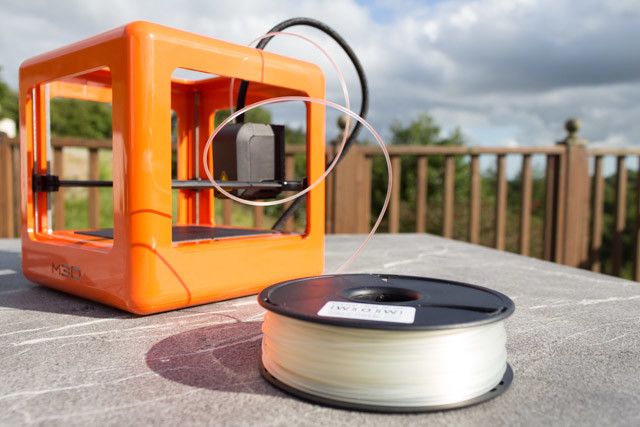

M3D Micro

A fully assembled consumer friendly 3D printer is now within your grasp: at the time of the original Kickstarter, a $350 3D printer was basically unheard of, even with DIY kits. That's why in 2014 they surpassed their funding goal of $50,000 in 11 minutes. We've finally got our hands on one, and it's actually pretty good.

Fancy owning your own 3D printer? At the end of this review we'll be giving away our M3D Micro test unit to one lucky reader!

http://youtu.be/6vJbd9li_Zw

Design and Specs

The Micro part of the name isn't kidding: this thing is tiny. Here's a banana for scale.

- Print Quality: from 50 to 350 microns layer thickness

- Build Area: 109mm x 113mm at the base, but reduced to 91mm x 84mm above a height of 74mm, up to a total of 116mm.

- Printer Size: 185mm cube.

Despite the overall small print size, I found it impressive how little space the printer took up on top of that – it's built to make the most effective use of the space as possible, even down to a discreetly hidden area under the print bed for a filament spool to be seated.

My First Print

Although there is that space under the print bed with a tube connecting it to the extruder, it's actually recommended you use the external feed port. There's no spool holder when used externally, but M3D do provide a 3D model of one that you can print out. In curious way, this was actually quite satisfying. The excitement of having a 3D printer can sometimes extinguish quickly as you're overwhelmed by a catalogue of 3D printables from the Thingiverse or similar repositories. With the Micro, you know exactly what you need to print first, and it feels like quite the achievement to have printed a spool holder – something useful that you can point at and justify your extravagant purchase. Even if one should have been included anyway.

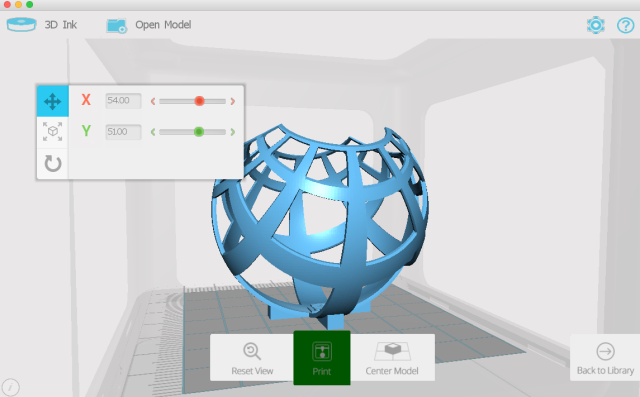

The software is incredibly easy to use, walking you through ink change procedures and reducing the complicated processing of sliding models into a simple case of click a button to load a 3D model, resize or rotate as you wish, then hit print and choose the quality.

Print Quality – ABS and PLA

Like the Cubify I reviewed last year, the Micro doesn't come with a heated print bed, which results in ABS prints cooling rapidly and warping upwards before the print is finished – you can see an example of this in the video. This ends in a sticky mess of 3D printed spaghetti, and the Micro is no different – I was unable to print anything large or small directly onto the print bed. When used with a BuildTak surface applied, I did have some success on smaller ABS prints, but if you're looking specifically to print in ABS I would advise you look elsewhere.

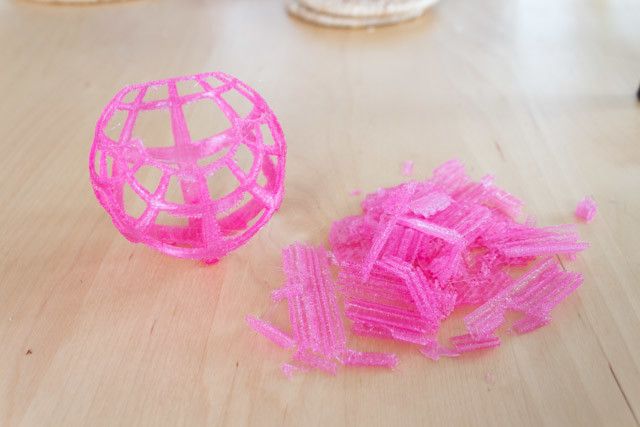

PLA is a different matter, and can be printed just fine onto non-heated print beds. Anecdotally, the detail on the PLA prints rivals that of the $1000 Cubify 3D, and that's a great achievement for something one-third of the price (and without the hassle of DRM'ed print cartridges). Both small and large PLA prints came out well, though again, I would still suggest a BuildTak surface anyway for easier removal and to prevent damage to the print bed.

The low poly dinosaur you see above was printed on high quality with a medium fill, and took approximately 8 hours to complete. The most intricate print I managed to get out the M3D was this stereographic projection sphere, which also happens to demonstrate perfectly the amount of plastic waste you'll create due to the various support rafts that are needed for a model like this. I really hope they have a way of recycling this stuff soon.

"Ink"

The Micro takes any standard 1.75mm ABs or PLA filament. It's mildly frustrating that M3D have decided to call filament "3D ink", but there you go. Branded spools cost $13 for 225g. The upside to purchasing their branded filaments is a "cheat code" on every spool, which the software will use to derive the optimal print settings from - temperature, material type, etc. If you do decide to load in third party filament, you'll need to figure that out yourself, or source something similar. That's not to imply this would be a difficult task to find out those details, but merely that a 3 letter code is definitely easier and it's one less worry.

Setup Woes

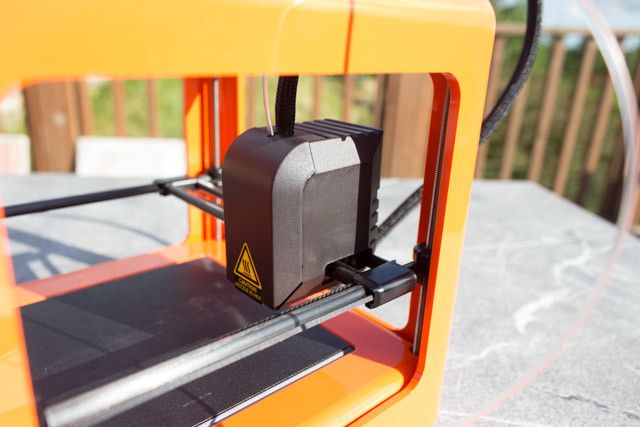

Anyone who's experienced a 3D printer will tell you that it's not all roses: half the time will be spent re-calibrating, sorting out nozzle jams, or filament feed issues. Such is the nature of 3D printing by heated plastic filament extrusion. As new 3D printing techniques are refined (or rather, pulled down to a consumer level of affordability), these problems will likely be replaced by others – but for now, this is the playing field you choose. Even a $2000 MakerBot Replicator isn't immune to nozzle jams. I will say this for the M3D Micro though: not once did I experience a nozzle jam. This may have just been luck, but it probably also down to rapid improvement in the core technologies used in the extruder and heating nozzle.

What wasn't so obvious was the calibration. Attempting to auto-calibrate fires up a warning message about damaging the printer if you don't use a BuildTak. I had no idea what that was, and one isn't included. It turns out they're basically a layer of flexible plastic you place onto the build bed to provide better adhesion for print. Each one costs around $10 and is reusable a number of times, so after purchasing one I finally managed calibration. The BuildTak sheet itself comes with instructions to raise the height of your base layer a few hundredths of a millimeter higher – but upon doing so, whatever auto-calibration had occurred was apparently lost, and the next print saw the hot nozzle plummet directly into the BuildTak sheet, burning a hole directly through it and into the print bed. I'll have a replacement sent to the winner, I promise. It turns out only the auto-calibration is necessary, but no worries – it works fine with a new sheet of the BuildTak applied.

Alternatives

A year earlier, the Pirate3D Buccaneer had made a similar claim, offering a $300 3D printer and gathering over a $1.3 million on Kickstarter. Today they're deluged in a torrent of refund requests and lawsuits on a product they ultimately couldn't deliver. They've moved on to peddling their device for closer to $1000, so it's no longer a competitor to the Micro and may not even exist at all.

It's also worth mentioning HobbyKing has launched that a similar form factor fully assembled 3D printer called the Mini Fabrikator, for only $180.

For those more technically inclined who think they could handle constructing a 3D printer in kit form, you might want to look at an open source kit instead, such as this Kossel DLT-180 delta-style printer for $300 including delivery from China. The build area is larger and supposedly the print quality is better, plus there's a vibrant community out there to aid with any problems and a multitude of upgrade options.

Is This The 3D Printer You're Looking For?

Even facing stiff competition from open source 3D printer kits, the M3D Micro is an affordable way to take your first steps into 3D printing – and surprisingly produces prints that are on par or better than the $1000 "budget" Cubify printer we looked at last year. The Micro comes fully assembled, so if you're looking for the cheapest 3D printer around that comes packaged and ready for consumer use, I see no reason to grab one now before the price increases (I say that because the website implies it might, though who knows). The only sacrifice is the small build area, though while testing the printer I didn't come across many objects that required a larger area, or that couldn't be suitably scaled down. If you need specifically to print in ABS, or anything over the size of a 10cm cube, then look elsewhere.

[recommend]The M3D Micro is the most affordable consumer-ready 3D printer we've seen yet. There are cheaper open source kits out there if the small build area is too limiting for you, but if you just want to get started without spending thousands of dollars, we see no reason not to grab an M3D Micro now![/recommend]

Send your products to be reviewed. Contact James Bruce for further details.