3D scanners have revolutionized how we gather structural data, drastically helping with replications. From minuscule model projects to full-on cars, their possibilities are only limited to your imagination.

Even though the technology is incredible, and there are several fantastic benefits to using a 3D scanner, the entry price point is still a little high for most consumers.

Because of this, it's essential to understand exactly what you can get from a 3D scanner today and whether the pros outweigh the cons of what you hope to accomplish.

How Do 3D Scanners Work?

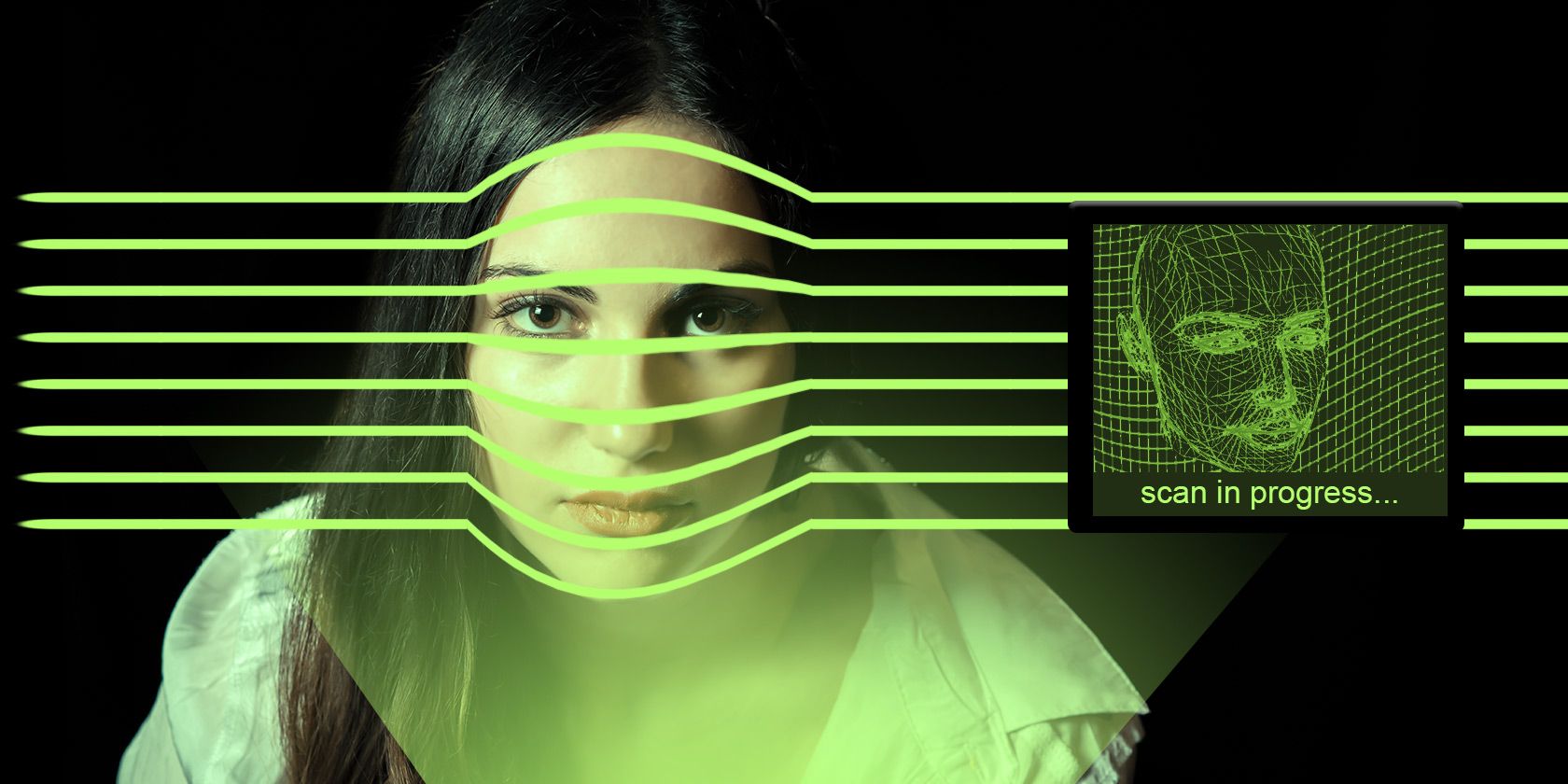

3D scanners collect information about objects within a set visual field, but unlike cameras, 3D scanners collect information about an object's position in space instead of its color and appearance. This is possible by calculating the distances between the scanner and various points of an object's surface.

Generally, 3D scanners can be sorted into two different types: contact scanners and non-contact scanners. As the name suggests, contact scanners require direct contact with the object utilizing touching probes that perform the scanning. In contrast, non-contact scanners use laser light or radiation (such as X-ray or ultrasound) to gather information about the object.

One current limitation of 3D scanners is that they can only capture information from visible surfaces of an object within the camera's line of sight. That being said, the inner composition and the surrounding areas cannot be captured in one motion.

Because of this, to get a full 3D rendering, many different scans from many different vantage points must be compiled into a single file. Since the initial release of 3D printing technology, the time it takes to complete complex scans has drastically shortened.

A laser is shone onto the object of interest (different models can use either a single laser point, a laser line, or a series of linear projections), which then reflects the laser back to the scanner. The scanner also has a sensor that collects data from the laser(s) about the object's shape (calculated based on the angle of the returning light).

As you might expect, scanning a single object in 3D requires a huge amount of data, which must be processed through 3D scanning software. There are many 3D scanning software packages available online, and the one that works best for you will depend on what you're hoping to achieve.

What Are 3D Scanners Used For?

3D scanners can serve various purposes in many industries, large and small. For example, museums use them to offer 3D renderings of famous artifacts, while manufacturers use them to create production parts. However, some 3D scanners also provide great opportunities for at-home users, too.

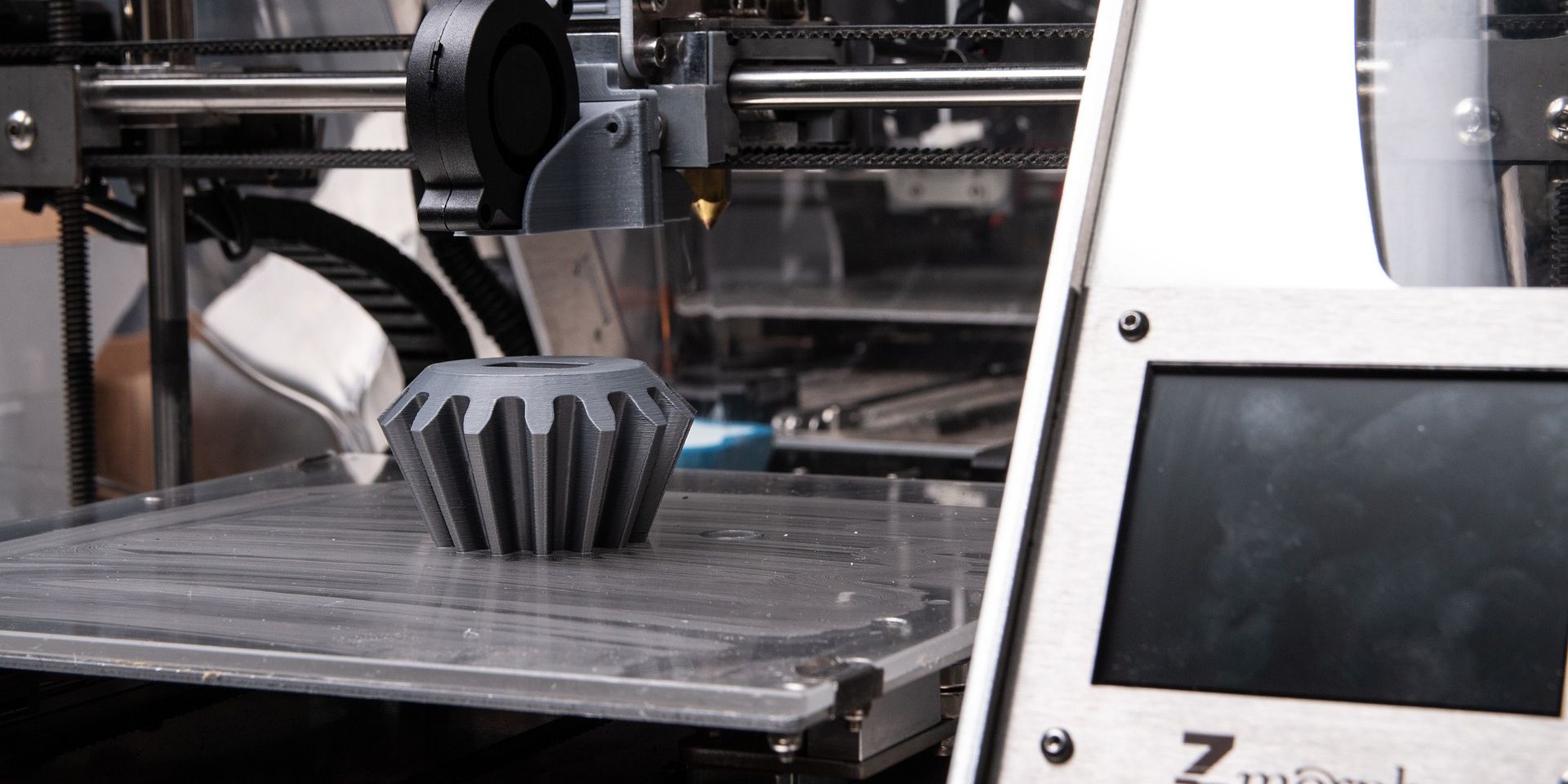

The most obvious is using them with 3D printers to make accurately scaled models or prototypes of existing objects. In addition, these models can be used for fun (e.g., a model-sized replica of one's own car), to capture physical replicas of objects as souvenirs, to replicate everyday objects, or to plan out a future design project.

Even without a 3D printer, a lot can be accomplished with a 3D virtual model. For example, using a virtual model of an object, person, or location allows for the aid in any visual design process. Additionally, any information needed will be provided about a physical space.

The only limitations to what you can do with a 3D scanner are your creativity and the physical capabilities of your 3D scanner. Other than that, anything you can dream of scanning is within your grasp!

Should You Buy a 3D Scanner?

When it comes to 3D scanners, it's safe to say that it's not a matter of if you should buy a 3D scanner but rather a matter of when. However, there are two major factors that you should take into consideration before making the plunge.

Much like the rest of the technology available on the market, 3D scanners have room for improvement. That said, consumer 3D scanners are quite proficient and will accomplish most DIY projects and small-scale applications.

Keep in mind, however, that new variations of 3D scanning technology are developed every day. For example, it has developed so far that modern cellular chips can capture 3D scans, although they lack depth and detail.

While more accessible than ever before, 3D scanners are still beyond what most people are willing to spend. Some quality models can be bought for as little as $600, but most are still in the $1,000+ range—comparable to an upper-tier laptop.

As well, if you don't already own a 3D printer, then you may be limited in what you can do with your 3D scanner. Of course, 3D printing on a budget is always an option, but it's still an additional cost. Entry-level 3D printers can be purchased for roughly $500, whereas higher-quality ones can cost up to a few thousand dollars.

Which 3D Scanner Should You Buy?

There are many 3D scanners on the market, and figuring out what you should buy can be confusing. Here are four 3D scanner options for you to consider.

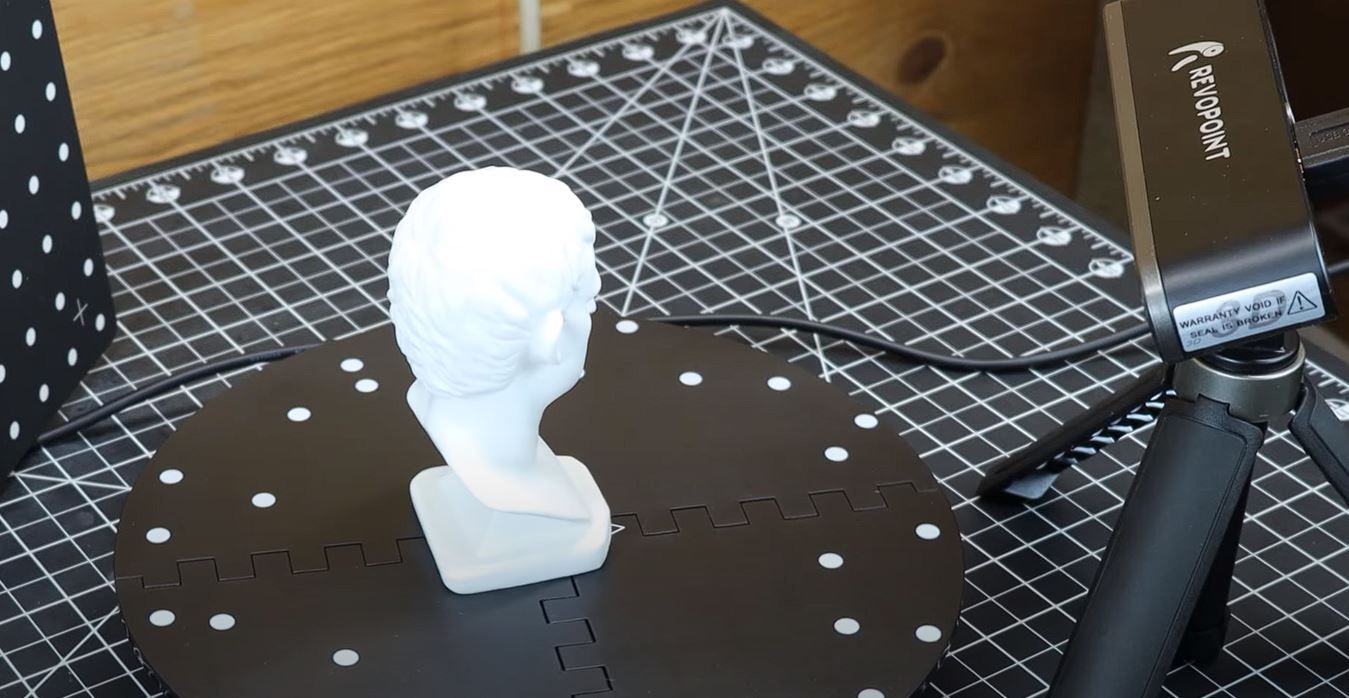

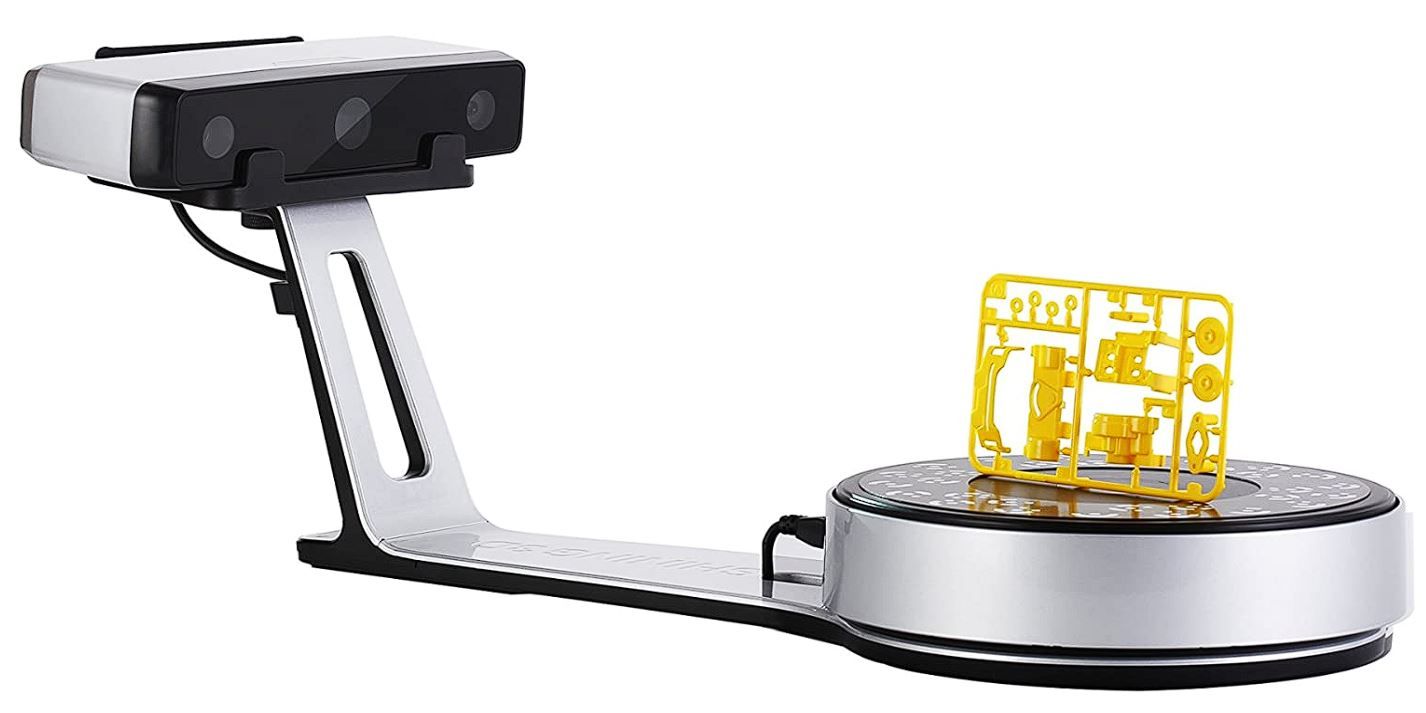

Revopoint 3D Scanners (~$700)

Revopoint has made a name for itself over the budget-friendly 3D scanner they have available on the market. Likewise, with many other revolutionizing products, this alike was crowdfunded as a Kickstarter project and certainly won't be the last.

There are three different models, ranging from capability to price point. The cheapest model captures at 10 FPS, whereas the most expensive option captures at 18 FPS. Despite the minuscule hardware upgrade, it truly expedites the capturing and modeling process, which may prove to be enough of a selling point for some.

Depending on the model you opt for, it boasts an accuracy of either 0.1mm, 0.02mm, or 0.05mm, encapsulating most details and patterns. Since these models are handheld and aren't fixed to a base, they don't have a limited range in what they can scan. This is especially helpful when scanning larger objects.