Have you ever got tired of cleaning out your PC’s dust bunnies? Or have a rattling fan that just ruins your concentration? Believe it or not, fixing both problems can cost just dollars and the results provide coolness, silence and easier maintenance.

Getting started requires only one of the following - machine lubricant, a PC dust filter or pantyhose, although you can use all three if desired. However, keep in mind that these methods mostly apply to desktop PCs. For laptops, while you can easily build your own dust filter and grease its fan, you are better off first applying conventional methods because of their complex inner workings.

On the other hand, desktops are simple. The first part requires that you apply grease to a rattling fan. In the second part, you will attach a screen to your computer’s air intake vent. As an alternative to the second part, you can optionally build your own dust filter using simple, household items.

Part One - Silence a Rattling Fan With Grease

Rattling fans produce loud noises because they have suffered a bearing failure, a fault common to both sleeve and ball-type fans. When a failure occurs, it means the lubrication greasing the sleeve or ball bearings has dried out, causing the bearing to grind on plastic. Fortunately, regreasing the fan's bearings will often fix the problem.

Though, of the many kinds of fan technologies on the market, some cannot receive lubricant; however the vast majority of low quality fans that come with cases can receive external lubrication. Ironically, cheaper fans have less expensive maintenance than high quality ones.

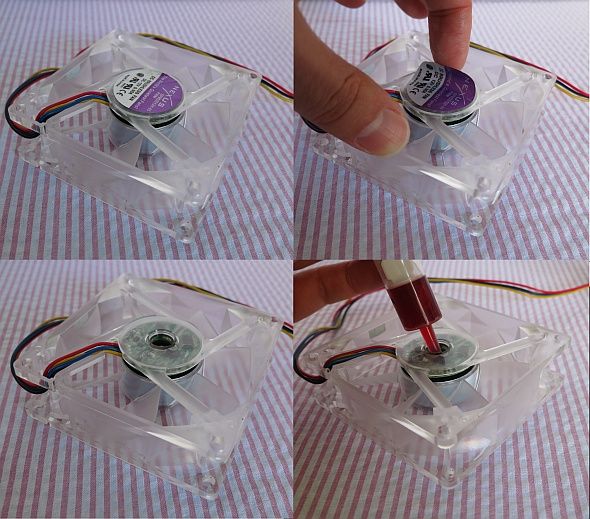

Determining your fan’s compatibility requires only that you remove the sticker covering its back and, in some cases, wedge out the rubber plug. Look closely at the area that was behind the sticker. If you see a raised metal nub, and there’s already applied grease, then this method will work. If not, skip to the second part.

Once you've removed the sticker and rubber plug on your fan, apply lubricant onto the raised metal nub. Only a small amount is necessary as the rotational forces of the fan will pull the grease into its inner workings, which will then coat the dried-out bearings.

For this particular exercise, I used a high-grade grease (non-conductive) rated for 2,000-3,000 RPMs. A thinner lubricant will suffer from separation at high speeds, which causes the grease to literally separate from the surface it coats. And, never, ever use WD-40.

Overclock.net user ehume specifically warns against using 3-in-1 lubricating oil. His reasoning revolves around the presence of a "penetrant" in 3-in-1, similar to WD-40.

How you apply the grease doesn't really matter, although in my example an old needleless veterinary syringe finally found a use.

In an ideal situation, a small amount of lubricant will silence the fan and restore full speed. However, if you’ve let the fan rattle for years, it’s likely that the bearing will have worn itself out and requires replacement.

I don't suggest greasing a laptop's fans as it requires a great deal of assembly in most models. However, lubrication has had tremendous impact on several of my laptops, you should consider some of these less invasive methods before popping your mobile computer open.

Part Two: Get Fan Screens

Fan screens don’t cost very much and can attach to your computer quite easily. My two favorite types are the SilverStone magnetic filters and the StarTech filters. Simply measure your case’s intake vents horizontally or vertically and buy a matching size. For example, you will want to match a 120mm opening with a 120mm dust filter.

As you might imagine, the SilverStone magnetic filters attach to your PC through small magnets. The design makes removal and cleaning remarkably easy: simply remove and wipe the dust off.

On the other hand, the StarTech filters require fastening via screws. Fortunately, they have a removable plastic top, which holds the filter. These, like the magnetic variety, attach externally to the case, which allows for quick removal and cleaning.

To install it, I merely removed the screws on the intake duct and screwed the StarTech filter in its place. There were some holes that went uncovered, so I covered them with electrical tape.

Out of the two kinds, I prefer the StarTech filters, partly because of their low price, but primarily because the filter material is quite good and pops out easily.

Part Three: MacGyver Your Own Screen (Optional)

Optionally, using common household items or after a visit to the hardware store, you can choose to build your own filters. To get started, simply measure the size of your PC’s air-intake vents and cut an appropriate length of material to fit its opening. I've heard of pantyhose and screen from a screen-door being used with great success.

There's some variation on this method. For example, Reddit user Tw1tchy3y3 suggests using air purifier replacement filters, rather than pantyhose.

I suggest electrical tape or the amazing, adhering substance known as duct-tape, to fasten the material in place. Pretty much any adhesive will do. However, you will probably want to avoid using extremely powerful rare earth magnets as fasteners.

Conclusion

For those of us experiencing issues with dust or fan noise, fixing either of these issues doesn't require much effort or money at all. Using the two methods outlined in this article, adding a dust filter and lubricating a rattling fan, will improve long-term cooling, ease of maintenance and acoustic qualities.

However, for those completely sick of constantly cleaning the dust out of their PC, you might want to check out water cooling, which is an entirely silent and efficient means of keeping your computer running cool.

Image Credits: Pantyhose, Screen Door and Computer Fan via MorgueFile.com