What went through your mind the first time you saw 3D printing in action? Did you simply think, "Hey that's moderately cool. Oh look, a squirrel"? Or did you think, "Wow. I could build ANYTHING with that!" The very fact that you're reading this article means it's safe to assume that you belong to the latter group.

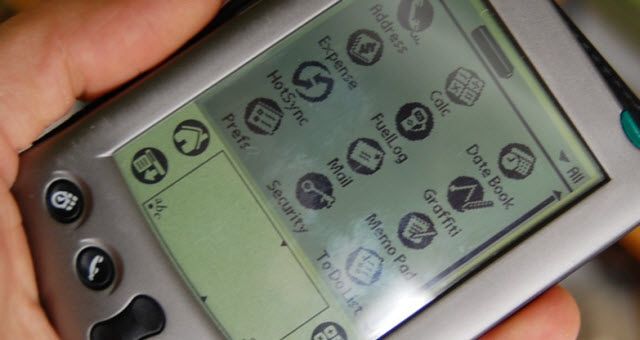

Is it just 'cool' though? Is it just the next big thing like flying cars and meals-in-a-pill? Those are potentially really useful things, yet they never became mainstream. Is that how it's going to go down for 3D printing? Some things like Personal Digital Assistants (PDAs) and Walkman cassette players made the jump from fad to trend, but still faded away. Why?

What Makes a Fad?

What is it that makes an explosively disruptive technology last, while others fade away or never make it out of the gate? There are more criteria for that than we can possibly compile, and many of them just can't be measured, like the 'cool' or luck factors. Ultimately, time decides.

So what happened to the PDA? It could be argued that they were a bit ahead of their time. Computers just weren't everywhere like they are today, and a paper day-planner did everything that most people needed, at least as fast. So actual need and ease-of-use wasn't there.

The Walkman, however, was easy to use and people really wanted to be able to listen to their favourite music, in private, anywhere. There was nothing going against the Walkman until the medium of the music changed. CDs came along and then the rise of the Internet, and MP3s started to make the cassette tape and CD irrelevant. Technology just outpaced the portable tape player, and it evolved into the MP3 players, which were assimilated into the smartphones we love today.

Will those sorts of things happen to 3D printing and rapid prototyping? Unless we can print a working crystal ball or TARDIS, there's no way to know for certain. We can look into the past, however. According to at least a bajillion different historians and philosopher types, history can help us forecast the future.

Why Prototyping Anyway?

The whole idea of designing and prototyping objects is to take our ideas and make them real, see if they work, then change the design to be better. Then we prototype it again, see if it works, then change the design to be even better. This is the feedback loop. Designers, creators, fabricators, artists, and inventors all follow this process.

Prototyping in the Past

In the past, a person would sketch out their idea, making changes on paper. Then they would choose a medium in which to make the item - wood, metal, plastic, whatever. Then they would spend a lot of time working and machining, chiseling and forming, until they got what they thought was a pretty good prototype. Once finished, they'd test it to see if it was as good as possible. If not, it was back to the drawing board. By going through this process just three or four times, it could literally take a year until they had something they were satisfied with. Time IS money, right?!

The drawing part of the process was easy to improve. We came up with standardized drafting techniques and tools. Eventually we had computers and software, so drafting was quicker and making changes was easier. But the fabrication part didn't evolve much. It didn't get better by the leaps and bounds that drafting had.

People tried, though. There are patents for ways of creating 3D items dating back to the late 1800s, but none of them were simple, versatile, or affordable enough to be mass produced.

Photosculpture

One method invented by François Willème and patented in 1864 was the photosculpture. Although it was used mostly for artistic purposes, the idea was there to take an object and quickly duplicate it, if not actually create it. Watch this video of the process being done in 1939, by Marcus Adams. Even today, it is awe inspiring.

CNC and Milling

In the 1940's Numerically Controlled (NC) milling machines could read punch cards and automatically carve the design out of a chunk of metal or wood. This might be considered the start of 3D printing.

In 1951, a Computer Numeric Control (CNC) mill was made at the Massachusetts Institute of Technology (MIT).

CNC mills got better and smaller, but were still too large or expensive for anyone but manufacturers to use. The high speed of the specially designed and super-sharp mill bits were also dangerous, should they break, and they do break often enough. There was nothing that could be used in a fairly small space, safely, and was reasonably affordable until very recently. Take a look at this one.

Real 3D Printing

In the late 1970s to early 1980s, a few smart people came up with an idea for three dimensional printing using polymer resin and light. Being the brainchild of Mitsubishi Motors in 1972, it took until 1981 for Hideo Kodama of Nagoya Municipal Industrial Research to actually do it. It worked by having a bucket of resin slowly move down while lasers were pointed at it from the top and one side. Where the lasers met, the polymer goop hardened. In just a few minutes, you could be holding a resin model of a design that was in your head just that morning.

The following video shows you what is happening in a photopolymer 3D printer. Looking for a more in-depth explanation of how 3D printing works? We have that, too.

You can see this method might not be ideal for use at home. Although photopolymer 3D printing is terrifically accurate, it can be a bit messy if your cat knocks the printer over.

Then came along Fused Deposition Modeling (FDM) printing. To put it into simple terms, it's a printer that squirts out (deposits) melted plastic a little bit at a time. The plastic has to be hot to squirt through a little nozzle, so it sticks (fuses) nicely to the layer of plastic that was previously squirt out. This happens layer after layer until you have a three dimensional object or model. You could do the same thing with hot glue gun if you had nerves of steel and the patience of Gandhi. Or if not, check out the 3Doodler 3D printing pen.

Here's a video of a MakerBot FDM printer in action. MakerBot is one of the major players in bringing 3D printing to the masses. Their printers are small enough to use at home and affordable for many people. But not me, yet.

The State of Prototyping

With 3D printing, CNC milling, and other technologies becoming less expensive, more precise, and easier to use, just about anybody can make their idea into something they can hold in their hand. In doing that, people who have great ideas can bring inventions and products to the market that might never have made it. Like this exoskeleton thingy in the picture below. Looks cool, no idea what it does.

As artists and DIY communities continue to gravitate to 3D printing, we are seeing exponential adaptation.

"Everyday, more people have access to 3D-printing technology thanks to the open-source hardware DIY clubs, hacker and maker spaces and Maker Faires that (keep) popping up in cities around the globe. Good international examples are Wevolver in London and Amsterdam, the FabLabs, and the more recently, the 3D Hubs network, which grew from connecting a couple of hundred 3D-printers to more than 7,000 in less than a year's time." notes Rudy de Waele, Technology Innovation Strategist and Author/Curator of Shift 2020.

3D Printing as a Business Model

Right now there are thousands, if not millions, of files on the Web that you can just load into your 3D printer and make the item. You don't even need to know how to design anything.

As Richard A. D'Aveni explains in the Harvard Business Review article, 3-D Printing Will Change the World,

"As applications of the technology expand and prices drop, the first big implication is that more goods will be manufactured at or close to their point of purchase or consumption. This might even mean household-level production of some things. (You'll pay for raw materials and the IP—the software files for any designs you can't find free on the web.)"

What effect will that have on the transportation, retail, and aftermarket service markets? It's hard to say, but if it saves businesses and people money, it's usually a safe bet it will catch on.

Will it Stay or Will it Go?

We've seen that there has a been a long standing demand for 3D printing and that it does save people time, energy, and money. We've also seen that there are a few ways that 3D printing and prototyping can be done - CNC machines, photopolymers, and FDM are just three that are available. So, the medium might change, but the essential 3D printing processes will continue. The process is also becoming more portable, easier to do, and more affordable almost daily.

Perhaps even more importantly, 3D printing and rapid prototyping opens doors for people who might not have considered design or engineering before. Dave Evans, Silicon Valley Futurist states such in 5 Experts Weigh In on the Future of 3D Printing,

"3D printing does something very few other technologies do – it combines art and science. What a great way to get key women (and men) involved now regardless of background."

There's even a $100 3D printer that should be available soon. With that much going for it, and the ingenuity of the items being created with 3D printing, it certainly seems like it's here to stay with us, at least as long as the Walkman...if not longer.

What do you think? Fad or Future? Any plans for getting a 3D printer or CNC mill for yourself? Do you already have one? If you do, what do you use it for? Would you recommend other people trying 3D printing out? Let us know, down below.

Image Credits: Milling Machine Via Shutterstock, 3d printer Via Shutterstock, WREX exoskeleton at the 3D printing the future exhibition at the Science_Museum in London, Drafting Room, Sony Walkman, Older CNC Machine via WikiMedia, Palm Vx via Flickr