true. It's also true that Nylon has been around the block a few times, and since its invention in the thirties has found a multitude of use both in the consumer sphere and in military applications.

- Biocompatibility: Being used in medical and food applications, Nylon is highly biocompatible and ideal for use in human bodies.

- Safety during printing: Nylon is thought to give off a VOC called Caprolactam when it is printing, making an enclosure crucial to your health.

- Chemical resistance: Nylon is highly resistant to chemicals, including alcohol and even acids.

3D printing with Nylon requires patience and a delicate touch. This material warps like ABS and is just as stretchy as PETG, but the results are plastic with much greater strength than either of these materials.

Flexible 3D Printing Filament

So far, we've only looked at filament options that are rigid when they are printed. There are a lot of other types of materials on the market, though, and flexible 3D printing filaments have become very popular in recent years.

Let's take a look at how some of these options stack up.

TPU

TPU stands for thermoplastic polyurethane and is a flexible printing material with qualities that match rubber. This means that TPU can stretch or bend and bounce back while also being great at dealing with impacts.

- Biocompatibility: TPU is highly biocompatible, providing a material used to create synthetic tendons for humans.

- Safety during printing: Like PLA, TPU is safe to print without an enclosure, though it might smell a little.

- Chemical resistance: TPU has one of the highest chemical resistance levels of any of the filaments on this list.

Alongside being a safe filament to 3D print with, TPU is also quite easy to use. Print settings similar to PLA can be used for it, though you need to make sure that you play with your retraction settings to avoid oozing.

TPE

Thermoplastic elastomer (TPE) is the final 3D printer filament option we will be exploring. This filament shares very similar characteristics to TPU, though TPE is less rigid than TPU and has a different range of applications.

- Biocompatibility: TPE shares TPU's excellent biocompatibility, offering a filament that can be used with food, drink, and organic bodies.

- Safety during printing: TPE is also very safe to print with and doesn't require an enclosure.

- Chemical resistance: Like TPU, TPE offers great chemical resistance, making it ideal for industrial applications.

TPE is just as easy to print with as TPU, though its lower rigidity means that you need to increase retraction and low print speeds even further. Nevertheless, TPE is a popular material for clothing and footwear.

Choosing the Right 3D Printer Filament Material

Choosing the right material for your next 3D printing project doesn't have to be a challenge. There are countless options on the market, and you can almost certainly find something that will be safe enough for you.

Of course, though, safety isn't the only consideration you need to make when you are looking at filaments for 3D printing. You also need to think about material strength, flexibility, and ease of printing when picking the materials you want to work with.